CEMS Flue Gas Online soj ntsuam nrog Microporous Sintered Lim

Flue gas xyuas stainless hlau microporous sintered lim caij

Flue gas xyuas stainless hlau microporous sintered lim caij

Sintered lim caij lim raj rau Cems flue gas online xyuas thiab purification system

Lub microporous stainless hlau hmoov sintered lim raj rau me me molecule pom yog ua los ntawm stainless hlau hmoov pressed los ntawm ib tug pwm, sintered ntawm kub, thiab integrally tsim.Nws muaj qhov zoo ntawm lub zog txhua yam, qhov kub thiab txias tsis kam, zoo corrosion kuj, zoo pore loj faib, zoo huab cua permeability, huv si regeneration, thiab vuam tshuab machining.Kho cov hmoov particle loj thiab cov txheej txheem cov txheej txheem ua rau nws muaj peev xwm tsim tau porous hlau sintered lim ntsiab nrog ntau yam kev pom tseeb.Vim muaj ntau yam zoo ntawm porous hlau hmoov sintered cov ntaub ntawv, hom khoom no yog dav siv nyob rau hauv catalyst rov qab, gas-kua lim, thiab kev sib cais nyob rau hauv lub teb ntawm tshuaj lom neeg kev lag luam, tshuaj, dej haus, zaub mov, metallurgy, roj av, ib puag ncig tiv thaiv. fermentation;ntau yam gases, plua plav tshem tawm, kom tsis muaj menyuam, thiab tshem tawm cov roj pos huab;txo suab nrov, nplaim taws ntes, roj buffering, thiab lwm yam.

Nta:

Nta:

1. Cov duab ruaj khov, cuam tshuam tsis kam, thiab alternating load peev yog zoo dua li lwm cov ntaub ntawv hlau lim;

2. Huab cua permeability, kev sib cais ruaj khov;

3. Zoo heev loading thiab unloading zog, haum rau siv nyob rau hauv high kub, siab kub, thiab muaj zog corrosive ib puag ncig;

4. Tshwj xeeb tshaj yog haum rau high-temperature gas filtration;

5. Cov khoom ntawm ntau yam duab thiab precision tuaj yeem hloov kho raws li cov neeg siv khoom xav tau, thiab ntau yam kev sib tshuam tuaj yeem siv los ntawm vuam.

Kev ua tau zoo: acid tsis kam, alkali tsis kam, siab kub tsis kam, tsis kub tsis kam, tiv thaiv hluav taws, tiv thaiv zoo li qub

Qhov chaw ua haujlwm: Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, kua hydrogen, kua nitrogen, hydrogen sulfide, acetylene, dej vapor, hydrogen, roj, carbon dioxide gas, thiab lwm yam ib puag ncig.Nws muaj ntau yam porosity (28% -50%), pore loj (0.2um-200um), thiab pom tseeb (0.2um-100um), nrog criss-cross channel, siab-kub kuj, thiab ceev ceev cua txias thiab kub tsis kam. .Anti-corrosion.Nws yog tsim rau ntau yam corrosive media xws li acids thiab alkalis.Stainless hlau lim caij tuaj yeem tiv taus cov kua qaub-puag thiab cov organic corrosion, uas yog tshwj xeeb tshaj yog haum rau lim sulfur-muaj gases.Nws muaj lub zog siab thiab zoo toughness.Nws yog qhov tsim nyog rau qhov chaw muaj kev kub ntxhov.Nws tuaj yeem welded.Yooj yim rau thauj thiab unload.Stable pore zoo thiab uniform tis kom ruaj khov pom kev ua tau zoo.Kev ua tau zoo dua qub.Tom qab rov ua dua thiab rov tsim dua tshiab, qhov pom kev ua tau zoo rov qab los ntawm ntau dua 90%.

Ua haujlwm kub: ≤900 ° C

Phab ntsa thickness: feem ntau 3 hli

Internal siab: 3mpa

Khoom siv: 304, 304L, 316, 316L.

Plua plav particle sib cais, purification, thiab Lim Stainless hlau hmoov sintered lim caij muaj txiaj ntsig zoo xws li kev tiv thaiv corrosion, kub-resistant, siab zog, yooj yim kev ruaj ntseg pom tseeb, thiab ib qho yooj yim regeneration.Lub titanium lim caij yog ua los ntawm titanium hmoov tom qab molding thiab high-temperature sintering, yog li cov khoom nto tsis yooj yim poob;kev siv hauv huab cua tuaj yeem ncav cuag 500-600 ° C;Nws yog tsim rau lim ntau yam corrosive media, xws li hydrochloric acid, sulfuric acid, Lim hydroxide, seawater, aqua regia thiab chloride daws xws li hlau, tooj liab, thiab sodium.Nws muaj cov cuab yeej zoo heev, tuaj yeem siv rau kev txiav, vuam, thiab lwm yam, muaj zog compressive siab, thiab nws qhov tseeb pom tau yooj yim los xyuas kom meej.Lub pore txoj kab uas hla yuav tsis deformed txawm tias nws ua haujlwm nyob rau hauv qhov kub thiab txias.Nws cov porosity tuaj yeem ncav cuag 35-45%, qhov pore loj faib yog qhov sib xws thiab cov av tuav lub peev xwm loj, thiab cov txheej txheem rov ua dua tshiab yog qhov yooj yim thiab tuaj yeem rov siv dua tom qab tsim dua tshiab.

