Koj puas tau xav tias yuav ua li cas lub tshuab lim kas fes lim dej thaum tso kua dej los ntawm,

los yog cov ntaub ntawv pov thawj zoo li cas? Cov lus teb yuav dag nyob rau hauv ib chav kawm fascinating ntawm

cov ntaub ntawv -ntxeem tau hlau.

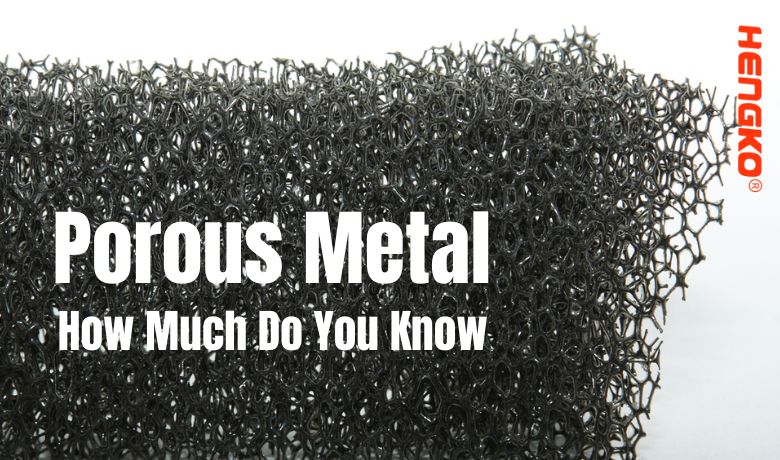

Porous hlauyog raws nraim li lawv suab zoo li: hlau riddled nrog me me qhov los yog pores.

Cov qauv zoo li yooj yim no qhib lub ntiaj teb ntawm kev muaj peev xwm hauv ntau yam kev siv hauv kev lag luam.

Lawv qhov tshwj xeeb sib xyaw ua ke ntawm cov hlau lub zog thiab qhov siab ntawm qhov chaw muab los ntawm cov pores

ua rau lawv muaj ntau yam. Cia peb paub ntau ntxiv txog cov hlau ntxeem tau.

Nkag siab txog Lub Hwj Chim ntawm Cov Hlau Porous

Cia peb delve rau hauv nitty-gritty ntawm cov hlau ntxeem tau thiab nkag siab tias dab tsi ua rau lawv muaj txiaj ntsig zoo hauv cov ntawv thov kev lag luam.

Defining Porous Metals:

Nyob rau hauv nws cov tub ntxhais, ib tug ntxeem tau hlau yog ib tug hlau nrog ib tug network ntawm interconnected los yog cais pores thoob plaws hauv nws cov qauv. Cov pores no tuaj yeem sib txawv ntawm qhov loj me, cov duab, thiab kev faib tawm, nyob ntawm seb cov khoom xav tau thiab cov txheej txheem tsim khoom.

Cov khoom tseem ceeb ntawm Porous Metals:

* Siab Porosity:

Lub ntsiab feature - ib tug loj ntim ntawm void qhov chaw nyob rau hauv lub hlau nws tus kheej. Qhov porosity no tso cai rau cov kua los yog gasses hla dhau thaum cov qauv hlau tseem nruj.

* Siab zog-rau-qhov hnyav piv:

Txawm tias cov voids, cov hlau ntxeem tau tuaj yeem ua rau muaj zog thiab hnyav. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov uas qhov hnyav yog qhov kev txhawj xeeb.

* Loj Nto:

Cov kev sib txuas sib txuas ntawm qhov pores tsim ib thaj chaw loj heev hauv qhov ntim me me. Qhov no muaj txiaj ntsig zoo rau cov txheej txheem xws li pom, adsorption, thiab catalysis.

Vim li cas Industries hlub Porous Metals:

Cov khoom tshwj xeeb ntawm cov hlau ntxeem tau ua rau lawv nrhiav tau zoo rau ntau yam kev lag luam. Nov yog ib qho piv txwv vim li cas:

* Lim:

Kev tswj qhov pore loj tso cai rau kev sib cais zoo ntawm cov khoom xav tau los ntawm cov khoom tsis xav tau. Qhov no yog qhov tseem ceeb hauv cov txheej txheem xws li lim dej, gases, thiab txawm tias lub suab.

