Sintered lim yog ib qho tseem ceeb ntawm cov txheej txheem kev lag luam.

Lawv yog cov hlau tseem ceeb uas tsim los ntawm kev sib xyaw cov hlau me me ua ke, los ntawm cov txheej txheem hu ua sintering,

ntawm qhov kub thiab txias hauv qab lub melting point. Cov qauv tshwj xeeb no ua rau lawv muaj ntau yam zoo:

* Siab porosity:

Lawv muaj ib feem pua ntawm qhov chaw khoob, tso cai rau cov kua dej dhau los thaum ua rau cov khoom tsis xav tau.

* Lub zog thiab durability:

Sintered lim muaj zog thiab tuaj yeem tiv taus qhov kub thiab txias.

* Versatility:

Lawv tuaj yeem tsim los ntawm ntau yam hlau thiab tuaj yeem sib txawv qhov pore kom haum rau ntau qhov kev xav tau pom.

Cov kev zoo no ua rau cov lim dej sintered tseem ceeb rau ntau yam kev lag luam. Lawv yog cov tseem ceeb siv nyob rau hauv:

* Kev ua tshuaj lom neeg:

Lim tawm catalysts, cais cov khoom xav tau los ntawm cov tshuaj tiv thaiv sib tov, thiab tshem tawm cov kab mob.

* Khoom noj khoom haus thiab dej haus:

Ua kua dej kom meej, tshem tawm cov kab mob, thiab lim tawm cov khoom tsis xav tau.

* Pharmaceuticals:

Sterilizing daws, lim tawm impurities, thiab tswj particle loj hauv cov tshuaj.

* Automotive:

Lim roj, lubricants, thiab hydraulic kua.

* Cua thiab roj pom:

Tshem tawm cov plua plav, cov khoom, thiab cov kab mob ntawm cov pa thiab cov pa.

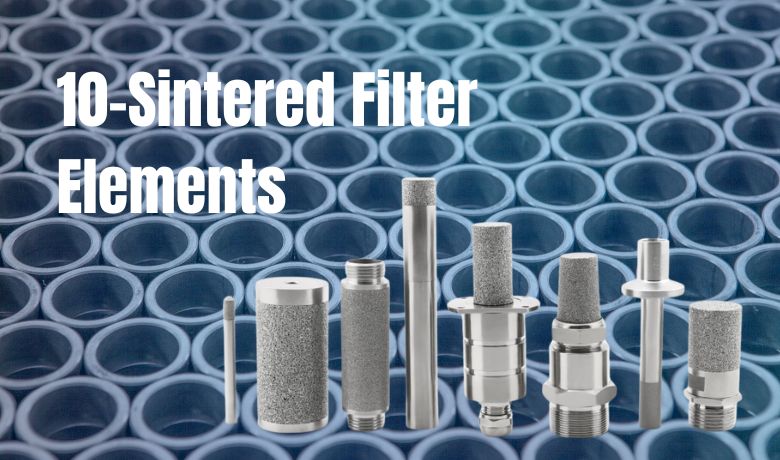

Tom qab ntawd raws li hauv qab no, kuv yuav pib qhia koj 10 sintered lim ntsiab nrov siv hauv khw.

1. Stainless Hlau Sintered Lim Elements

Stainless hlau sintered lim yog ntau yam thiab txhim khu kev qha hom lim xov xwm siv dav hauv kev lag luam roj.

thiab daim ntawv thov kua filtration. Lawv yog tsim los ntawm kev sib xyaw me me stainless hlau hais ua ke los ntawm sintering

txheej txheem ntawm qhov kub thiab txias, hauv qab lub melting point ntawm cov hlau. Cov txheej txheem sintering no tsim cov hlau tsis sib xws

qauv uas muaj ntau yam khoom tseem ceeb:

* Siab zog thiab durability:

Stainless hlau sintered lim tuaj yeem tiv taus qhov kub thiab txias, ua rau lawv tsim nyog rau kev xav tau kev lag luam ib puag ncig.

* Zoo heev corrosion kuj:

Stainless hlau yog ib txwm resistant rau corrosion los ntawm ntau yam tshuaj, ua rau lawv zoo tagnrho rau siv nrog hnyav kua.

* Siab porosity:

Sintered cov ntxaij lim dej muaj feem pua ntawm qhov chaw khoob hauv lawv cov qauv, tso cai rau cov kua dej thiab cov roj ntau ntau.

thaum zoo ntxiab hais loj dua qhov pore loj.

* Versatility:

Lawv tuaj yeem tsim nyob rau hauv ntau yam duab thiab qhov ntau thiab tsawg nrog ntau qhov kev ntsuas micron kom haum rau ntau hom kev xav tau pom.

* Yooj yim ntawm kev ntxuav:

Stainless hlau lim tuaj yeem rov qab ntxuav lossis ntxuav nrog cov kuab tshuaj, ua rau lawv rov siv tau rau lub sijhawm ntev.