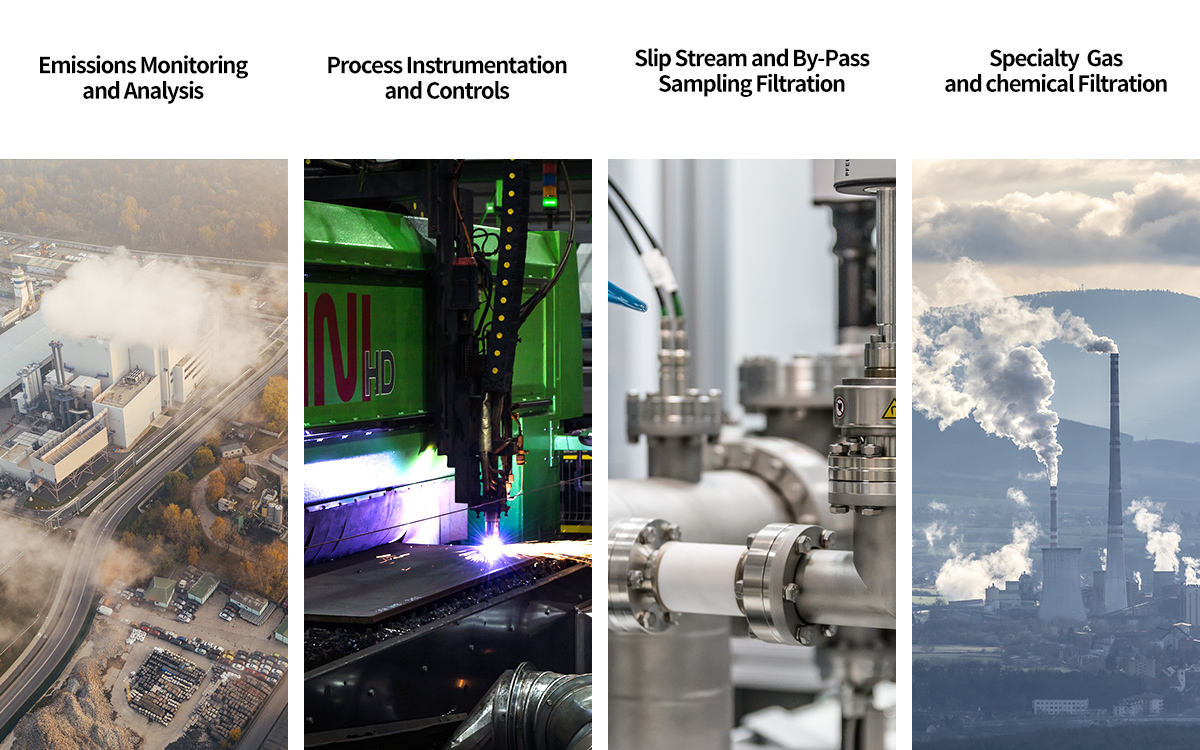

Plua plav particle sib cais, purification, thiab Lim stainless hlau hmoov sintered lim caij muaj kev ua tau zoo heev.Nws tuaj yeem siv dav hauv kev lag luam tshuaj, kev lag luam kho dej, kev lag luam khoom noj, kev lag luam lom neeg, tshuaj lom neeg kev lag luam, kev lag luam petrochemical, kev lag luam metallurgical, thiab roj purification.Nws yog ib yam khoom tshiab nrog rau txoj kev loj hlob dav dav.

Cov kev siv ib txwm muaj xws li:

1. Nyob rau hauv kev lag luam kws tshuaj, nws yog siv rau decarbonization pom nyob rau hauv cov concentrated npaj txheej txheem ntawm loj infusion daws, me me txhaj tshuaj, qhov muag tee, thiab cov kua qhov ncauj thiab kom muaj kev ruaj ntseg ua ntej lub davhlau ya nyob twg pom nyob rau hauv lub diluted npaj txheej txheem.

2. Kev tshem tawm impurity thiab lim nyob rau hauv cov txheej txheem ntawm cov khoom siv raw, decarbonization pom, thiab lim cov ntaub ntawv zoo.

3. Kev lim dej nyab xeeb rau ultrafiltration, RO, thiab EDI systems hauv kev lag luam kho dej, Lim tom qab ozone sterilization, thiab ozone aeration.

4. Kev nthuav qhia thiab pom cov dej haus, cawv, npias, roj zaub, dej ntxhia, kua ntses, thiab vinegar hauv zaub mov thiab dej haus.