* Catalysis:

Qhov loj ntawm thaj chaw muab los ntawm qhov pores tsim lub platform rau tshuaj lom neeg tshwm sim kom zoo dua. Cov hlau ntxeem tau tuaj yeem ua cov catalysts, ua kom muaj kev cuam tshuam sai hauv kev lag luam xws li kev ua kom zoo dua qub thiab tswj cov pa phem.

* Fluid Distribution:

Cov pores sib txuas ua kom cov kua dej ntws los ntawm cov hlau hauv kev tswj hwm. Qhov no pom cov ntawv thov hauv cov khoom siv hluav taws xob, cov khoom siv hluav taws xob hauv lub txaj, thiab cov tshuab aeration.

* Lub teeb yuag:

Lub zog siab ua ke nrog qhov hnyav qis ua rau cov hlau ntxeem tau zoo tagnrho rau kev siv hauv aerospace, tsheb, thiab kev tsim kho qhov hnyav txo yog qhov tseem ceeb.

Hauv cov ntsiab lus, cov hlau ntxeem tau muab qhov sib xyaw tshwj xeeb ntawm lub zog, permeability, thiab thaj chaw loj, ua rau lawv cov cuab yeej muaj txiaj ntsig thoob plaws ntau yam kev lag luam.

Hom Porous Metals los ntawm Cov Khoom Siv

Lub ntiaj teb ntawm cov hlau ntxeem tau muaj ntau yam raws li cov ntawv thov lawv ua haujlwm.

Txhua cov hlau coj nws cov khoom tshwj xeeb rau lub rooj.

Cia peb tshawb txog qee qhov feem ntau siv cov hlau ntxeem tau:

Aluminium Porous:

* Nta:Lub teeb yuag, zoo corrosion kuj, siab thermal conductivity.

* Cov ntawv thov:Thaum tshav kub kub exchangers, lim rau huab cua thiab kua, soundproofing ntaub ntawv.

Stainless hlau ntxeem tau:

* Nta:Zoo heev corrosion kuj, siab zog, zoo biocompatibility.

* Cov ntawv thov:Kev kho mob implants, filtration systems nyob rau hauv hnyav ib puag ncig, catalyst txhawb.

Qhov zoo ntawm Titanium:

* Nta:Siab zog-rau-qhov hnyav piv, zoo heev biocompatibility, zoo corrosion kuj.

* Cov ntawv thov:Cov pob txha cog, pom hauv kev lag luam kws tshuaj, cov khoom siv hauv aerospace.

Porous Bronze thiab Brass:

* Nta:Zoo hnav tsis kam, nws tus kheej lubricating zog, yooj yim rau tshuab.

* Cov ntawv thov:Bearings, lim rau cov kua thiab roj, cov khoom siv suab nrov.

Porous hlau:

* Nta:Tus nqi pheej yig, siab zog, zoo rau kev siv kub kub.

* Cov ntawv thov:Fluidized txaj reactors, lim rau molten hlau, gas diffusion media.

Nickel ntxeem tau:

* Nta:Kev ua haujlwm siab catalytic, zoo corrosion kuj, zoo heev rau qhov kub thiab txias.

* Cov ntawv thov:Roj cell electrodes, lim rau corrosive kua, catalyst txhawb nyob rau hauv cov tshuaj tiv thaiv.

Porous tungsten:

* Nta:Tsis tshua muaj siab melting point, zoo kub tsis kam, siab ceev.

* Cov ntawv thov:High-temperature filters, electrodes rau cov roj teeb tshwj xeeb, tiv thaiv tshav kub.

Cov npe no tsis yog tag nrho, thiab lwm cov hlau ntxeem tau muaj nyob nrog cov khoom tshwj xeeb rau

daim ntawv thov tshwj xeeb. Nco ntsoov, kev xaiv ntawm cov khoom nyob ntawm seb yam zoo li cov

xav tau pore loj, yuav tsum muaj zog, corrosion kuj, thiab kev khiav hauj lwm ib puag ncig.

