Porous hlau discs, yam ntxwv los ntawm lawv interconnected pore qauv, tau tshwm sim raws li ib tug revolutionary khoom nrog ib tug dav spectrum ntawm kev siv. Cov discs, crafted los ntawm ntau yam hlau, muaj ib tug tshwj xeeb ua ke ntawm cov khoom uas ua rau lawv indispensable nyob rau hauv ntau yam industries. Lawv qhov tseem ceeb yog nyob rau hauv lawv lub peev xwm ua tau zoo hauv kev pom, kev faib dej, thiab roj diffusion, thaum tswj tau zoo kawg nkaus thiab ruaj khov nyob rau hauv huab cua.

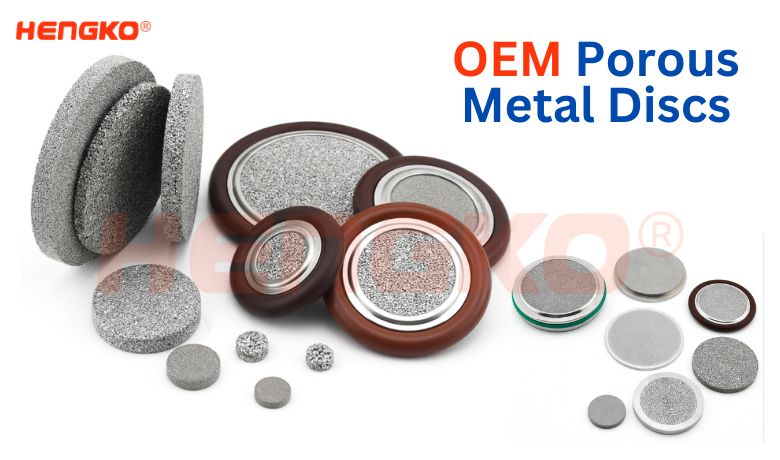

Porous Metal Discs: Ib Ntog rau hauv lawv cov versatility

Porous hlau discs yog tsim los ntawm ntau yam txuj ci, nrog rau sintering, etching, thiab electrospinning. Cov txheej txheem no tso cai rau kev tswj xyuas meej ntawm qhov pore loj thiab kev faib tawm, ua rau kev hloov kho ntawm cov khoom siv kom haum rau cov ntawv thov tshwj xeeb. Lub porosity, xws li ntawm 30% mus rau 90%, txiav txim siab lub disc permeability, cuam tshuam nws lub peev xwm los lim lossis faib cov kua thiab roj.

Kev Tshawb Fawb Sib Piv: Cov Hlau Nqus Nroj Tsuag nrog cov khoom siv niaj hnub

Txhawm rau kom txaus siab rau qhov tseem ceeb ntawm cov hlau ntxeem tau, cia peb muab piv nrog cov khoom siv ib txwm siv hauv ntau yam lag luam.

Lim

Nyob rau hauv lub realm ntawm pom, ntxeem tau hlau discs sawv tawm rau lawv superior efficiency thiab durability. Lawv cov qauv pore intricate ntxiab cov kab mob nrog qhov zoo tshaj plaws, txawm tias nyob rau theem submicron. Tsis tas li ntawd, lawv cov kev tiv thaiv corrosion thiab kub kub ua rau lawv zoo tagnrho rau qhov chaw hnyav. Piv nrog rau cov ntawv lim dej los yog cov ntaub ntawv polymer, cov hlau ntxeem tau muaj qhov ua tau ntev dua thiab txo cov nqi tu.

Kev faib ua kua

Porous hlau discs ua tau zoo nyob rau hauv cov ntaub ntawv faib cov kua dej, kom ntseeg tau tias tsis sib xws thiab tiv thaiv channeling. Lawv tswj qhov pore geometry tso cai rau kev tswj hwm tus nqi ntws thiab kev faib tawm siab. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov hauv kev ua tshuaj, tshuaj, thiab aerospace, qhov chaw xa dej zoo ib yam yog qhov tseem ceeb. Cov khoom siv niaj hnub xws li cov phaj perforated lossis hlau meshes feem ntau tawm tsam kom ua tiav tib theem ntawm qhov tseeb thiab sib xws.

