-

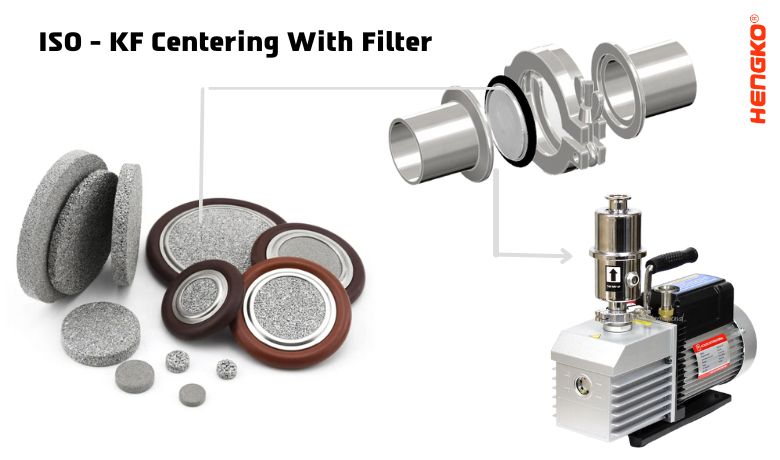

NW16 KF16 Flange-Centering O-Ring nrog Fine Lim

ISO-KF thiab NW Sintered Hlau Lim Centering Nplhaib NW-16, NW-25, NW-40, NW-50 Tus neeg xa khoom Nrog cov lim zoo (sintered ntxeem tau hlau lim lossis xaiv hlau mesh f ...

Saib nthuav dav -

NW50 KF50 Nqus Flange Centering nplhaib nrog Sintered Hlau Lim, stainless hlau, 50 ...

NW50 KF50 Centering nplhaib nrog Sintered Hlau Lim, stainless hlau, 50 ISO-KF Khoom siv: stainless hlau 304,316 Kev teeb tsa txoj kev: siv nrog clam ...

Saib nthuav dav -

NW25 KF25 KF Centering Nplhaib rau Sintered Hlau Lim

NW25 KF25 KF Centering Nplhaib rau Sintered Hlau Lim • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Pore Size• F...

Saib nthuav dav -

Nqus KF certering nplhaib nrog Sintered Hlau Lim

Khoom Piav Qhia Lub Flange Connections Centering rings nrog Sintered Hlau Lim nyob rau hauv lub tshuab nqus tsev yog siv mus txog rau lub tshuab nqus tsev siab ntawm 10 mus rau -7 mbar ...

Saib nthuav dav -

sintered hlau stainless hlau lim nrog centering nplhaib siv los tsim foreline vacuu ...

Code Flange HKF10 NW10KF HKF16 NW16KF HKF20 NW20KF HKF25 NW25KF HKF40 NW40KF HKF50 NW50KF HENGKO centering nplhaib sib dhos nrog sintered ...

Saib nthuav dav -

Tshiab lub tshuab nqus tsev lub nplhaib iso npo, sintered ntxeem tau hlau lim

Centering rings nrog Sintered Hlau Lim yog cov qauv siv rau txhua lub tshuab nqus tsev thiab lub tshuab nqus tsev siab. Centering rings nrog sintered hlau lim ...

Saib nthuav dav

Main Features thiab Applications

Suction lim rau lub tshuab nqus tsev twj thiab compressors

Yuav los yog Kho koj lub nplhaib Centering KF10, KF16, KF25, KF40 txawm - KF160 SS 316L, FKM O'ring, nrog mesh npo lossis Sintered hlau lim rau koj lub tshuab nqus tsev twj tso kua mis ntawm HENGKO. Tau tshaj 20 hom ntawm lub tshuab nqus tsev twj lossis compressors, tus nqi Hoobkas tiag, 50% pheej yig dua li kev lag luam.

Qee Daim Ntawv Thov Ntawm Lub Nplhaib Nruab Nrab

1. Eco Lim:

Cov ntxaij lim dej raug nqi zoo sib xws nrog txhua tus qauv ntawm lub tshuab nqus tsev twj los ntawm ntau lub tuam txhab. Cov khoom sib hloov tau muaj xws li:

1. Daim ntawv (6μm).

2. Washable polyester (10μm).

3. Washable pleated stainless hlau daim ntaub (60μm).

4. Cov pa roj carbon activated (rau ntxiab condensable vapors).

Cov lim dej yog tsim los ntawm carbon steel thiab coated nrog epoxy xim.