Daim ntawv thov:

Cov khoom no ua rau cov hlau tsis muaj steel sintered lim tau xaiv rau ntau daim ntawv thov hauv kev lag luam roj thiab kua pom, suav nrog:

* Gas lim:

Tshem tawm cov plua plav, cov khoom, thiab cov pa paug los ntawm huab cua thiab roj ntws hauv ntau cov txheej txheem kev lag luam, suav nrog compressed cua pom,

natural gas filtration, thiab ntsuas cua pom.

* Kua filtration:

Lim tawm cov kab mob, kab mob, thiab lwm yam kab mob los ntawm cov kua siv hauv kev ua tshuaj, khoom noj thiab dej haus,

tshuaj, thiab kev kho dej.

* Roj thiab roj pom:

Tshem tawm cov impurities thiab cov kab mob los ntawm cov roj lubricating, hydraulic kua, thiab roj los tiv thaiv cov cuab yeej thiab xyuas kom muaj kev ua haujlwm zoo.

Ntxiv nrog rau cov kev siv dav dav no, stainless hlau sintered cov ntxaij lim dej kuj tau ua haujlwm hauv ntau cov txheej txheem tshwj xeeb hauv kev pom, suav nrog:

* Catalyst rov qab:Rov qab muaj txiaj ntsig catalysts los ntawm cov tshuaj tiv thaiv sib xyaw hauv cov txheej txheem tshuaj lom neeg.

* Sterilization:Sterilizing kev daws teeb meem thiab gasses hauv kev lag luam tshuaj thiab biotechnology.

* Emission tswj:Tshem tawm cov khoom me me thiab cov pa phem ntawm cov kwj deg kom ua raws li cov cai ntawm ib puag ncig.

2. Stainless Hlau Sintered Mesh Lim

Stainless hlau sintered mesh lim yog ib hom kev lag luam lim xov xwm dav siv hauv kev lag luam zaub mov thiab dej haus vim

lawv cov khoom tshwj xeeb. Lawv yog tsim los ntawm fusing txheej ntawm me me stainless hlau mesh ua ke los ntawm high-temperature

sintering txheej txheem, hauv qab lub melting point ntawm cov hlau. Cov txheej txheem no tsim cov qauv hlau nruj, ntxeem tau uas muaj ntau yam zoo:

Main nta:

* Siab zog thiab durability:

* Zoo heev corrosion kuj:

* Yooj yim ntawm kev ntxuav:

Cov khoom no ua rau cov hlau tsis muaj steel sintered mesh lim cov kev xaiv nrov rau ntau yam kev siv hauv cov zaub mov thiab dej haus pom, suav nrog:

Daim ntawv thov:

* Kev qhia meej ntawm cov kua:

* Pre-filtration rau daim nyias nyias:

* Kev lim dej:

* Pom cov syrups thiab roj:

* Cua thiab roj pom:

3. Bronze Sintered Lim

Bronze sintered lim yog lwm hom hlau lim xov xwm siv hauv kev lag luam. Lawv raug tsim los ntawm cov txheej txheem zoo sib xws

raws li stainless hlau lim, tab sis es tsis txhob stainless hlau hmoov, bronze alloy hmoov yog siv los ua cov khoom siv hauv paus. Ntawm no yog ib qho kev tawg ntawm lawv

Cov yam ntxwv thiab kev tsim khoom:

Main nta:

Yam ntxwv:

* Nqi-zoo:

2. Moulding:

3. Sintering:

4. Deburring thiab tiav:

Daim ntawv thov:

Vim lawv cov yam ntxwv, bronze sintered lim pom muaj kev siv hauv cov kua fais fab thiab hydraulic systems:

* Kev lim dej hydraulic:

* Lubrication system pom:

* Cua lim:

Thaum cov ntxaij lim dej bronze muab cov kev daws teeb meem zoo rau ntau lub zog siv dej thiab siv hydraulic, nws tseem ceeb heev rau

xav txog lawv cov kev txwv nyob rau hauv cov nqe lus ntawm corrosion kuj piv rau stainless hlau lim rau daim ntaub ntawv uas muaj hnyav tshuaj los yog ib puag ncig.

4. Sintered Polyethylene Lim:

Txheej txheem cej luam:

Nta thiab Cov txiaj ntsig:

* Cov tshuaj tiv thaiv siab rau cov kuab tshuaj organic thiab cov kua qaub.

* Lub teeb yuag thiab raug nqi.

* Biocompatible, ua rau lawv haum rau qee qhov kev siv tshuaj.

* Zoo rau huab cua thiab roj pom.

Daim ntawv thov

Siv hauv Pharmaceutical thiab Biotechnological Industries:

5. Sintered iav lim:

Cov khoom ntawm Sintered iav:

Nta:

* Cov tshuaj tiv thaiv zoo heev rau ntau yam tshuaj.

* Siab thermal stability, tso cai rau kev siv ntawm qhov kub thiab txias.

* Inert thiab tuaj yeem siv rau kev ua kom tsis muaj menyuam.

* High filtration efficiency rau cov khoom zoo.

