Cov xov, qhov sib txawv ntawm cov spirals pom ntawm bolts, screws, thiab hauv cov txiv ntoo, yog qhov nyuaj dua li lawv tshwm sim. Lawv sib txawv hauv kev tsim, qhov loj me, thiab kev ua haujlwm, tsim txoj hauv kev sib xyaw ua ke hauv txhua yam los ntawm cov tshuab yooj yim mus rau qib siab engineering. Nyob rau hauv cov ntaub ntawv no, peb delve rau hauv lub hauv paus ntawm xov tsim, tshawb txog lub hauv paus ntsiab lus uas txawv ib tug xov los ntawm lwm tus. Los ntawm poj niam txiv neej ntawm threads mus rau lawv tes, thiab los ntawm lawv lub suab mus rau lawv txoj kab uas hla, peb nthuav tawm cov ntsiab lus tseem ceeb uas ua rau cov xov yog qhov tseem ceeb tab sis feem ntau overlooked marvel ntawm engineering.

Txheeb xyuas cov ntsiab lus raws li hauv qab no thaum peb nthuav tawm lub ntiaj teb tsis sib xws ntawm cov xov, muab koj lub hauv paus kev nkag siab qhov tseem ceeb rau ob qho tib si xav paub tshiab thiab cov kws tshaj lij.

Qee cov ntsiab lus tseem ceeb ntawm Xov

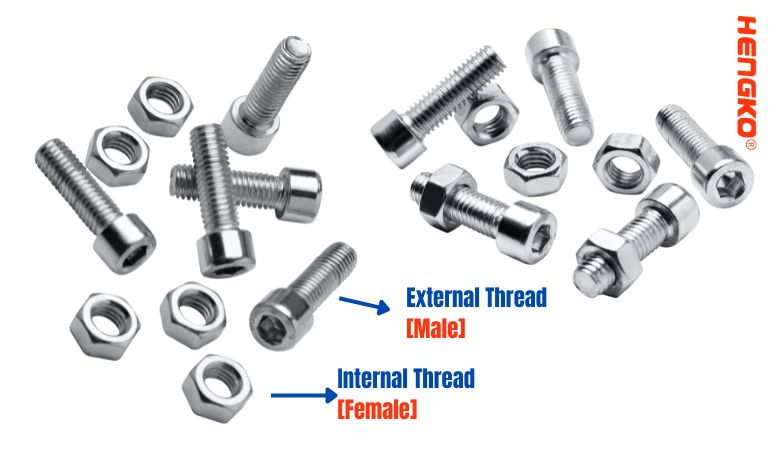

Kev siv cov ntsiab lus ntawm poj niam txiv neej tuaj yeem ua rau muaj kev phom sij tsis zoo thiab ua rau muaj kab lis kev cai ntawm kev cais tawm. Los ntawm kev siv cov ntsiab lus nruab nrab zoo li "sab nraud" thiab "internal" xov, peb tuaj yeem ua tau ntau dua thiab tsis txhob xav tsis thoob.

* Qhov tseeb:Qhov kev sib piv ua txhaum ntxiv thaum xav txog cov ntawv tsis yog binary xov thiab daim ntawv thov.

Nws yog ib qho tseem ceeb uas yuav tsum tau ua kom raug thiab suav nrog cov lus qhia thiab.

* Lwm txoj kev:Muaj cov ntsiab lus tseeb thiab tsim tau zoo rau cov yam ntxwv ntawm xov:

* Sab nraud threads:Xov nyob rau sab nraud ntawm ib feem.

* Internal threads:Threads nyob rau hauv ib feem.

* Loj txoj kab uas hla:Qhov loj tshaj txoj kab uas hla ntawm cov xov.

* Me diam:Qhov tsawg tshaj plaws txoj kab uas hla ntawm cov xov.

* Suab:Qhov kev ncua deb ntawm ob lub ntsiab lus sib thooj ntawm cov xov uas nyob ib sab.

Kev siv cov ntsiab lus no muab cov ntaub ntawv raug thiab tsis pom tseeb yam tsis muaj kev vam khom rau cov txiaj ntsig zoo sib xws.

Cov xov yog siv nyob rau hauv lim cov rooj sib txoos

Sintered lim tau dav siv nyob rau hauv ntau yam kev lag luam rau cov hom phiaj pom. Lawv yog tsim los ntawm kev sib txuas cov hmoov hlau ua ke los ntawm kev kho cua sov hu ua sintering. Qhov no tsim cov qauv muaj zog, ntxeem tau uas tuaj yeem lim tawm cov khoom los ntawm cov kua lossis cov pa roj.