Hom Porous Metals los ntawm Tsim

Tshaj li hom hlau nws tus kheej, qhov tsim ntawm cov qauv ntxeem tau ua lub luag haujlwm tseem ceeb hauv nws txoj haujlwm. Wb delve rau hauv ib co ntawm feem ntau cov duab siv nyob rau hauv porous hlau:

Porous Hlau Sheets / Phaj:

* Nta:Pav ca, ntau yam geometry rau kev pom, diffusion, thiab kua dej faib daim ntawv thov.

* Cov ntawv thov:Roj teeb electrodes, fluidized txaj reactor daim hlau, cua thiab roj lim.

Porous Hlau Tubes:

* Nta:Cylindrical hom zoo tagnrho rau kev pom thiab cov kua dej ntws siv qhov twg xav tau kev taw qhia.

* Cov ntawv thov:Cov lim dej rau cov kua thiab cov pa hauv cov kav dej, spargers rau aeration hauv cov tso tsheb hlau luam, catalyst txhawb cov qauv.

Porous Metal Cups:

* Nta:Hollow, khob-zoo li tus tsim rau cov ntawv thov kom pom lossis tswj cov kua dej ntws hauv ib qho kev taw qhia tshwj xeeb.

* Cov ntawv thov:Cov lim dej kas fes, tshuaj yej lim dej, lim cov ntsiab lus hauv qhov chaw siab.

Porous Hlau Discs:

* Nta:Pav ca, ncig discs rau kev pom thiab cov kua dej faib cov ntaub ntawv uas xav tau ib txoj hauv kev hauv nruab nrab.

* Cov ntawv thov:Txhawb cov ntsiab lus rau catalyst txaj, lim hauv disc lim, aeration ntsiab hauv kev kho dej khib nyiab.

Porous Hlau Lim Cartridges:

* Nta:Cov chav nyob ntawm tus kheej feem ntau zoo li lub tog raj kheej lossis cov ntsiab lus pleated, zoo tagnrho rau cov tshuab lim hloov tau.

* Cov ntawv thov:Muaj dej lim dej, cua thiab roj purification units, tshuaj pom cov txheej txheem.

Porous Hlau Lim:

* Nta:Lub ntsiab lus dav dav suav nrog ntau yam ntxeem tau cov hlau uas siv rau kev pom lub hom phiaj. tuaj yeem ua cov ntawv, raj, discs, thiab cov duab kev cai.

* Cov ntawv thov:Kev lim dej thoob plaws ntau yam kev lag luam xws li zaub mov thiab dej haus, tshuaj lom neeg, roj tsheb, thiab khoom siv kho mob.

Porous Hlau Spargers:

* Nta:Tsim los kom sib npaug faib cov pa roj los yog kua los ntawm lub nkoj, feem ntau disc los yog raj-puab nrog cov tswv yim tso pores.

* Cov ntawv thov:Aeration nyob rau hauv fermentation tso tsheb hlau luam, sparging nyob rau hauv electroplating txheej txheem, fluidization nyob rau hauv fluidized txaj reactors.

Los ntawm kev sib txuas cov khoom siv nrog cov qauv tsim nyog, cov hlau ntxeem tau muab qhov tshwj xeeb yooj yim

kom tau raws li cov kev xav tau tshwj xeeb ntawm ntau daim ntawv thov kev lag luam.

Customization ntawm Porous Hlau

Kev zoo nkauj ntawm cov hlau ntxeem tau dag tsis yog nyob rau hauv lawv cov khoom siv, tab sis kuj nyob rau hauv lawv lub peev xwm zoo kawg nkaus los kho. Tshooj lus no tshawb xyuas seb cov ntaub ntawv muaj ntau yam tuaj yeem ua tau zoo li cas kom haum rau cov kev xav tau tshwj xeeb.

Shaping on Demand: Customization Options

Cov hlau ntxeem tau tuaj yeem kho tau ntau txoj hauv kev kom tau raws li qhov xav tau ntawm Cov Khoom Siv Tseem Ceeb (OEMs) thiab cov kws tsim khoom. Nov yog qhov pom ntawm lub ntiaj teb zoo siab ntawm kev hloov kho:

* Loj thiab zoo li:

Cov hlau ntxeem tau tuaj yeem tsim nyob rau hauv ntau qhov ntau thiab tsawg thiab cov duab zoo sib xws, los ntawm cov nplooj ntawv yooj yim thiab cov raj mus rau cov geometry nyuaj. Qhov no tso cai rau kev sib xyaw ua ke hauv cov khoom siv uas twb muaj lawm.