Lawv feature ib tug poj niam threaded kev twb kev txuas mus rau lub gas pitch thiab kaw los ntawm hooks.

5. Air Inlet Filters: Cov lim dej pheej yig rau huab cua inlet ntawm compressors. Cov khoom sib hloov tau suav nrog ntawv (6μm),

washable polyester (10μm), thiab washable pleated stainless hlau ntaub (60μm). Cov lim yog tsim nrog

carbon hlau thiab coated nrog epoxy xim. Lawv txuas los ntawm lub dab tshos lossis threaded raj nrog lub suab nrov.

2. Roj Da Dej Lim:

Tsim los rau mounted rau ntawm suction sab ntawm lub tshuab nqus tsev twj lossis compressors, cov ntxaij lim dej no tiv thaiv cov cuab yeej los ntawm cov hmoov av ntau. Tshem tau, ntxuav tau, thiab muaj qhov ntau thiab tsawg los ntawm 1/2 "G mus rau 2" G. Cov lim dej yog tsim los ntawm carbon steel thiab coated nrog epoxy xim. Lawv feature ib tug poj niam threaded kev twb kev txuas mus rau lub gas pitch.

Visi-trap:

Suction lim rau lub tshuab nqus tsev twj nrog lub cev pob tshab (SAN). Cov khoom lim tuaj nyob rau hauv ob qhov ntau thiab tsawg: 4.5 "thiab 9.5" NPT poj niam lossis KF25 thiab KF40. Muaj 8 txoj hauv kev rau lim cov ntsiab lus: tooj liab straw (rau condensable hais thiab vapors), stainless hlau straw (rau condensable hais thiab vapors nrog zoo corrosion kuj), molecular sieve (rau tshem tawm backscattering los ntawm mechanical twj thiab tiv thaiv lub twj tso kua mis los ntawm chav dej) , sodium txiv qaub (rau kho corrosive lossis acidic khoom), activated carbon (rau kho cov organic vapors), polypropylene 2μm, 5μm, thiab 20μm (rau cov khoom thiab ntxuav tau).

Posi-trap:

Suction lim rau stainless hlau nqus twj tso kua mis muaj nyob rau hauv ob qhov ntau thiab tsawg: DN100 (1 lim caij) thiab DN200 (4 lim ntsiab). Kev sib txuas tuaj yeem yog kab lossis 90 ° thiab muaj nyob rau hauv KF25, KF40, thiab KF50. Cov ntsiab lus lim tuaj nyob rau hauv 8 txoj kev xaiv: tooj liab straw (rau condensable hais thiab vapors), stainless hlau straw (rau condensable hais thiab vapors nrog zoo corrosion kuj), molecular sieve (rau tshem tawm backscattering los ntawm mechanical twj thiab tiv thaiv lub twj tso kua mis los ntawm chav dej) , sodium txiv qaub (rau kho corrosive los yog acidic khoom), activated carbon (rau kho cov organic vapors), polypropylene 2μm, 5μm, thiab 20μm (rau cov khoom thiab ntxuav tau).

Multi-cuav:

Suction lim rau lub tshuab nqus tsev ua haujlwm siab rau kev thov (LPCVD, PECVD, ALD, MOCVD, Hlau Etch, HVPE, extrusion, thiab lwm yam) uas tsim cov khoom loj thiab cov vapors. Cov ntxaij lim dej no tuaj nyob rau hauv peb qhov ntau thiab tsawg, tag nrho nrog stainless hlau tsim, thiab muaj ntau yam kev xaiv, suav nrog ntau theem thiab txias coil. Cov ntsiab lus lim tuaj nyob rau hauv 8 txoj kev xaiv: tooj liab straw (rau condensable hais thiab vapors), stainless hlau straw (rau condensable hais thiab vapors nrog zoo corrosion kuj), molecular sieve (rau tshem tawm backscattering los ntawm mechanical twj thiab tiv thaiv lub twj tso kua mis los ntawm chav dej) , sodium txiv qaub (rau kho corrosive los yog acidic khoom), activated carbon (rau kho cov organic vapors), polypropylene 2μm, 5μm, thiab 20μm (rau cov khoom thiab ntxuav tau). Cov ntsiab lus lim tuaj yeem siv ib leeg lossis ua ke rau ntau theem qauv.