Cov xov yog feem ntau siv hauv cov lim lim los txuas cov khoom sib txawv ua ke. Nov yog qee cov piv txwv tshwj xeeb ntawm yuav ua li cas threads siv nyob rau hauv sintered lim los ua ke:

* Lim cartridge kawg hau:

Ntau cov sintered lim cartridges muaj threaded kawg lub kaus mom uas tso cai rau lawv yuav tsum tau screwed rau hauv lim vaj tse.

Qhov no tsim kom muaj kev ruaj ntseg foob thiab tiv thaiv cov xau.

* Lim cov vaj tsev sib txuas:

Lim cov vaj tsev feem ntau muaj cov chaw nres nkoj uas tso cai rau lawv txuas nrog cov kav dej lossis lwm yam khoom siv.

Qhov no tso cai rau yooj yim installation thiab tshem tawm cov lim los ua ke.

* Pre-filters:

Qee lub rooj sib tham lim siv cov lim dej ua ntej kom tshem tawm cov khoom loj dua ua ntej lawv ncav cuag cov lim sintered.

Cov lim dej ua ntej no tuaj yeem ntsia tau rau hauv qhov chaw siv xov.

* Drainage ports:

Qee lub tsev lim dej muaj cov qhov dej ntws tawm uas tso cai rau tshem tawm cov kua dej los yog cov pa roj.

Qhov tshwj xeeb ntawm cov xov uas siv hauv cov lim sib dhos yuav nyob ntawm daim ntawv thov thiab qhov loj ntawm lub lim. Cov xov ntau hom muaj xws li NPT, BSP, thiab Metric.

Ntxiv rau cov piv txwv saum toj no, cov xov kuj tseem siv tau rau lwm lub hom phiaj hauv sintered lim cov rooj sib txoos, xws li:

* Txuas cov sensors lossis ntsuas ntsuas

* Mounting brackets

* Kev ruaj ntseg cov khoom siv sab hauv

Zuag qhia tag nrho, threads ua lub luag haujlwm tseem ceeb hauv kev ua kom zoo thiab ua haujlwm ntawm sintered lim cov rooj sib txoos.

Thaum kawg, kev xaiv ntawm terminology yog nyob ntawm koj.

Txawm li cas los xij, kuv xav kom koj xav txog qhov muaj feem cuam tshuam ntawm kev siv cov lus ntawm poj niam txiv neej thiab cov txiaj ntsig ntawm kev siv ntau qhov nruab nrab thiab suav nrog lwm txoj hauv kev.

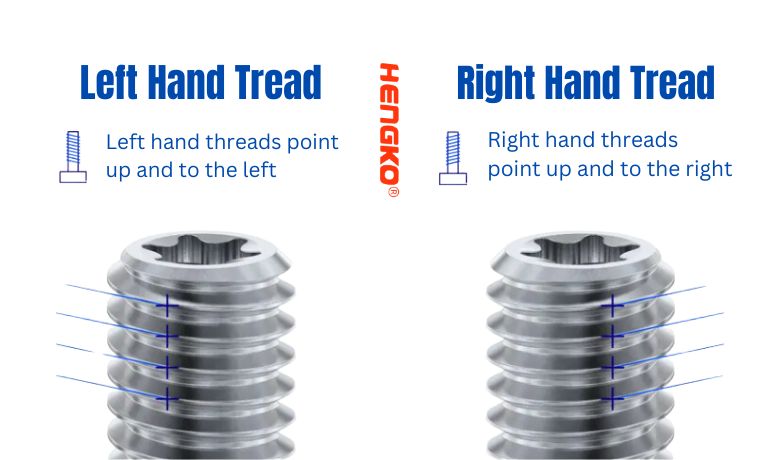

Handedness ntawm Xov

Yog vim li cas txoj cai threads ntau dua?

* Tsis muaj qhov laj thawj tseem ceeb hauv keeb kwm, tab sis qee qhov kev xav qhia tias nws tuaj yeem yog vim qhov kev tsis ncaj ncees ntawm tib neeg feem ntau yog sab tes xis, ua kom yooj yim rau kev nruj thiab xoob txoj cai xov nrog lawv txhais tes tseem ceeb.

* Txoj cai-tes threads kuj zoo li yuav ua rau nws tus kheej nruj thaum raug kev sib hloov quab yuam nyob rau hauv tib txoj kev raws li nruj (xws li, ib tug ntsia liaj qhov rooj ntawm lub spinning log).

Daim ntawv thov ntawm sab laug tes threads:

Raws li koj tau hais, cov xov sab laug feem ntau yog siv nyob rau hauv cov xwm txheej uas loosening vim kev co los yog kev sib hloov rog yog ib qho kev txhawj xeeb,

xws li: Lawv kuj tau siv rau hauv cov cuab yeej tshwj xeeb thiab cov cuab yeej siv qhov kev sib txawv ntawm kev sib hloov yog xav tau rau kev ua haujlwm.