Gas Diffusion

Porous hlau discs ua lub luag haujlwm tseem ceeb hauv kev siv roj diffusion, ua kom muaj txiaj ntsig zoo sib pauv roj thiab txhawb cov tshuaj lom neeg. Lawv cov porosity siab thiab kev sib txuas ntawm pore qauv txo qhov kev tawm tsam tsis zoo, tso cai rau cov pa roj permeate los ntawm cov disc sai. Qhov no ua rau lawv cov khoom tseem ceeb hauv cov roj hlwb, roj teeb, thiab cov roj sensors, qhov twg roj diffusion efficiency yog qhov tseem ceeb. Cov khoom siv niaj hnub xws li ntxeem tau ceramics lossis cov yeeb yaj kiab polymer feem ntau pom cov pa roj permeabilities tsawg dua thiab tsis muaj kev ruaj ntseg nyob rau hauv kev kub siab lossis kub.

Xaus: Porous Hlau Discs - Cov Khoom Siv Yav Tom Ntej

Porous hlau discstau ruaj khov tsim lawv tus kheej ua cov khoom tseem ceeb, hloov pauv ntau yam kev lag luam nrog lawv cov khoom sib xyaw tshwj xeeb. Lawv lub peev xwm pom zoo tshaj plaws, tshwj xeeb tshaj tawm cov kua dej, thiab cov pa roj diffusion ua rau lawv tseem ceeb rau ntau yam kev siv. Raws li kev siv thev naus laus zis thiab cov ntawv thov tshiab tau tshwm sim, cov hlau ntxeem tau tau npaj los ua lub luag haujlwm tseem ceeb dua hauv kev tsim lub neej yav tom ntej ntawm engineering thiab kev tsim khoom.

1. Nkag siab txog Porous Metal Discs

1.1 Kev piav qhia ntawm Porous Hlau Discs

Porous hlau discs yog ib chav kawm ntawm cov khoom siv hluav taws xob tsim los ntawm lawv cov kev sib txuas ntawm cov pores. Cov pores no, xws li qhov loj me ntawm micrometers mus rau millimeters, tso cai rau kev tswj cov dej thiab cov pa roj thaum lim tawm cov pa paug. Porous hlau discs feem ntau yog tsim los ntawm cov hlau xws li stainless hlau, bronze, thiab npib tsib xee, muab kev sib xyaw ua ke ntawm lub zog, durability, thiab corrosion kuj.

1.2 Kev tsim cov txheej txheem ntawm Porous Hlau Discs

Ntau cov tswv yim yog ua haujlwm los tsim cov hlau ntxeem tau, txhua tus muaj nws tus kheej zoo thiab kev txwv. Cov txheej txheem kev tsim khoom muaj xws li:

1. Sintering: Sintering yuav tsum compressing hlau hmoov rau hauv cov duab uas xav tau thiab ces cua sov nws mus rau qhov kub thiab txias hauv qab lub melting point. Cov txheej txheem no tso cai rau cov khoom siv hlau sib txuas ua ke, tsim kom muaj cov qauv ntxeem tau.

2. Etching: Etching yuav xaiv tshem tawm cov khoom los ntawm cov khoom hlau substrate los tsim cov pores. Txoj kev no muaj kev tswj xyuas qhov pore loj thiab kev faib tawm.

3. Electrospinning: Electrospinning siv hluav taws xob los kos cov fibers zoo los ntawm cov tshuaj polymer. Cov fibers no tuaj yeem sintered los yog sib koom ua ke los tsim cov hlau ntxeem tau.

1.3 Qhov zoo ntawm Porous Hlau Discs

Porous hlau discsmuab ntau yam zoo dua li cov ntaub ntawv ib txwm muaj xws li ntawv, polymer, lossis cov lim dej ceramic:

1. Superior Filtration Efficiency: Porous hlau discs tuaj yeem lim cov pa paug ntawm qhov me me, mus rau qib submicron.

3. Reusability thiab Sustainability: Porous hlau discs tuaj yeem ntxuav thiab rov qab siv ntau zaus, txo kev cuam tshuam ib puag ncig.

4. Versatility thiab Customization: Porous hlau discs tuaj yeem kho raws li qhov pore loj, porosity, thiab cov khoom muaj pes tsawg leeg kom haum rau cov kev siv tshwj xeeb.