Daim ntawv thov

KF (Klein Flange) lub nplhaib nruab nrab nrog cov lim dej yog qhov tseem ceeb hauv kev siv lub tshuab nqus tsev, ua lub luag haujlwm tseem ceeb hauv kev sib khi thiab pom. KF nruab nrab lub nplhaib sib dhos thiab kaw lub tshuab nqus tsev flanges, thiab cov lim dej ua kom cov kab mob nkag mus rau hauv lub cev. Nov yog qee qhov kev siv:

1.Semiconductor Chaw Tsim Khoom:

2. Mass Spectrometry:

3. Pharmaceutical Manufacturing:

4. Material Science thiab tshawb fawb:

5. Chaw Simulation Chambers:

Hauv tag nrho cov ntawv thov no, KF lub nplhaib nruab nrab nrog cov lim kom muaj kev ruaj ntseg foob thiab tiv thaiv kev nkag mus rau hauv lub tshuab nqus tsev. Nws yog ib qho me me uas muaj kev cuam tshuam loj rau kev ntseeg tau thiab qhov tseeb ntawm ntau lub tshuab nqus tsev thiab kev sim.

Txaus siab rau kev txhim kho koj lub tshuab nqus tsev nrog peb cov khoom zoo tshaj plaws OEM KF Centering Rings nrog Lim?

Peb xav hnov los ntawm koj! Txawm li cas los xij koj daim ntawv thov, peb pab pawg kws tshaj lij nyob ntawm tes los muab cov ncauj lus kom ntxaws thiab cov kev daws teeb meem kom tau raws li koj cov kev xav tau tshwj xeeb.

Coj koj cov haujlwm mus rau qib tom ntej nrog peb cov khoom ua tau zoo, tsim kom muaj kev ntseeg siab thiab raug. Tsis txhob cuam tshuam rau qhov zoo - xaiv peb KF Centering Rings nrog Lim kom tau txais txiaj ntsig zoo hauv koj daim ntawv thov lub tshuab nqus tsev.

Yog xav paub ntxiv thiab sib tham txog koj cov kev xav tau tshwj xeeb, hu rau peb hnub no ntawmka@hengko.com. Peb tab tom tos ntsoov yuav koom tes nrog koj kom ua tiav qhov zoo tshaj plaws hauv koj txoj kev lag luam!

Txhua Yam Koj Yuav Tsum Paub Txog

KF Centering Nplhaib Nrog Lim rau Lub Tshuab Nqus Tsev

KF Centering Ring With Filter yog cov khoom siv hauv lub tshuab nqus tsev twj los tiv thaiv lub twj tso kua mis los ntawm cov khib nyiab

thiab particle. Nws yog ib qho tseem ceeb ntawm lub tshuab nqus tsev twj tso kua mis kom ua haujlwm zoo thiab ua haujlwm ntev.

Yog vim li cassiv lub KF Centering Nplhaib Nrog Lim

1. Tiv thaiv kev puas tsuaj rau lub tshuab nqus tsev twj:

Cov khib nyiab thiab cov khoom me me tuaj yeem ua rau cov khoom siv sab hauv ntawm lub tshuab nqus tsev vacuum, ua rau

txo kev ua haujlwm, nce hnav thiab tsim kua muag, thiab muaj peev xwm tawg. KF Centering nplhaib nrog

Filter zoo ntxiab cov kab mob no, tiv thaiv lawv los ntawm kev nkag mus rau hauv lub twj tso kua mis thiab ua rau muaj kev puas tsuaj.

2. Extends lifespan ntawm lub tshuab nqus tsev twj:

Los ntawm kev tiv thaiv kev puas tsuaj los ntawm cov khib nyiab thiab cov khoom me me, KF Centering Ring With Filter pab txhawb

mus rau tag nrho lub neej ntev ntawm lub tshuab nqus tsev twj tso kua mis, txo cov nqi txij nkawm thiab xav tau kev hloov ntau zaus.