* Lub raj mis roj: txhawm rau tiv thaiv kev sib tsoo qhib vim yog sab nraud.

* Cov tsheb kauj vab pedal: ntawm sab laug kom tiv thaiv lawv los ntawm kev xoob vim yog lub log pem hauv ntej tig.

* Kev cuam tshuam haum: Txhawm rau tsim kom nruj dua, ruaj ntseg haum uas tiv thaiv kev sib tsoo.

Kev txheeb xyuas cov threadedness:

* Qee lub sij hawm cov xov kev taw qhia yog cim ncaj qha rau ntawm lub fastener (piv txwv li, "LH" rau sab laug tes).

* Kev soj ntsuam lub kaum sab xis ntawm cov xov los ntawm sab tuaj yeem nthuav qhia cov kev taw qhia:

1. Txoj cai-tes threads nqes mus rau sab xis (zoo li tus ntsia hlau nce toj).

2. Sab laug tes threads nqes mus rau sab laug.

Qhov tseem ceeb ntawm kev siv tes ua hauv cov lim dej sintered thiab kev siv ntau.

Handedness, xa mus rau cov kev taw qhia ntawm xov rotation (clockwise los yog counter-clockwise), yog qhov tseem ceeb heev nyob rau hauv sintered lim daim ntaub ntawv rau ob peb lub laj thawj:

Sealing thiab Tiv thaiv Leak:

* Tightening thiab Loosening: Kev tuav kom zoo ua kom cov khoom nruj kom ruaj ntseg thaum tig mus rau hauv qhov kev xav tau thiab loosen yooj yim thaum xav tau. Cov xov tsis sib xws tuaj yeem ua rau muaj kev nruj dua, ua rau lub lim dej lossis vaj tsev puas tsuaj, lossis ua kom tsis tiav, ua rau cov xau.

* Galling thiab Seizing: Cov kev taw qhia xov tsis raug tuaj yeem tsim kev sib txhuam thiab kev sib tsoo, ua rau cov khoom nyuaj lossis tsis tuaj yeem sib cais. Qhov no tuaj yeem muaj teeb meem tshwj xeeb thaum kho lossis hloov lim.

Standardization thiab Compatibility:

- Interchangeability: Standardized xov handedness tso cai rau hloov tau yooj yim ntawm lim ntsiab los yog vaj tse nrog rau qhov chaw, tsis hais cov chaw tsim tshuaj paus. Qhov no yooj yim txij nkawm thiab txo cov nqi.

- Kev Tswj Xyuas Kev Lag Luam: Ntau qhov kev lag luam muaj cov kev cai tshwj xeeb hais txog kev xa xov hauv cov kua dej rau kev nyab xeeb thiab kev ua haujlwm. Kev siv cov xov tsis ua raws cai tuaj yeem ua txhaum txoj cai thiab ua rau muaj kev nyab xeeb.

Common Usages thiab Handedness:

- Filter Cartridge End Caps: Feem ntau siv txoj cai-tes threads (clockwise kom nruj) kom ruaj ntseg txuas rau lim vaj tse.

- Filter Housing Connections: Feem ntau ua raws li cov qauv kev lag luam, uas feem ntau qhia txoj cai xov rau cov yeeb nkab txuas.

- Pre-filters: Tej zaum yuav siv txoj cai los yog sab laug-tes threads nyob ntawm seb tus qauv tsim thiab npaj cov dej ntws.

- Cov Chaw Nres Nkoj: Feem ntau muaj txoj hlua khi rau qhov yooj yim qhib thiab kaw kom ntws cov kua dej.

Vam tias cov ntaub ntawv no tuaj yeem pab koj kom nkag siab cov ntsiab lus ntawm kev siv xov tooj!

Xov Design

Ob qho tib si sib luag thiab tapered threads ua lub luag haujlwm tseem ceeb hauv ntau daim ntawv thov, txhua tus muaj lawv tus kheej qhov zoo thiab kev siv. Txhawm rau ntxiv qee qhov tob rau koj qhov kev piav qhia, ntawm no yog qee cov ntsiab lus koj yuav xav txog:

1. Sealing Mechanisms:

* Parallel Xov:

Lawv feem ntau vam khom sab nraud xws li gaskets lossis O-rings rau kev sib txuas cov ntaub ntawv pov thawj.

Qhov no tso cai rau rov sib dhos thiab disassembly yam tsis muaj kev puas tsuaj rau cov xov.

* Tapered Xov:

Lawv tsim kom nruj, kev sib txuas ntawm tus kheej vim yog kev ua plees ua yi thaum lawv raug ntsia hlau.

Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov siab xws li cov kav dej thiab fittings.

Txawm li cas los xij, over-tightening tuaj yeem ua rau cov xov puas lossis ua rau lawv nyuaj rau tshem tawm.