5. Decarbonization pom thiab precision pom ntawm cov khoom ua kua, kua raw cov ntaub ntawv, thiab tshuaj intermediates nyob rau hauv cov tshuaj kev lag luam, pom thiab rov qab ntawm ultra-fine particles thiab catalysts, precision pom tom qab resin adsorption, thiab impurity tshem tawm thiab pom ntawm lub cev kub hloov roj. thiab cov ntaub ntawv, catalysis Gas purification, thiab lwm yam.

6. Oilfield rov qab lim dej thiab seawater desalination teb ua ntej rov qab osmosis kom muaj kev nyab xeeb pom.

7. High-temperature decarbonization thiab dawb av nplaum pom hauv kev lag luam dyeing.

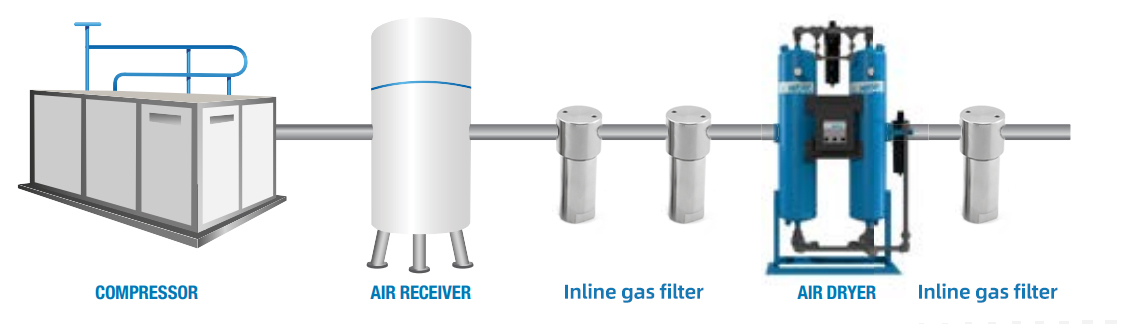

8. Nyob rau hauv cov nqe lus ntawm cov pa purification, nws mas muaj xws li purification thiab pom ntawm chav, compressed cua, thiab catalytic gas.

FAQ

1. Lub siab purity semiconductor roj lim yog dab tsi?

Lub siab purity semiconductor roj lim yog ib hom tshwj xeeb ntawm cov lim tsim los tshem tawm impurities los ntawm cov roj siv hauv kev tsim cov khoom siv hluav taws xob.Cov lim dej no yog tsim los ntawm cov ntaub ntawv uas tuaj yeem tiv taus qhov kub thiab txias thiab cov tshuaj corrosive, thiab tsim los tshem tawm cov khoom mus rau qib nano-scale.

2. Vim li cas lub siab purity semiconductor roj lim tseem ceeb?

Hauv kev tsim khoom ntawm semiconductors, txawm tias me me ntawm impurities tuaj yeem ua rau muaj qhov tsis xws luag thiab txo qhov zoo ntawm tag nrho cov khoom kawg.High purity semiconductor gas filters pab xyuas kom meej tias cov roj siv hauv kev tsim cov txheej txheem tsis muaj kab mob, ua rau cov khoom siv hluav taws xob zoo dua.

3. Dab tsi ntawm cov roj lim tuaj yeem lim tau nrog cov roj purity semiconductor siab?

High purity semiconductor roj lim tuaj yeem siv los lim ntau cov pa roj, suav nrog hydrogen, nitrogen, oxygen, thiab ntau yam txheej txheem gases.Nyob ntawm cov txheej txheem tsim khoom tshwj xeeb, cov lim dej sib txawv yuav tsum ua kom tiav qib siab ntawm purity.

4. Yuav ua li cas cov purity semiconductor roj lim ua?

High purity semiconductor gas lim yog tsim los ntawm cov ntaub ntawv xws li stainless hlau, thiab lwm yam hlau muaj zog.Cov ntsiab lus lim yog feem ntau me me, nrog qhov pore loj li ntawm 0.1 txog 1 micron.Cov lim dej feem ntau yog coated nrog cov ntaub ntawv tshwj xeeb los txhim kho lawv cov khoom nto thiab txhim kho lawv cov kev ua haujlwm pom.

5. Ntev npaum li cas cov purity semiconductor roj lim kav ntev?

Lub neej ntev ntawm lub siab purity semiconductor roj lim tuaj yeem sib txawv nyob ntawm ntau yam, suav nrog hom lim, roj lim, thiab cov txheej txheem tsim khoom tshwj xeeb.Feem ntau, cov ntxaij lim dej no yog tsim los siv rau lub sijhawm ntev thiab tuaj yeem kav ntev li ob peb lub hlis lossis ntau xyoo ua ntej yuav tsum tau hloov.Kev tu thiab tu tsis tu ncua tuaj yeem pab ua kom lub neej ntev ntawm cov lim dej no thiab ua kom pom kev ua haujlwm zoo nyob rau lub sijhawm.