3. Txhim kho lub tshuab nqus tsev zoo:

Cov khib nyiab thiab cov teeb meem tuaj yeem cuam tshuam nrog kev ua haujlwm zoo ntawm lub tshuab nqus tsev twj, txo nws txoj haujlwm.

suction peev thiab tsim kev hloov pauv hauv lub tshuab nqus tsev. KF Centering Ring Nrog Lim pab tswj

zoo ib yam thiab zoo lub tshuab nqus tsev ua haujlwm.

Ntantawm KF Centering Nplhaib Nrog Lim

1. Stainless hlau siv:

KF Centering Rings Nrog Lim feem ntau yog tsim los ntawm cov hlau tsis muaj steel,

kom ntseeg tau tias tiv thaiv corrosion thiab hnav thiab tsim kua muag, txawm tias nyob rau hauv ib puag ncig hnyav.

2. Sintered hlau lim:

Cov khoom lim feem ntau yog ua los ntawm cov hlau sintered, cov khoom siv tshwj xeeb nrog a

porous qauv uas zoo cuab cov khib nyiab ntawm ntau qhov ntau thiab tsawg.

3. O-ring seal:

Lub O-ring foob muab kev sib txuas nruj thiab xau-pov thawj ntawm KF Centering Ring Nrog

Lim thiab lub tshuab nqus tsev twj tso kua mis flange, tiv thaiv cov pa tawm uas tuaj yeem cuam tshuam kev ua haujlwm ntawm lub tshuab nqus tsev.

4. Ntau qhov ntau thiab tsawg thiab teeb tsa:

KF Centering Rings Nrog Lim muaj nyob rau hauv ntau qhov ntau thiab tsawg

configurations kom phim txawv lub tshuab nqus tsev twj qauv thiab flange ntau thiab tsawg.

Muaj nuj nqintawm KF Centering Nplhaib Nrog Lim

1. Kev sib tw:

KF Centering Nplhaib Nrog Lim aligns lub tshuab nqus tsev twj flange nrog lub flange txuas,

ua kom muaj kev sib haum xeeb thiab tiv thaiv kev tsis sib haum xeeb uas tuaj yeem ua rau xau lossis puas tsuaj.

2. Lim:

Cov sintered hlau lim ntxiab cov khib nyiab thiab cov khoom me me thaum huab cua lossis roj dhau los ntawm

KF Centering Ring Nrog Lim, tiv thaiv lub tshuab nqus tsev twj los ntawm kev sib kis.

3. Sealing:

Lub O-ring foob tiv thaiv cov pa tawm ntawm KF Centering Ring Nrog Lim thiab flanges,

tswj lub tshuab nqus tsev siab hauv qhov system.

XaivTxoj Cai KF Centering Nplhaib Nrog Lim

1. Xav txog lub tshuab nqus tsev twj qauv:

Xyuas kom meej tias KF Centering Nplhaib Nrog Lim yog sib xws nrog cov qauv tshwj xeeb thiab qhov loj ntawm koj lub tshuab nqus tsev twj.

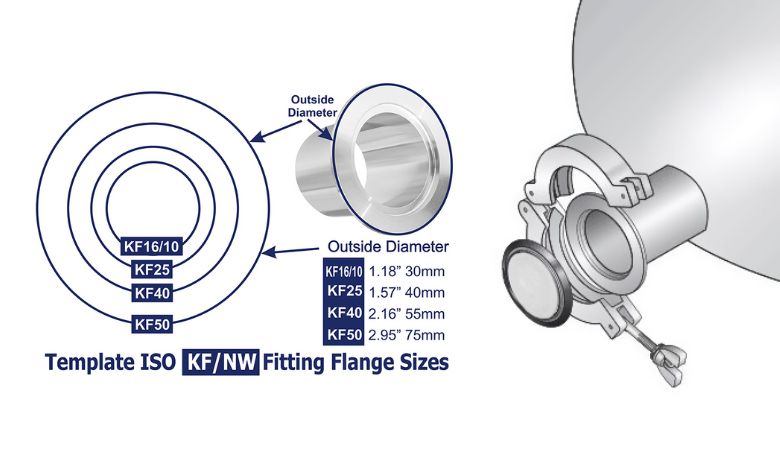

2. Ua raws li flange loj:

KF Lub Nplhaib Nruab Nrab Nrog Lim yuav tsum sib phim txoj kab uas hla ntawm lub tshuab nqus tsev twj flange thiab cov flange txuas los xyuas kom haum.