2. Cov Qauv Txheej Txheem:

* Parallel Xov:

Cov no suav nrog cov qauv xws li Unified Thread Standard (UTS) thiab Metric ISO threads.

Lawv muaj nyob rau hauv daim ntawv thov dav dav xws li bolts, screws, thiab txiv ntseej.

* Tapered Xov:

National Pipe Thread (NPT) thiab British Standard Pipe Thread (BSPT)

yog dav siv nyob rau hauv cov kav dej thiab kua fais fab.

Daim ntawv thov:

* Parallel Threads: Siv nyob rau hauv rooj tog rooj tog, electronics, machinery, thiab ntau yam kev siv uas nquag disassembly thiab huv si seals yuav tsum tau.

* Tapered Threads: Zoo tagnrho rau cov kav dej, hydraulics, pneumatic systems, thiab txhua daim ntawv thov uas yuav tsum tau muaj kev sib txuas ntawm cov ntaub ntawv pov thawj los yog kev co.

Cov ntawv sau ntxiv:

* Qee cov qauv xov zoo li BSPP (British Standard Pipe Parallel) muab cov ntaub ntawv sib txuas nrog lub nplhaib sib khi rau kev sib txuas cov ntaub ntawv pov thawj.

* Xov suab (qhov deb ntawm cov xov) thiab xov qhov tob kuj ua lub luag haujlwm tseem ceeb hauv xov lub zog thiab kev ua haujlwm.

Qhov cuam tshuam ntawm txhua txoj xov tsim hom hauv sintered hlau lim.

Thaum xov tsim nws tus kheej tsis yog los ntawm cov lim hom, nws ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm thiab kev ua haujlwm ntawm sintered hlau lim cov rooj sib txoos. Nov yog yuav ua li cas txawv xov tsim cuam tshuam sintered hlau lim:

Common Thread Designs:

* NPT (National Pipe Thread): Siv dav hauv North America rau kev siv cov kav dej dav dav. Muab cov sealing zoo thiab yog yooj yim muaj.

* BSP (British Standard Pipe): Muaj nyob hauv Europe thiab Asia, zoo ib yam li NPT tab sis muaj qhov sib txawv me ntsis. Qhov tseem ceeb rau kev sib haum xeeb rau kev haum.

* Metric Threads: Standardized ntiaj teb no, muab dav xov suab xaiv rau cov kev xav tau tshwj xeeb.

* Lwm Cov Xov Xwm Tshwj Xeeb: Nyob ntawm daim ntawv thov, cov xov xov tshwj xeeb tsim xws li SAE (Society of Automotive Engineers) lossis JIS (Japanese Industrial Standards) yuav raug siv.

Qhov cuam tshuam ntawm thread Design:

* Kev sib khi thiab kev tiv thaiv tsis zoo: cov xov tsim tsim kom muaj kev sib txuas nruj, tiv thaiv kom tsis txhob xau thiab tswj cov lim dej kom zoo. Cov xov tsis sib haum tuaj yeem ua rau cov dej xau, cuam tshuam kev ua haujlwm thiab ua rau muaj kev nyab xeeb.

* Sib dhos thiab Disassembly: Cov xov sib txawv tsim muaj qhov sib txawv yooj yim ntawm kev sib dhos thiab disassembly. Cov yam ntxwv xws li xov suab thiab lubrication yuav tsum tau txiav txim siab rau kev saib xyuas zoo.

* Standardization thiab Compatibility: Standardized threads zoo li NPT los yog Metric kom compatibility nrog cov qauv lim vaj tse thiab piping systems. Kev siv cov xov tsis zoo tuaj yeem tsim teeb meem kev sib raug zoo thiab cuam tshuam kev hloov pauv.

* Lub zog thiab lub zog tuav: Xov tsim muaj kev cuam tshuam lub zog thiab muaj peev xwm los tswj lub siab hauv cov lim sib dhos. Cov ntawv thov kev siv hluav taws xob siab yuav xav tau cov xov tshwj xeeb nrog kev sib sib zog nqus rau kev xa khoom zoo dua.

Xaiv Txoj Cai Xov Tsim:

* Daim ntawv thov yuav tsum tau: xav txog yam xws li kev khiav hauj lwm siab, kub, kua compatibility, thiab xav tau los ua ke / disassembly zaus.

* Cov Qauv Kev Lag Luam: Ua raws li cov qauv kev lag luam thiab cov kev cai rau koj cheeb tsam tshwj xeeb lossis daim ntawv thov.

* Compatibility: Xyuas kom seamless compatibility nrog lim vaj tse, piping systems, thiab tej zaum yuav hloov qhov chaw.

* Kev Siv Yooj Yim: Sib npaug qhov xav tau rau lub foob ruaj ntseg nrog kev yooj yim ntawm kev saib xyuas thiab muaj peev xwm hloov pauv yav tom ntej.