5. Biocompatibility: Qee cov porous hlau discs yog biocompatible, ua rau lawv haum rau kev kho mob thiab tshuaj siv.

2. Muaj pes tsawg hom Porous Hlau Discs?

Porous hlau discs raug cais raws li lawv qhov pore loj, porosity, thiab cov khoom muaj pes tsawg leeg. Nov yog qee yam ntawm ntau hom:

1. Sintered Porous Hlau Discs:

Cov discs no yog tsim los ntawm sintering hlau hmoov ntawm qhov kub thiab txias.

Lub resulting discs muaj ib tug uniform pore loj thiab tis, ua rau lawv

zoo tagnrho rau daim ntaub ntawv filtration.

2. Etched Porous Hlau Discs:

Cov discs no yog tsim los ntawm etching ib tug qauv rau hauv ib tug khoom hlau ntawv.

Txoj kev no tso cai rau kev tswj xyuas qhov pore loj thiab cov duab,

ua rau lawv haum rau daim ntaub ntawv uas yuav tsum tau high precision.

3. Electrospun Porous Hlau Discs:

Cov discs no yog tsim los ntawm electrospinning ib tug daws ntawm hlau nanoparticles mus rau ib tug substrate.

Lub resulting discs muaj ib tug heev porosity thiab ib tug random pore qauv, ua rau lawv haum

rau daim ntawv thov qhov twg gas diffusion tseem ceeb.

4. Graded Porous Hlau Discs:

Cov discs muaj gradient ntawm pore loj los ntawm qhov chaw mus rau sab hauv.

Qhov gradient no tso cai rau kev pom zoo dua, vim tias cov khoom loj dua raug kaw

nyob rau sab nrauv thiab cov khoom me me yog dai rau ntawm sab hauv.

5. Multilayer Porous Hlau Discs:

Cov discs no yog tsim los ntawm txheej txheej ob peb discs sib txawv pore loj ua ke.

Qhov no tso cai rau cov creation ntawm complex filtration systems uas yuav tshem tawm ib tug dav

ntau yam kab mob.

6. Wicking Porous Hlau Discs:

Cov discs no yog tsim los wick kua rau hauv lub pores.

Qhov no ua rau lawv muaj txiaj ntsig rau cov ntawv thov uas nws tseem ceeb rau

faib cov kua dej sib npaug, xws li hauv cov roj hlwb thiab cov roj teeb.

7. Porous Hlau Discs rau Biomedical Applications:

Cov discs no yog tsim los ntawm cov khoom siv biocompatible, xws li titanium thiab stainless hlau.

Lawv yog siv nyob rau hauv ntau yam kev kho mob daim ntawv thov, xws li cov pob txha implants thiab tshuaj xa cov tshuab.

3. Kev sib piv nrog cov tsoos Disc Lim

1. Kev ua tau zoo

Porous hlau discs muab cov txiaj ntsig zoo ntawm cov khoom siv ib txwm muaj nyob rau hauv cov nqe lus ntawm durability, efficiency, thiab functionality.

| Feature | Porous Hlau Discs | Cov khoom siv niaj hnub |

|---|---|---|

| Durability | Siab | Tsawg |

| Kev ua tau zoo | Siab | Nruab nrab |

| Kev ua haujlwm | Siab | Nruab nrab |

Porous hlau discs yog qhov ruaj khov heev thiab tuaj yeem tiv taus qhov hnyav, qhov kub thiab txias. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov uas cov ntaub ntawv ib txwm ua sai sai lossis poob. Tsis tas li ntawd, cov hlau ntxeem tau muaj qhov ua tau zoo tshaj plaws ntawm kev pom, kev faib dej, thiab roj diffusion. Lawv cov qauv pore intricate tso cai rau kev tswj xyuas meej ntawm cov nqi ntws thiab kev faib tawm siab, ua rau kev txhim kho kev ua haujlwm hauv ntau yam kev siv.