3. Xaiv qhov tsim nyog lim porosity:

Xaiv lub lim porosity uas haum rau hom khib nyiab thiab cov teeb meem uas koj xav kom ntsib. Finer porosity lim yuav ntxiab me me tab sis yuav txwv tsis pub airflow me ntsis.

4. Xaiv cov khoom siv ruaj khov:

Xaiv rau KF Lub Ntiv Nplhaib Nrog Lim ua los ntawm cov hlau tsis zoo los xyuas kom muaj kev tiv thaiv corrosion thiab hnav thiab tsim kua muag.

Yuav ua li casHloovKF Centering nplhaib nrog Lim

1. Disassemble lub tshuab nqus tsev twj txuas:

Disconnect lub tshuab nqus tsev twj los ntawm qhov txuas flange.

2. Tshem tawm lub qub KF Centering Ring Nrog Lim:

Ua tib zoo tshem tawm lub nplhaib qub qub thiab cov khoom lim.

3. Tshawb xyuas cov flanges thiab O-ring:

Ntxuav thiab tshuaj xyuas lub tshuab nqus tsev flange thiab txuas flange rau txhua qhov kev puas tsuaj lossis khib nyiab. Hloov O-ring yog tias nws puas lossis hnav.

4. Nruab lub KF Centering Ring tshiab nrog lim:

Muab lub nplhaib nruab nrab tshiab thiab cov khoom lim rau ntawm lub tshuab nqus tsev flange.

5. Reassemble lub tshuab nqus tsev twj txuas:

Ua tib zoo rov txuas lub flange txuas rau lub tshuab nqus tsev twj.

6. Leak kuaj qhov kev sib txuas:

Tshawb xyuas cov pa xau nyob ib puag ncig kev sib txuas siv txoj hauv kev kom pom cov pa xau.

Los ntawm ua raws li cov kauj ruam no thiab xaiv qhov tsim nyog KF Centering Ring Nrog Lim,

koj tuaj yeem tiv thaiv koj lub tshuab nqus tsev twj tso kua mis los ntawm cov khib nyiab thiab cov khoom me me, kom ntseeg tau nws

kev ua tau zoo tshaj plaws thiab kev ua haujlwm ntev.

FAQ txog KF Center Ring

1. Dab tsi yog KF Center Ring nrog Mesh Lim / Sintered Hlau Lim?

KF (Klein Flange) lub nplhaib nruab nrab nrog cov ntxaij lim dej lossis sintered hlau lim yog cov khoom siv tseem ceeb siv hauv lub tshuab nqus tsev, uas suav nrog ob qhov tseem ceeb: lub nplhaib nruab nrab thiab lub lim.

-

Lub nplhaib Centering:Qhov no yuav pab kho kom haum thiab muab ob lub flanges ntawm lub tshuab nqus tsev, kom ntseeg tau tias lub foob kaw ntom ntom. Nws feem ntau yog ua los ntawm cov roj hmab zoo li elastomer (feem ntau Viton lossis Buna-N), uas tuaj yeem hloov mus rau qhov tsis sib xws ntawm cov flange qhov chaw kom tiv thaiv kom tsis txhob muaj cua nkag mus rau hauv lub tshuab nqus tsev.

-

Mesh Filter / Sintered Hlau Lim:Qhov no yog muab tso rau hauv lub nplhaib centering. Nws lub hom phiaj yog lim tawm cov plua plav, cov khoom, lossis lwm yam khoom paug uas yuav cuam tshuam qhov zoo ntawm lub tshuab nqus tsev lossis cov txheej txheem ua hauv nws. Cov lim yuav yog ib qho yooj yim mesh (uas ntxiab cov khoom loj dua) los yog sintered hlau lim. Sintered hlau lim yog tsim los ntawm cov hlau me me uas ua kom sov kom txog thaum lawv sib koom ua ke, tsim kom muaj cov ntxeem tau zoo tab sis muaj zog lim uas tuaj yeem cuam tshuam cov khoom zoo heev.