Nco ntsoov, thaum xov tsim tsis txuas ncaj qha rau hom sintered hlau lim, nws yog ib qho tseem ceeb rau tag nrho cov kev ua tau zoo thiab kev ncaj ncees ntawm lub lim los ua ke. Xaiv cov xov zoo tsim raws li koj qhov kev thov tshwj xeeb thiab xav txog kev sab laj nrog tus kws tshaj lij pom kev rau kev taw qhia.

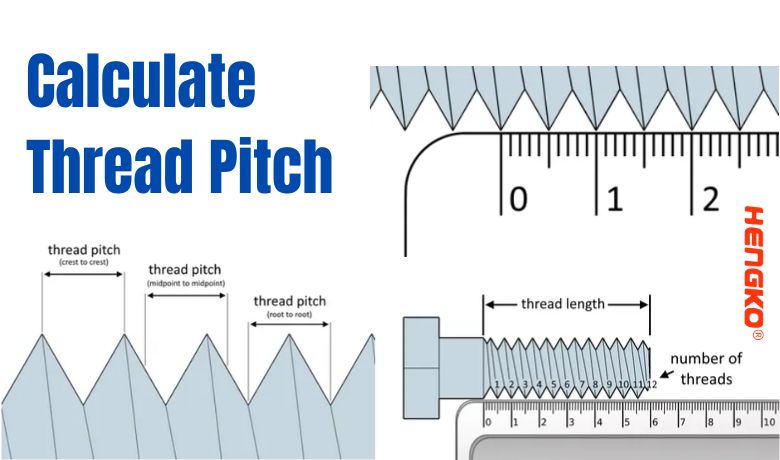

Pitch thiab TPI

* Pitch: Ntsuas nyob rau hauv millimeters, nws yog qhov kev ncua deb ntawm ib tug xov crest mus rau tom ntej.

* TPI (Threads Per Inch): Siv rau cov xov tooj ntiv tes, qhia cov xov tooj ntawm ib nti ntawm qhov ntev.

Kev sib raug zoo ntawm Pitch thiab TPI:

* Lawv yeej tseem ceeb ntsuas tib yam (xov ceev) tab sis nyob rau hauv txawv units thiab ntsuas tshuab.

1. TPI yog qhov sib txuam ntawm lub suab: TPI = 1 / Pitch (mm)

2. Hloov ntawm lawv yog ncaj nraim rau pem hauv ntej:Hloov TPI rau pitch: Pitch (mm) = 1 / TPI

Hloov suab rau TPI: TPI = 1 / Pitch (mm)

Qhov txawv tseem ceeb:

* Ntsuas Chav: Pitch siv millimeters (metric system), thaum TPI siv threads ib nti (imperial system).

* Daim ntawv thov: Pitch yog siv rau metric fasteners, thaum TPI yog siv rau nti-raws li fasteners.

Nkag siab xov ceev:

* Ob lub suab thiab TPI qhia koj li cas nruj nreem ntim cov xov ntawm lub fastener.

* Lub suab qis lossis siab dua TPI txhais tau tias ntau cov xov hauv ib chav tsev ntev, ua rau cov xov zoo dua.

* Finer threads feem ntau muab:

1. Muaj zog tiv thaiv kom xoob vim kev co los yog torque.

2. Txhim kho lub peev xwm sealing thaum siv nrog cov fittings tsim nyog.

3. Tsawg kev puas tsuaj rau mating threads thaum sib dhos thiab disassembly

Txawm li cas los xij, cov xov zoo dua kuj tseem tuaj yeem:

* Ua kom muaj kev cuam tshuam ntau dua rau kev hla xov lossis stripping yog tias tsis ua raws li qhov zoo.

* Yuav tsum muaj zog ntxiv kom nruj thiab xoob.

Xaiv txoj cai xov ceev:

* Cov ntawv thov tshwj xeeb thiab nws cov kev xav tau txiav txim siab lub suab zoo lossis TPI.

* Cov yam ntxwv xws li lub zog, kev vibration tsis kam, sealing xav tau, thiab yooj yim ntawm kev sib dhos / disassembly yuav tsum raug txiav txim siab.

* Kev sab laj cov qauv tsim nyog thiab cov txheej txheem engineering yog qhov tseem ceeb rau kev xaiv txoj xov zoo rau koj cov kev xav tau tshwj xeeb.

Txoj kab uas hla

Cov xov muaj peb qhov tseem ceeb diameters:

* Loj Loj: Qhov loj tshaj txoj kab uas hla ntawm xov, ntsuas ntawm crests.

* Me Diameter: Qhov me me txoj kab uas hla, ntsuas ntawm cov hauv paus hniav.

* Pitch Diameter: Ib txoj kab uas hla theoretical ntawm qhov loj thiab me diameters.