2. Tus nqi zoo

Txawm hais tias cov hlau ntxeem tau tuaj yeem muaj tus nqi pib dua piv rau cov khoom siv ib txwm muaj, lawv cov nqi siv tau ntev yog feem ntau zoo dua. Lawv durability thiab reusability txo qhov kev xav tau ntawm kev hloov ntau zaus, thiab lawv cov kev xav tau kev saib xyuas qis dua ntxiv txo cov nuj nqis ua haujlwm.

| Feature | Porous Hlau Discs | Cov khoom siv niaj hnub |

|---|---|---|

| Tus nqi pib | Nruab nrab | Tsawg |

| Tus nqi kho mob | Tsawg | Nruab nrab |

| Txuag mus sij hawm ntev | Siab | Nruab nrab |

Sij hawm dhau mus, kev txuag nyiaj los ntawm kev txo qis kev saib xyuas thiab hloov cov nqi tuaj yeem ua rau ntau dua qhov kev nqis peev ntau dua hauv cov hlau ntxeem tau. Qhov no ua rau lawv muaj txiaj ntsig zoo rau cov ntawv thov uas muaj kev ntseeg siab ntev thiab kev ua haujlwm tseem ceeb.

3. Kev cuam tshuam ib puag ncig

Porous hlau discs muaj ntau yam zoo ib puag ncig ntawm cov khoom siv tsoos. Lawv durability thiab reusability txo cov khoom pov tseg, thiab lawv lub peev xwm los rov ua dua ntxiv txo qis lawv qhov chaw ib puag ncig. Tsis tas li ntawd, cov hlau ntxeem tau siv tau los tsim cov khoom lag luam ruaj khov, xws li roj hlwb thiab roj teeb, uas ua rau muaj kev nyab xeeb rau yav tom ntej.

| Feature | Porous Hlau Discs | Cov khoom siv niaj hnub |

|---|---|---|

| Sustainability | Siab | Tsawg |

Porous hlau discs yog ib qho kev xaiv cov khoom siv ruaj khov uas tuaj yeem pab txo kev cuam tshuam ib puag ncig thiab txhawb kev lag luam ntau dua. Lawv durability, reusability, thiab recyclability ua rau lawv ib puag ncig lub luag hauj lwm xaiv rau ntau yam kev siv.

Hauv kev xaus, porous hlau discs muab kev sib xyaw ua ke ntawm kev ua tau zoo, kev ua tau zoo, thiab kev ruaj ntseg ib puag ncig. Lawv superior durability, efficiency, thiab functionality ua rau lawv ib tug zoo tagnrho xaiv rau cov thov kev thov, thaum lawv mus sij hawm ntev kev txuag nqi thiab ib puag ncig cov txiaj ntsig ua rau lawv muaj kev lag luam ruaj khov. Raws li kev siv thev naus laus zis thiab cov ntawv thov tshiab tau tshwm sim, cov hlau ntxeem tau tau npaj los ua lub luag haujlwm tseem ceeb hauv kev tsim lub neej yav tom ntej ntawm engineering thiab kev tsim khoom.

4. Kev lag luam-Specific Applications thiab kev sib piv

Aerospace

Porous hlau discs ua lub luag haujlwm tseem ceeb hauv kev siv aerospace, tshwj xeeb tshaj yog nyob rau hauv cov tshuab pom thiab cov khoom siv cav. Lawv muaj peev xwm tiv taus qhov kub thiab txias, siab, thiab kev vibrations ua rau lawv zoo tagnrho rau cov cheeb tsam xav tau no.

Lim Systems

Porous hlau discs yog siv nyob rau hauv ntau yam filtration systems thoob plaws hauv lub dav hlau, xws li:

-

Fuel Filtration: Lawv tshem tawm cov khoom paug tawm ntawm lub dav hlau roj, kom ntseeg tau tias kev ua haujlwm zoo ntawm cov cav thiab lwm yam tseem ceeb.

-

Hydraulic Filtration: Lawv lim cov kua dej hydraulic, tiv thaiv kev hnav thiab tsim kua muag ntawm cov tshuab hydraulic thiab xyuas kom meej tswj cov khoom siv dav hlau.

-

Cua Lim: Lawv lim cua nkag mus rau hauv chav tsev thiab avionics, tswj kom huv thiab nyab xeeb rau cov neeg coob thiab cov neeg caij tsheb.

Cav Cheebtsam

Porous hlau discs kuj siv nyob rau hauv ntau yam cav Cheebtsam, xws li:

-

Combustor Liners: Lawv muab qhov ntxeem tau ntawm cov roj combustion, txhim kho kev ua haujlwm thiab txo qis emissions.

-

Thaum tshav kub kub Shields: Lawv tiv thaiv cov khoom rhiab los ntawm huab cua kub thiab thermal shock.

-

Flow Distributors: Lawv xyuas kom muaj kev faib tawm ntawm cov kua thiab roj, ua kom lub cav ua haujlwm zoo.