Daim ntawv thov:

Cov ntawv thov zoo nyob rau hauv Laboratory thiab Environmental Testing:

6. Nickel-based Sintered Lim:

Kev sib xyaw thiab nta:

Muaj peev xwm kub-kub, ua rau lawv haum rau qhov xav tau ib puag ncig.

Zoo mechanical zog rau kev siv high-pressure.

Daim ntawv thov

Kev siv nyob rau hauv qhov kub thiab txias ib puag ncig:

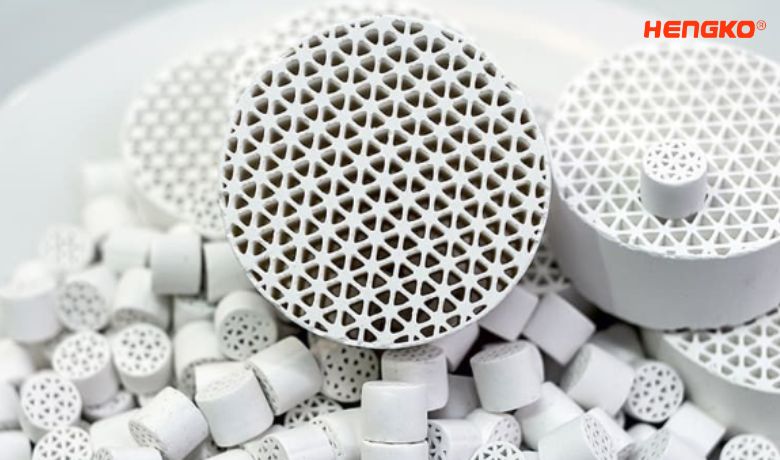

7. Sintered Ceramic Lim:

Ntsiab nta thiab Durability:

Daim ntawv thov

Daim ntawv thov hauv Hlau Casting thiab Cua Purification:

8. Titanium Sintered Lim:

Cov txiaj ntsig, nta, thiab cov khoom tiv thaiv:

Titanium-sintered lim muab ib qho kev sib xyaw ua ke ntawm lub zog siab, zoo heev corrosion kuj, thiab

Daim ntawv thov

Nyiam siv nyob rau hauv tshuaj ua thiab Marine Industries:

9. Sintered Silver Lim:

Unique Properties, Features, thiab Effectiveness:

Sintered silver filters yog qhov zoo tshaj plaws rau lawv cov khoom siv tshuaj tiv thaiv kab mob.

Daim ntawv thov:

Siv hauv Dej Purification thiab Antimicrobial Filtration:

Cov lim dej no yog qhov zoo tagnrho rau kev siv cov dej lim dej thiab cov ntawv thov uas xav tau

10. Sintered Activated Carbon Lim:

Composition, Nta, thiab Lim Peev Xwm:

Cov ntxaij lim dej no ua ke cov qauv hlau sintered nrog embedded activated carbon granules.

Daim ntawv thov hauv Gas Purification thiab Odor Control:

Sintered activated carbon lim tau ua haujlwm hauv huab cua thiab roj purification systems kom tshem tawm cov pa tsis zoo,

5- Yam Koj Yuav Tsum Saib Xyuas Xaiv Txoj CaiSintered lim

Xaiv qhov zoo tshaj plaws sintered lim rau koj daim ntawv thov kev lag luam yuav tsum tau ua tib zoo xav txog ntau yam:

1. Micron ntsuam xyuas:

Qhov no yog hais txog qhov loj ntawm cov khoom uas lub lim tuaj yeem ntxiab. Xaiv qhov ntsuas micron me dua li qhov koj xav tshem tawm.

2. Khoom siv:

Cov khoom siv lim dej yuav tsum sib haum nrog cov kua dej uas nws yuav raug rau. Stainless hlau yog ib qho kev xaiv nrov

rau nws cov corrosion kuj, tab sis lwm yam kev xaiv xws li tooj liab los yog npib tsib xee yuav haum nyob ntawm daim ntawv thov.

3. Kub thiab siab:

Lub lim yuav tsum tiv taus qhov kub thiab txias ntawm koj cov txheej txheem.

4. Flow tus nqi:

Lub lim yuav tsum tso kua dej txaus kom tau raws li koj cov txheej txheem xav tau thaum tswj xyuas kom zoo.

5. Kev tu thiab tu:

Xav txog seb nws yuav yooj yim npaum li cas los ntxuav thiab tswj cov lim. Backwashing lossis regeneration muaj peev xwm

ua qhov tseem ceeb rau qee qhov kev siv.

Los ntawm kev ua tib zoo ntsuas cov qauv no, koj tuaj yeem xaiv cov lim sintered uas ua kom zoo rau koj cov txheej txheem kev lag luam

thiab xyuas kom zoo, txhim khu kev qha pom.

Hu rau HENGKO

Yog tias koj xav tau cov lus qhia ntxaws ntxiv lossis xav tham txog koj cov kev xav tau tshwj xeeb pom,

Xa koj cov lus rau peb:

Post lub sij hawm: Apr-26-2024