Nkag siab txhua txoj kab uas hla:

* Qhov Loj Loj: Qhov no yog qhov tseem ceeb rau kev ua kom muaj kev sib haum xeeb ntawm cov mating threads (piv txwv li, ntsia liaj qhov rooj thiab cov txiv ntoo). Bolts thiab ceev nrog tib txoj kab uas hla loj yuav haum ua ke, tsis hais lub suab los yog xov daim ntawv (parallel los yog tapered).

* Cov kab me me: Qhov no cuam tshuam rau lub zog ntawm kev sib koom tes xov. Ib txoj kab me me loj dua qhia cov khoom siv ntau dua thiab muaj peev xwm muaj zog dua.

* Pitch Diameter: Qhov no yog txoj kab uas hla uas cov xov profile muaj cov khoom sib npaug ntawm cov khoom saum toj thiab hauv qab. Nws ua lub luag haujlwm tseem ceeb hauv kev suav xov lub zog thiab lwm yam khoom siv hluav taws xob.

Kev sib raug zoo ntawm Diameter:

* Cov diameters muaj feem cuam tshuam los ntawm xov profile thiab suab. Cov qauv xov sib txawv (xws li metric ISO, Unified National Coarse) muaj kev sib raug zoo ntawm cov kab no.

* Pitch txoj kab uas hla tuaj yeem suav nrog siv cov qauv raws li qhov loj thiab me diameters, lossis pom hauv cov lus siv rau cov qauv xov tshwj xeeb.

Qhov tseem ceeb ntawm kev nkag siab txoj kab uas hla:

* Paub txog txoj kab uas hla loj yog qhov tseem ceeb rau xaiv cov fasteners sib xws.

* Cov kab me me cuam tshuam lub zog thiab tej zaum yuav cuam tshuam rau cov ntawv thov tshwj xeeb nrog kev thauj khoom siab.

* Pitch txoj kab uas hla yog qhov tseem ceeb rau kev suav engineering thiab nkag siab cov khoom xov.

Lus Cim Ntxiv:

* Qee cov qauv xov txhais cov kab uas hla ntxiv xws li "hauv paus txoj kab uas hla" rau cov hom phiaj tshwj xeeb.

* Xov kam rau ua specifications txiav txim siab hloov pauv hauv txhua txoj kab uas hla rau kev ua haujlwm kom raug.

Kuv vam tias cov ntaub ntawv no qhia meej ntxiv txog lub luag haujlwm thiab qhov tseem ceeb ntawm cov xov kab sib txawv! Xav nug yog tias koj muaj lus nug ntxiv.

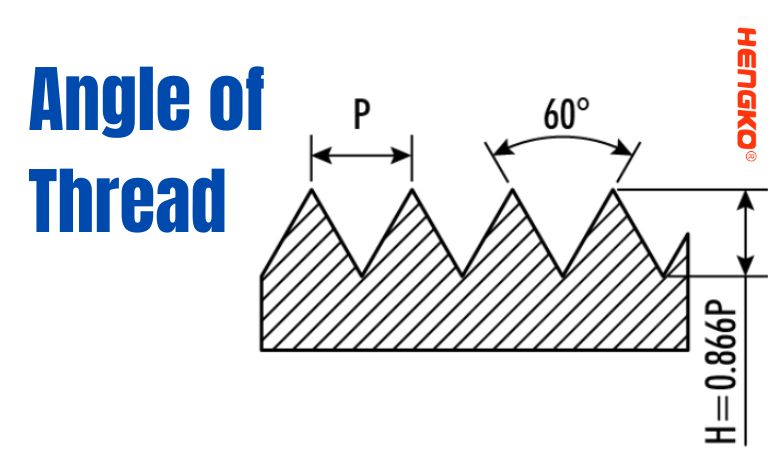

Lub kaum sab xis

* Flank Angle: Lub kaum sab xis ntawm cov xov flank thiab kab perpendicular mus rau axis.

* Taper Lub kaum sab xis: Tshwj xeeb rau tapered threads, nws yog lub kaum sab xis ntawm lub taper thiab qhov nruab nrab axis.

Flank Angle:

* Feem ntau, cov ces kaum flank yog symmetrical (lub ntsiab lus ob flanks muaj tib lub kaum sab xis) thiab tas mus li thoob plaws hauv xov profile.

* Lub kaum sab xis feem ntau yog 60 °, siv rau hauv cov qauv xws li Unified Thread Standard (UTS) thiab Metric ISO threads.

* Lwm cov qauv flank cov ces kaum suav nrog 55 ° (Whitworth threads) thiab 47.5 ° (British Association threads).

* Flank angle cuam tshuam: **1. Lub zog: Lub kaum sab xis loj dua feem ntau muab kev ua haujlwm zoo dua torque tab sis tsis kam ua kom tsis zoo.