Automotive

Porous hlau discs nrhiav kev siv dav hauv kev lag luam tsheb, feem ntau hauv cov tshuab pa thiab lim.

Exhaust Systems

-

Catalytic Converters: Porous hlau discs ua lub substrate rau catalytic converters, txo cov teeb meem emissions los ntawm lub tsheb pa gases. Lawv muab thaj chaw siab rau cov tshuaj tiv thaiv catalytic, zoo hloov cov pa phem rau hauv cov khoom tsis zoo.

-

Mufflers: Lawv txhim kho lub suab nrov txo hauv mufflers, txo qis lub suab tsim los ntawm cov pa tawm. Lawv cov qauv ntxeem tau zoo absorbs thiab dissipates suab tsis.

Lim

-

Cua Lim: Porous hlau discs lim cua nkag mus rau hauv lub cav, tiv thaiv kev sib kis ntawm cov khoom rhiab thiab ua kom lub cav ua haujlwm zoo.

-

Roj Lim: Lawv lim cov roj cav, tshem tawm cov kab mob thiab ua kom cov roj lubrication zoo ntawm lub cav.

Kev ua tshuaj lom neeg

Porous hlau discs ua lub luag haujlwm tseem ceeb hauv kev ua tshuaj lom neeg, tshwj xeeb hauv cov txheej txheem catalysis thiab kev sib cais.

Catalysis

-

Catalyst Supports: Porous hlau discs muab thaj chaw siab rau catalysts, ua kom muaj cov tshuaj tiv thaiv zoo. Lawv txhawb nqa kev faib tawm ntawm cov khoom catalyst thiab txhim kho kev hloov pauv loj ntawm cov reactants thiab catalysts.

-

Fixed-Bed Reactors: Lawv ua haujlwm raws li cov khoom ntim hauv lub txaj ruaj khov reactors, pab tswj kev sib cuag ntawm cov reactants thiab catalysts. Lawv cov qauv pore niaj hnub ua kom pom kev txaus thiab cov tshuaj tiv thaiv zoo.

Cov txheej txheem sib cais

-

Kev lim dej: Cov hlau nplaum nplaum yog siv rau hauv cov tshuab lim kom tshem tawm impurities los ntawm ntau yam khoom siv tshuaj. Lawv tswj qhov pore loj tso cai rau kev xaiv cais cov khib nyiab los ntawm cov kua.

-

Membrane Separation: Lawv yog siv rau hauv cov txheej txheem membrane sib cais, xws li roj diffusion thiab pervaporation. Lawv cov qauv ntxeem tau tso cai rau kev xaiv cais cov pa roj lossis cov kua dej raws li lawv cov khoom molecular.

Cov cuab yeej kho mob

Porous hlau discs tau txais qhov tseem ceeb hauv kev siv cov cuab yeej siv kho mob, tshwj xeeb tshaj yog nyob rau hauv cov khoom cog thiab pom cov tshuab.

Kev cog hniav

-

Pob txha implants: Porous hlau discs yog siv rau hauv cov pob txha implants, xws li orthopedic implants thiab kho hniav implants. Lawv cov qauv ntxeem tau txhawb nqa cov pob txha ingrowth thiab osseointegration, ua kom muaj kev ruaj ntseg ntev thiab ua haujlwm.

-

Tissue Engineering Scaffolds: Lawv ua haujlwm ua haujlwm rau cov ntaub so ntswg engineering, muab kev txhawb nqa rau kev loj hlob ntawm tes thiab tsim cov ntaub so ntswg. Lawv cov qauv ntxeem tau tso cai rau cell infiltration thiab nutrient diffusion, txhawb kev tsim cov ntaub so ntswg.

Lim Systems

-

Kev lim ntshav: Porous hlau discs yog siv nyob rau hauv cov ntshav filtration systems, xws li hemodialysis lim. Lawv tswj qhov pore loj tso cai rau kev xaiv tshem tawm impurities los ntawm cov hlab ntsha thaum khaws cov ntshav tseem ceeb.

-

Kev xa tshuaj: Lawv tau muab tso rau hauv kev xa tshuaj, xws li stents thiab cog. Lawv cov qauv ntxeem tau tso cai rau kev tso tawm cov tshuaj, muab kev kho mob hauv zos rau cov mob tshwj xeeb.