KF lub nplhaib nruab nrab nrog lub mesh lossis sintered hlau lim yog li ua haujlwm rau ob lub hom phiaj hauv lub tshuab nqus tsev: kaw lub kaw lus kom tswj tau lub tshuab nqus tsev, thiab lim lub kaw lus kom tiv thaiv kev sib kis. Qhov no ua rau lawv qhov tseem ceeb rau cov ntawv thov uas xav tau lub tshuab nqus tsev huv si, xws li kev tsim khoom semiconductor, kev ua tshuaj lom neeg, kev ua zaub mov, tshuaj, thiab kev tshawb fawb tshawb fawb.

2. Cov ntxaij lim dej sib txawv li cas los ntawm sintered hlau lim hauv KF Center Ring?

Lub ntxaij lim dej yog cov hlau tsis muaj hlau uas ntes cov khoom loj thiab cov impurities. Lub sintered hlau lim yog ua los ntawm cov hmoov hlau uas tau raug compressed thiab sintered los ua ib tug ntxeem tau qauv. Nws yog tsim los tshem tawm cov khoom me me thiab impurities.

3. Dab tsi yog qhov txiaj ntsig ntawm kev siv lub mesh los yog sintered hlau lim hauv KF Center Ring?

Kev koom ua ke ntawm ib lub mesh los yog sintered hlau lim nyob rau hauv KF Centering Nplhaib muaj ntau yam txiaj ntsig, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas yuav tsum tau ua kom huv thiab tswj cov khoom hauv lub tshuab nqus tsev. Nov yog qee qhov txiaj ntsig tseem ceeb:

-

Txhim kho Particle Filtration:Ob lub ntxaij lim dej thiab sintered hlau tuaj yeem ntes cov plua plav, cov khoom, thiab lwm yam muaj peev xwm, yog li tiv thaiv lawv los ntawm kev nkag mus rau hauv lub tshuab nqus tsev. Qhov no yog qhov tseem ceeb rau kev tswj xyuas kev ncaj ncees thiab kev huv ntawm cov txheej txheem ua hauv qhov system.

-

High Temperature Resistance:Sintered hlau lim, tshwj xeeb tshaj yog, tuaj yeem tiv taus qhov kub thiab txias yam tsis tau poob lawv cov qauv kev ncaj ncees lossis pom muaj peev xwm. Qhov no ua rau lawv haum rau cov ntawv thov uas muaj qhov kub thiab txias.

-

Chemical Resistance:Ob lub mesh thiab sintered hlau lim feem ntau yog ua los ntawm cov ntaub ntawv uas tiv taus ntau yam tshuaj. Qhov no ua rau lawv zoo tagnrho rau kev siv tshuaj ua cov ntawv thov lossis hauv ib puag ncig uas lawv tuaj yeem raug rau ntau yam tshuaj.

-

Enhanced Durability:sintered hlau lim tau paub txog lawv cov kev ua haujlwm siab vim yog cov txheej txheem sintering, uas khi cov khoom hlau ua ke los tsim cov qauv zoo, tsis tau ntxeem tau. Qhov no tso cai rau lub neej ntev txawm nyob rau hauv kev ua haujlwm nyuaj.

-

Customizable Pore Loj:sintered hlau lim muab qhov zoo ntawm customizable pore qhov ntau thiab tsawg, tso cai rau kev tswj cov qib pom. Qhov no txhais tau tias lawv tuaj yeem raug kho rau cov ntawv thov uas xav tau tshwj xeeb particle loj cais tawm.

-

Kev tu yooj yim:Mesh thiab sintered hlau lim yog feem ntau yooj yim los ntxuav lossis hloov, ua kom lub tshuab nqus tsev tswj tau zoo dua.

-

Preservation ntawm Vacuum Integrity:Tej zaum qhov tseem ceeb tshaj plaws, kev siv lub nplhaib nruab nrab nrog cov lim dej sib xyaw ua ke pab tswj lub foob ntawm lub tshuab nqus tsev, khaws cia lub tshuab nqus tsev ruaj khov thaum tseem muab cov khoom pom. Qhov kev ua haujlwm dual no tuaj yeem pab txhim kho kev ua haujlwm thiab kev ntseeg tau.

Los ntawm kev muab ob qho tib si pom thiab kev sib khi, KF Lub Ntiv Nplhaib nrog cov ntxaij lim dej lossis sintered hlau lim tuaj yeem txhim kho qhov kev ua tau zoo thiab kev ntseeg siab ntawm lub tshuab nqus tsev, ua rau nws muaj txiaj ntsig zoo hauv ntau yam kev lag luam thiab kev siv.