2. Kev sib txhuam: cov kaum me me tsim kom muaj kev sib txhuam tsawg dua tab sis tuaj yeem cuam tshuam tus kheej lub peev xwm.

3. Chip tsim: Flank lub kaum sab xis cuam tshuam qhov yooj yim txiav cov cuab yeej tuaj yeem tsim cov xov.

Taper Lub kaum sab xis:

* Lub kaum sab xis no qhia txog tus nqi ntawm txoj kab uas hla hloov raws cov xov tapered.

* Cov kaum sab xis uas muaj xws li 1:16 (National Pipe Thread - NPT) thiab 1:19 (British Standard Pipe Thread - BSPT).

* Taper lub kaum sab xis ua kom muaj kev sib khi nruj, kev sib khi ntawm tus kheej raws li cov xov sib txuas rau ib leeg thaum nruj.

* Nws yog ib qho tseem ceeb rau cov xov tapered kom muaj lub kaum sab xis sib haum rau lub foob foob.

Kev sib raug zoo ntawm Angles:

* Hauv cov xov tsis-tapered, lub kaum sab xis yog tib lub kaum sab xis.

* Rau cov xov tapered, ob qho tib si flank thiab taper ces kaum ua lub luag haujlwm:

1. Lub kaum sab xis txiav txim siab qhov yooj yim xov profile thiab nws cov khoom txuam.

2. Lub kaum sab xis qhia txog tus nqi ntawm txoj kab uas hla hloov thiab cuam tshuam cov yam ntxwv sealing.

Crest thiab Root

* Crest: Sab nraud ntawm xov.

* Hauv paus: qhov innermost, tsim lub hauv paus ntawm xov qhov chaw.

Saum toj no tsuas yog txhais lub crest thiab cag ntawm ib tug xov.

Thaum lawv qhov chaw nyob hauv cov xov zoo li yooj yim, lawv ua lub luag haujlwm tseem ceeb hauv ntau yam ntawm xov muaj nuj nqi thiab tsim.

Nov yog qee cov ntsiab lus ntxiv uas koj tuaj yeem pom nthuav:

Crest:

* Qhov no yog cov ntug sab nraud ntawm cov xov, tsim qhov chaw sib cuag nrog nws cov xov mating.

* Lub zog thiab kev ncaj ncees ntawm lub crest yog qhov tseem ceeb rau kev coj tus kheej load thiab tiv taus hnav.

* Xov puas tsuaj, burrs, lossis imperfections ntawm lub crest tuaj yeem cuam tshuam qhov kev sib txuas lub zog thiab kev ua haujlwm.

Hauv paus:

* Nyob rau hauv qab ntawm cov xov, nws tsim lub hauv paus ntawm qhov chaw nruab nrab ntawm cov xov uas nyob ib sab.

* Qhov tob thiab cov duab ntawm lub hauv paus yog qhov tseem ceeb rau yam xws li:

1. Lub zog: Ib lub hauv paus tob muab cov khoom siv ntxiv rau kev thauj khoom thiab txhim kho lub zog.

2. Kev tshem tawm: Yuav tsum muaj kev tshem tawm cov hauv paus kom txaus kom haum rau cov khib nyiab, roj nplua nyeem, lossis kev tsim khoom sib txawv.

3. Kev sib khi: Hauv qee cov qauv tsim, cov hauv paus profile txhawb kev sib khi.

Kev sib raug zoo ntawm Crest thiab hauv paus:

* Qhov kev ncua deb ntawm lub crest thiab cov hauv paus hniav txhais qhov tob ntawm xov, uas ncaj qha cuam tshuam lub zog thiab lwm yam khoom.

* Cov duab tshwj xeeb thiab qhov ntev ntawm ob qho tib si crest thiab hauv paus yog nyob ntawm tus qauv xov (xws li metric ISO, Unified Coarse) thiab nws daim ntawv thov npaj.

Kev txiav txim siab thiab kev siv:

* Cov txheej txheem xov xov thiab cov lus qhia tshwj xeeb feem ntau txhais cov kev ua siab ntev rau crest thiab hauv paus qhov ntev kom ntseeg tau tias kev ua haujlwm zoo thiab kev sib hloov.

* Hauv cov ntawv thov uas muaj kev thauj khoom siab lossis hnav, xov cov ntaub ntawv nrog cov crests thiab cov hauv paus hniav tuaj yeem raug xaiv rau kev txhim kho durability.

* Cov txheej txheem tsim khoom thiab kev tswj xyuas zoo yog qhov tseem ceeb rau kev ua kom zoo, tsis muaj kev puas tsuaj crests thiab cov hauv paus hniav ntawm fasteners.