Nta ntawm Sintered Porous Hlau Discs

| Feature | Tus nqi |

|---|---|

| Khoom siv | Stainless hlau, tooj liab, npib tsib xee |

| Txoj kev tsim khoom | Sintering |

| Pore Loj | Micrometer mus millimeter |

| Porosity | 30% txog 90% |

| Qhov zoo | High durability, efficiency, thiab functionality; Reusability; Biocompatibility (rau qee yam khoom) |

| Qhov tsis zoo | Tus nqi pib siab dua piv rau cov khoom siv tsoos |

Sintered ntxeem tau hlau discs tau dhau los ua neeg nyiam hauv kev lag luam vim lawv cov khoom tshwj xeeb thiab qhov zoo. Lawv yog tsim los ntawm sintering hlau hmoov ntawm qhov kub thiab txias, uas tsim ib tug ntxeem tau qauv nrog ib tug uniform pore loj thiab tis. Cov qauv no ua rau lawv zoo tagnrho rau ntau yam kev siv, suav nrog:

* Kev lim dej: Sintered ntxeem tau hlau discs tuaj yeem siv los lim ntau cov kua dej, suav nrog kua, roj, thiab slurries. Lawv muaj txiaj ntsig zoo ntawm kev tshem tawm cov kab mob ntawm cov kua dej no, ua rau lawv zoo tagnrho rau kev siv hauv cov txheej txheem kev lag luam uas xav tau qib siab purity.

* Cov dej faib tawm: Sintered porous hlau discs tuaj yeem siv los faib cov kua dej sib npaug thoob plaws ib qho chaw. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov xws li roj hlwb thiab cov roj teeb, qhov uas nws yog ib qho tseem ceeb rau kev faib cov kua dej sib npaug kom ua tau zoo tshaj plaws.

* Kev hloov tshav kub: Sintered ntxeem tau hlau discs tuaj yeem siv los hloov cov cua sov ntawm ib qho chaw mus rau lwm qhov. Lawv ua tau zoo ntawm kev ua cua sov, ua rau lawv zoo tagnrho rau kev siv xws li cov khoom siv hluav taws xob thiab cov dab dej kub.

Ntxiv nrog rau lawv cov khoom ua haujlwm, sintered ntxeem tau hlau discs kuj muaj ntau yam zoo dua cov ntaub ntawv ib txwm siv, xws li:

* Kev ua haujlwm siab: Sintered ntxeem tau hlau discs yog qhov ruaj khov thiab tuaj yeem tiv taus ib puag ncig hnyav. Lawv tiv taus corrosion, yaig, thiab hnav thiab tsim kua muag.

* Reusability: Sintered porous hlau discs tuaj yeem rov qab siv tau ntau zaus, uas ua rau lawv muaj txiaj ntsig zoo.

* Biocompatibility (rau tej yam ntaub ntawv): Qee cov sintered ntxeem tau hlau discs yog tsim los ntawm biocompatible ntaub ntawv, xws li titanium thiab stainless hlau. Qhov no ua rau lawv zoo tagnrho rau siv rau hauv kev kho mob cog thiab khoom siv.

Qhov tsuas yog qhov tsis zoo ntawm sintered ntxeem tau hlau discs yog lawv cov nqi pib dua piv rau cov khoom siv ib txwm muaj. Txawm li cas los xij, lawv cov kev txuag nyiaj mus sij hawm ntev, vim lawv rov siv dua thiab siv tau ntev, tuaj yeem cuam tshuam tus nqi pib no.

Zuag qhia tag nrho, sintered ntxeem tau hlau discs yog ntau yam khoom siv thiab muaj txiaj ntsig uas tuaj yeem siv rau ntau yam kev lag luam. Lawv cov khoom tshwj xeeb thiab qhov zoo ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas xav tau kev ua haujlwm siab, ua haujlwm tau zoo, thiab ua haujlwm.

Case Studies thiab Real-World Piv txwv

Nov yog qee cov ntaub ntawv ntxaws ntxaws qhia txog kev ua tau zoo ntawm cov hlau ntxeem tau hauv cov ntawv thov tshwj xeeb, nrog rau kev sib piv nrog cov xwm txheej uas cov ntaub ntawv ib txwm siv tau zoo sib xws:

Case Study 1: Fuel Cell Filtration

Teeb meem: Hauv cov roj hlwb, cov kab mob hauv cov pa roj tuaj yeem txhaws cov electrodes thiab txo kev ua haujlwm. Cov ntawv lim ntawv feem ntau siv los tshem tawm cov kab mob no, tab sis lawv tuaj yeem ua rau txhaws sai thiab yuav tsum tau hloov ntau zaus.