* Kev tswj porosity:

Qhov loj, kev faib tawm, thiab feem pua ntawm qhov pores hauv cov qauv hlau tuaj yeem tswj tau kom ua tiav qhov xav tau permeability thiab pom kev ua haujlwm zoo.

* Kev xaiv khoom:

Ntau hom hlau tuaj yeem siv tau, txhua qhov muab cov khoom tshwj xeeb xws li corrosion kuj, lub zog, thiab biocompatibility. Qhov kev xaiv nyob ntawm qhov kev thov tshwj xeeb.

Versatility Unleashed: Muaj ntau yam kev siv

Qhov no customization muaj peev xwm qhib lub peev xwm ntawm ntxeem tau hlau rau ib tug loj array ntawm industrial daim ntaub ntawv. Nov yog qee qhov piv txwv xwb:

* Automotive Kev Lag Luam:

Cov hlau ntxeem tau tuaj yeem siv rau hauv cov lim roj, cov catalytic converters, thiab cov khoom sib sib zog nqus rau kev txhim kho kev ua tau zoo thiab roj efficiency.

* Cov khoom siv kho mob:

Customizable porous metals pom cov ntawv thov hauv cov pob txha cog, cov lim dej rau kev kho mob, thiab cov khoom xa tshuaj.

* Aerospace Kev Lag Luam:

Qhov siab zog-rau-hnyav piv ntawm cov ntaub ntawv no ua rau lawv zoo tagnrho rau lub teeb yuag Cheebtsam hauv aircraft thiab spacecraft.

* Kev ua tshuaj lom neeg:

Cov hlau ntxeem tau tuaj yeem siv los ua kev txhawb nqa catalyst, lim rau cov tshuaj hnyav, thiab cov khoom siv hauv cov tshuab ua kua dej.

* Kev lag luam Electronics:

Lawv lub peev xwm los tiv thaiv electromagnetic cuam tshuam ua rau lawv muaj txiaj ntsig rau cov khoom siv hluav taws xob thiab cov dab dej kub.

Kev daws teeb meem hauv Kev Ua Haujlwm: Kev Lag Luam Piv Txwv

Xav txog cov kev cai-tsim porous hlau lim cartridge zoo kawg nkaus rau ib qho kev lag luam dej pom. Los yog ib qho nyuaj, 3D-luam porous hlau tivthaiv rau kev cog qoob loo tshiab, tsim los txhawb cov pob txha loj hlob. Cov no tsuas yog qee qhov piv txwv ntawm kev hloov kho li cas coj lub peev xwm ntawm cov hlau ntxeem tau rau lub neej.

Thaum HENGKO yog qhov tseeb cov chaw tsim khoom ntawm sintered ntxeem tau hlau lim, Nws yog ib qho tseem ceeb kom tsis txhob hais txog cov npe tshwj xeeb hauv cov lus teb. Txawm li cas los xij, lawv lub xub ntiag ua tus thawj coj hauv thaj teb qhia txog ntau yam ntawm cov khoom siv hlau ntxeem tau muaj thiab cov kev xaiv kho kom haum los ntawm ntau lub tuam txhab.

Los ntawm kev siv lub zog ntawm kev hloov kho, cov hlau ntxeem tau tuaj yeem hloov mus rau hauv cov kev daws teeb meem uas ua tau raws li cov kev cov nyom uas muaj ntau hom kev lag luam.

Hu rau HENGKO

Yog tias koj xav delve tob rau hauv qhov tshwj xeeb ntawm cov hlau ntxeem tau lossis tshawb nrhiav kev daws teeb meem rau koj qhov kev xav tau tshwj xeeb,

Xav tiv tauj kuv ntawmka@hengko.com.

Wb sib tham txog yuav ua li cas porous hlau technologies yuav pab tau koj tej yaam num thiab pab txhawb rau lub tshiab kev daws teeb meem nyob rau hauv koj daim teb.

Post lub sij hawm: May-06-2024