4. Kuv yuav xaiv lub mesh los yog sintered hlau lim rau kuv KF Center Ring li cas?

Kev xaiv ntawm cov ntxaij lim dej los yog lub tshuab lim hlau sintered yuav nyob ntawm seb qhov kev xav tau tshwj xeeb ntawm koj lub tshuab nqus tsev, nrog rau qhov loj thiab hom khoom uas yuav tsum tau muab tshem tawm.

5. Puas tuaj yeem siv cov ntxaij lim dej lossis sintered hlau rov qab siv rau hauv KF Center Ring?

Yog lawm, feem ntau, cov ntxaij lim dej los yog cov hlau sintered tuaj yeem rov qab siv tau, tab sis nws yuav nyob ntawm seb cov xwm txheej tshwj xeeb ntawm lub tshuab nqus tsev thiab qhov kev sib kis.

6. Ntev npaum li cas kuv yuav tsum hloov cov ntxaij lim dej lossis sintered hlau hauv kuv KF Center Ring?

Kev hloov zaus yuav nyob ntawm seb cov xwm txheej ntawm lub tshuab nqus tsev, nrog rau theem ntawm kev sib kis thiab qhov loj ntawm cov khoom raug lim. Nws raug nquahu kom kuaj xyuas lub lim dej tsis tu ncua thiab hloov nws raws li xav tau.

7. Dab tsi yog qhov ntsuas kub siab tshaj plaws rau lub mesh lossis sintered hlau lim hauv KF Center Ring?

Qhov ntsuas kub siab tshaj plaws yuav txawv nyob ntawm qhov tshwj xeeb mesh lossis sintered hlau lim siv hauv KF Center Ring. Nws yog ib qho tseem ceeb uas yuav tau sab laj nrog cov chaw tsim khoom tshwj xeeb rau cov lim tshwj xeeb. Rau Sintered hlau lim nrog lub nplhaib nruab nrab, Max kub tuaj yeem ncav cuag 600 degrees.

8. Cov ntxaij lim dej lossis sintered hlau puas tuaj yeem raug ntxuav thiab rov siv dua hauv KF Center Ring?

Yog lawm, feem ntau, cov ntxaij lim dej lossis sintered hlau lim tuaj yeem raug ntxuav thiab rov qab siv dua, tab sis nws yuav nyob ntawm lub tshuab nqus tsev qhov tshwj xeeb thiab qhov kev sib kis.

9. Dab tsi yog qhov kev saib xyuas ntawm KF Center Ring nrog cov ntxaij lim dej lossis sintered hlau lim?

Kev saib xyuas yuav tsum nyob ntawm qhov tshwj xeeb mesh lossis sintered hlau lim siv hauv KF Center Ring. Nws raug nquahu kom sab laj cov chaw tsim khoom tshwj xeeb rau cov lim tshwj xeeb siv.

10. Puas muaj kev ceev faj tshwj xeeb uas yuav tsum tau ua thaum txhim kho cov ntxaij lim dej lossis sintered hlau lim hauv KF Center Ring?

Ua raws li cov chaw tsim khoom cov lus qhia thaum txhim kho cov ntxaij lim dej lossis sintered hlau lim hauv KF Center Ring yog qhov tseem ceeb. Nws yuav ua kom muaj kev txhim kho kom raug thiab tiv thaiv cov lim lossis lub tshuab nqus tsev puas.

Npaj txhij los ua cov kauj ruam tom ntej los nrhiav kev daws teeb meem rau koj cov kev xav tau? Saib tsis ntxiv! Ntawm HENGKO, peb pab pawg kws tshaj lij tau mob siab rau pab koj nrhiav qhov koj tab tom nrhiav. Tsuas yog xa email tuaj rau peb nrog Koj Qhov Xav Tau rau lub nplhaib nruab nrab ntawmka@hengko.comthiab peb yuav sib tham los tham txog koj cov kev xav tau tshwj xeeb thiab peb tuaj yeem pab tau li cas. Tsis txhob plam lub sijhawm no los ua haujlwm nrog qhov zoo tshaj plaws hauv kev lag luam, xa koj cov lus nug hnub no!