Kev daws: Porous hlau discs tuaj yeem siv los lim cov roj hauv cov roj hlwb. Lawv cov porosity siab thiab tswj qhov pore loj tso cai rau lawv kom tshem tawm cov kab mob tsis zoo yam tsis muaj qhov txo qis ntawm cov pa. Tsis tas li ntawd, cov hlau ntxeem tau muaj qhov ruaj khov thiab tuaj yeem tiv taus qhov hnyav ntawm cov roj cell.

Cov txiaj ntsig: Kev siv cov porous hlau discs hauv cov roj hlwb tau ua rau muaj kev txhim kho tseem ceeb hauv kev ua haujlwm thiab txo tus nqi kho. Nyob rau hauv ib txoj kev tshawb no, kev siv cov porous hlau discs nce roj cell efficiency los ntawm 10% thiab txo nqi txij nkawm los ntawm 50%.

Kev sib piv: Muab piv rau cov ntawv lim dej ib txwm siv, cov hlau ntxeem tau muaj ntau qhov zoo. Lawv muaj zog dua, ua haujlwm zoo dua, thiab yuav tsum tau hloov tsis tu ncua. Qhov no ua rau lawv muaj txiaj ntsig zoo dua rau kev lim roj ntawm tes.

Case Study 2: Exhaust System Mufflers

Teeb meem: Cov tsoos tso pa tawm mufflers feem ntau siv fiberglass lossis ceramic wool ua cov khoom siv suab nrov. Txawm li cas los xij, cov ntaub ntawv no tuaj yeem degrade dhau sijhawm thiab ua haujlwm tsawg dua. Tsis tas li ntawd, lawv tuaj yeem ua rau muaj hluav taws kub.

Kev daws: Porous hlau discs tuaj yeem siv los ua cov khoom siv suab nrov hauv cov pa tawm mufflers. Lawv cov qauv ntxeem tau zoo absorbs thiab dissipates suab tsis. Tsis tas li ntawd, cov hlau ntxeem tau muaj qhov ruaj khov thiab tuaj yeem tiv taus qhov kub thiab txias ntawm qhov tso pa tawm.

Cov txiaj ntsig: Kev siv cov porous hlau discs hauv cov pa tawm mufflers tau ua rau txo qis hauv cov suab nrov. Nyob rau hauv ib txoj kev tshawb no, kev siv cov porous hlau discs txo cov suab nrov emissions mus txog 10 dB.

Kev sib piv: Muab piv rau cov khoom siv suab nrov, cov hlau ntxeem tau muaj ntau qhov zoo. Lawv muaj zog dua, ua haujlwm zoo dua ntawm kev txo cov suab nrov emissions, thiab ua rau muaj kev phom sij tsawg dua. Qhov no ua rau lawv xav tau kev daws teeb meem ntau dua rau cov pa tawm mufflers.

Case Study 3: Blood Filtration in Hemodialysis

Teeb meem: Hauv hemodialysis, ntshav tau dhau los ntawm lub lim kom tshem tawm cov impurities. Cov lim dej lim dej feem ntau siv cellulose membranes ua cov khoom siv lim dej. Txawm li cas los xij, cellulose daim nyias nyias tuaj yeem ua rau kis kab mob thiab tuaj yeem nyuaj los ntxuav.

Kev daws: Porous hlau discs tuaj yeem siv los ua cov khoom siv lim dej hauv cov lim dej hemodialysis. Lawv tswj qhov pore loj tso cai rau lawv xaiv tshem tawm impurities ntawm cov ntshav thaum khaws cov ntshav tseem ceeb. Tsis tas li ntawd, cov hlau ntxeem tau muaj qhov ruaj khov thiab tuaj yeem ntxuav tau yooj yim.

Cov txiaj ntsig: Kev siv cov porous hlau discs hauv cov lim dej hemodialysis tau ua rau muaj kev txhim kho tseem ceeb hauv kev kho mob lim ntshav. Hauv ib txoj kev tshawb fawb, kev siv cov porous hlau discs txo cov impurities hauv cov ntshav mus txog 50%.