Kuv vam tias cov ntaub ntawv ntxiv no ntxiv qhov tob rau koj qhov kev nkag siab ntawm lub luag haujlwm thiab qhov tseem ceeb ntawm crest thiab hauv paus hauv xov. Xav nug yog tias koj muaj lus nug ntxiv lossis cov ncauj lus tshwj xeeb ntsig txog xov tsim uas koj xav tshawb nrhiav!

Dimensions ntawm Xov Hom

Ntawm no yog ib qho kev tawg ntawm qhov ntev ntawm qee cov xov hom uas koj tau hais, nrog rau cov duab kom pom kev zoo dua:

M - ISO Xov (Metric):

* ISO 724 (DIN 13-1) (Cov Lus Nug):

1. Duab:

2. Loj txoj kab uas hla: 3 hli mus rau 300 hli

3. Pitch ntau yam: 0.5mm txog 6mm

4. Xov lub kaum sab xis: 60 °

* ISO 724 (DIN 13-2 txog 11) (Cov xov zoo):

1. Duab:

2. Loj txoj kab uas hla: 1.6 hli mus rau 300 hli

3. Pitch ntau yam: 0.25mm txog 3.5mm

4. Xov lub kaum sab xis: 60 °

NPT - Yeeb Nkab Xov:

* NPT ANSI B1.20.1:

1. Duab:

2. Tapered xov rau cov yeeb nkab txuas

3. Loj txoj kab uas hla: 1/16 nti rau 27 nti

4. Taper lub kaum sab xis: 1:16

NPTF ANSI B1.20.3:

1. Duab:

2. Zoo ib yam li NPT tab sis nrog flattened crests thiab cov hauv paus hniav kom zoo dua sealing

3. Tib qhov ntev li NPT

G/R/RP - Whitworth Xov (BSPP/BSPT):

* G = BSPP ISO 228 (DIN 259):

1. Duab:

2. Parallel yeeb nkab xov

3. Loj txoj kab uas hla: 1/8 nti rau 4 nti

4. Xov lub kaum sab xis: 55 °

* R / Rp / Rc = BSPT ISO 7 (DIN 2999 hloov los ntawm EN10226):

1. Duab:

2. Tapered yeeb nkab xov

3. Loj txoj kab uas hla: 1/8 nti rau 4 nti

4. lub kaum sab xis: 1:19

UNC/UNF - Unified National Xov Xwm:

*Unified National Coarse (UNC):

1. mage:

2. Zoo ib yam li M Coarse Thread tab sis nrog cov ntiv tes raws qhov ntev

3. Loj txoj kab uas hla: 1/4 nti rau 4 nti

4. Xov ib nti (TPI) ntau yam: 20 txog 1

*Unified National Fine (UNF):

1. Duab:

2. Zoo ib yam li M Fine Thread tab sis nrog nti-raws li qhov ntev

3. Loj txoj kab uas hla: 1/4 nti rau 4 nti

4. TPI ntau yam: 24 txog 80

Cov ntaub ntawv saum toj no muab cov ntsiab lus dav dav ntawm qhov ntev rau txhua hom xov. tab sis qhov tshwj xeeb qhov ntev yuav txawv nyob ntawm tus qauv tshwj xeeb thiab daim ntawv thov. Koj tuaj yeem pom cov lus qhia ntxaws thiab qhov ntev hauv cov ntaub ntawv tsim nyog xws li ISO 724, ANSI B1.20.1, thiab lwm yam.

Xav nug yog tias koj muaj lus nug ntxiv lossis xav tau cov ntaub ntawv ntxiv ntawm cov xov xov tshwj xeeb lossis qhov ntev!

SUM

Qhov blog no peb muab cov lus qhia dav dav rauxov tsim, tseem ceeb heev rau kev nkag siab yuav ua li cas cov khoom hauv tshuab thiab engineering tshuab haum ua ke.

Nws npog cov ntsiab lus tseem ceeb ntawm xov poj niam txiv neej, txheeb xyuas txiv neej thiab poj niam xov thiab lawv cov ntawv thov hauv cov lim sintered. peb kuj tseem piav qhia txog xov xov, hais txog qhov tseem ceeb ntawm txoj cai-tes threads hauv feem ntau daim ntawv thov.

Cov ncauj lus kom ntxaws tau muab rau hauv xov tsim, tsom rau cov kab sib txuas thiab cov kab sib txuas, thiab lawv qhov cuam tshuam hauv cov lim sintered.

Yog li phau ntawv qhia no yog qhov tseem ceeb nyeem rau txhua tus neeg tab tom nrhiav kom nkag siab qhov tsis sib xws ntawm cov xov tsim hauv sintered lim. Txawm li cas los xij, Vam tias nws yuav pab tau rau koj

kev paub txog xov thiab xaiv txoj cai xov yav tom ntej, tshwj xeeb rau sintered lim kev lag luam.

Post lub sij hawm: Jan-30-2024