Kev sib piv: Muab piv rau cov khoom siv cellulose ib txwm muaj, cov hlau ntxeem tau muaj ntau qhov zoo. Lawv muaj zog dua, zoo dua ntawm kev tshem tawm impurities, thiab tuaj yeem ntxuav tau yooj yim. Qhov no ua rau lawv qhov kev xav tau ntau dua rau cov lim dej hemodialysis.

Cov ntaub ntawv tshawb fawb no qhia txog kev ua tau zoo ntawm cov hlau ntxeem tau hauv ntau yam kev siv. Lawv cov khoom tshwj xeeb thiab qhov zoo ua rau lawv muaj txiaj ntsig zoo rau ntau yam kev lag luam thiab kev siv kho mob.

Kuv vam tias cov ntaub ntawv no yuav pab tau. Thov qhia rau kuv paub yog tias koj muaj lus nug ntxiv.

Recap ntawm Cov Kev Tshawb Fawb Tseem Ceeb los ntawm Kev Tshawb Fawb Sib Piv

Peb txoj kev tshawb nrhiav rau hauv lub ntiaj teb ntawm cov hlau ntxeem tau tau nthuav tawm ntau qhov kev nkag siab tseem ceeb. Feem ntau, porous hlau discs muaj qhov tshwj xeeb zoo dua li cov ntaub ntawv ib txwm muaj nyob rau hauv ntau qhov kev lag luam vim lawv cov kev ua haujlwm zoo, kev ua haujlwm zoo, thiab kev ua haujlwm. Nyob rau hauv cov nqe lus ntawm kev ua tau zoo, cov discs sawv tawm nyob rau hauv ib puag ncig nyuaj, muab lub neej ntev dua thiab zoo dua tiv thaiv rau huab cua. Tus nqi-zoo yog lwm qhov chaw uas cov hlau ntxeem tau ci ntsa iab, muab kev txuag mus sij hawm ntev txawm tias muaj feem ntau dua cov nqi pib. Tsis tas li ntawd, lawv cov kev cuam tshuam ib puag ncig yog qhov tsis txaus ntseeg tsawg dua, ua kom zoo nrog qhov kev thov loj hlob rau kev coj ua lag luam ruaj khov.

Kev xav zaum kawg ntawm lub luag haujlwm ntawm Porous Hlau Discs hauv Kev Siv Khoom

Porous hlau discs tsis yog cov khoom siv xwb; lawv yog revolutionizing ntsiab nyob rau hauv industrial daim ntaub ntawv. Los ntawm aerospace mus rau cov cuab yeej kho mob, cov discs tau teeb tsa cov qauv tshiab rau kev ua tau zoo thiab kev ntseeg tau. Lawv adaptability thiab efficiency ua rau lawv zoo tagnrho rau ib tug ntau yam ntawm daim ntawv thov, taw qhia ib tug tseem ceeb hloov nyob rau hauv yuav ua li cas industries mus rau kev xaiv cov khoom thiab tsim. Raws li kev siv thev naus laus zis, peb tuaj yeem cia siab tias yuav muaj kev sib koom ua ke ntau dua ntawm cov hlau ntxeem tau rau hauv cov ntawv thov tshiab thiab tshiab, ntxiv dag zog rau lawv qhov tseem ceeb hauv kev lag luam toj roob hauv pes.

Koj puas muaj kev xav txog yav tom ntej daim ntawv thov ntawm porous hlau discs? Koj puas tau ntsib qee qhov kev sib tw tshwj xeeb lossis kev ua tiav hauv kev siv lawv hauv koj qhov kev lag luam?

Tej zaum koj muaj lus nug txog lawv cov khoom, kev tsim khoom, lossis kev siv tshwj xeeb?

Kuv xav kom koj qhia koj cov dab neeg, lus nug, thiab kev nkag siab rau peb.

Thov hu rau ntawm email ntawmka@hengko.com.

Koj cov tswv yim tsis yog txais tos xwb; Nws yog ib qho tseem ceeb rau kev nthuav dav peb cov kev sib tham thiab ua kom peb txoj kev paub tob tob

hais txog cov khoom siv ntau yam thiab tseem ceeb hauv kev lag luam niaj hnub no.

Post lub sij hawm: Nov-17-2023