Sintered Hlau yog dab tsi?

Dab tsi yog Sintered Filter Ua Haujlwm Txoj Cai?

Hais luv luv, Vim yog qhov ruaj khov porous ncej,sintered hlau limyog ib qho ntawm cov khoom pom zoo

niaj hnub no. Tsis tas li ntawd, cov ntaub ntawv hlau 'siab kub, siab siab, thiab corrosion kuj tuaj yeem pab koj

yooj yim ua tiav cov haujlwm lim dej hauv ib puag ncig hnyav, Sib cais thiab lim tawm cov impurities ntau dhau

koj tsis xav tau lossis pab koj rho tawm cov roj purity siab dua lossis cov kua dej rau koj qhov project, thiab yog tias koj tseem tab tom nrhiav

qee lub Hoobkas tiag tiag rau OEM sintered hlau lim rau koj qhov system pom, thov mus saib ntawm no kom pom

tusSab saum toj Industrial Lim Manufacturers.

Tej zaum koj yuav tsum tsis txhob hnov lo lus no ntau hauv koj lub neej txhua hnub.

Tab sis tam sim no, sintered hlau siv ntau thiab ntau nyob rau hauv ntau yam lag luam, sintered hlau tau pib los ua.

tustechnology tseem ceeb hauv qee qhov kev tsim khoom.

CesDab tsi tiag yog Sintered Hlau?

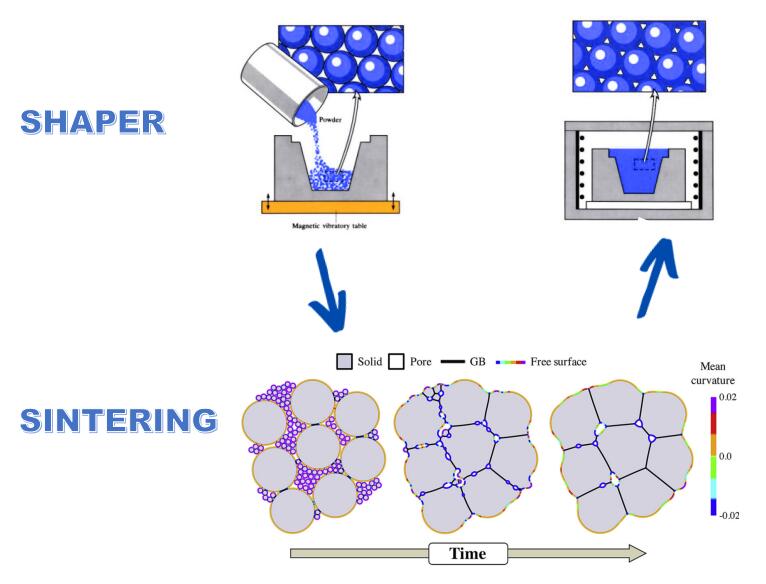

Qhov tseeb, nws yog ib ceg ntawm cov hmoov metallurgy kev lag luam, luv luv, yog 316L stainless hlauhmoov los ntawm pwm

shaping, kub sintering rau hauv cov duab thiab kev ua haujlwm ntawm cov txheej txheem uas peb xav tau.

Tom qab ntawd, Ua ntej, sintered.Dab tsi yog sintered?

Sintering yog txheej txheem ntawm compactingthiab tsim ib qho khoom loj ntawmkhoom

los ntawm tshav kub los yog siab tsis melting nws mus rau qhov chaw ntawm liquefaction. Sintering yog ib feem ntawmkev tsim khoom siv

nrog hlau, ceramics,yas, thiab lwm yam ntaub ntawv.Wikipedia

Raws li Wikipedia piav qhia, ntau yam khoom siv tau tuaj yeem sintered, thiab cov khoom sib txawv sintered khoom muaj

txawvdaim ntawv thov. Tom qab ntawd peb nyiamlos tham cov ntsiab lus ntxiv txog sintered hlau.

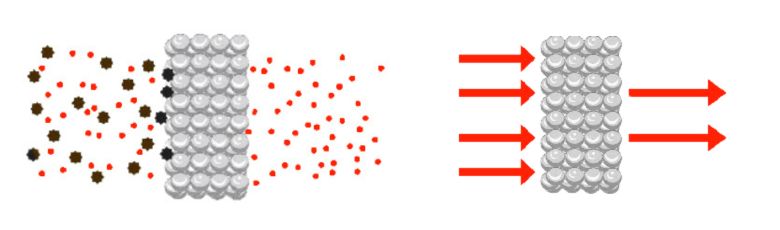

1. Kev lim dej thiab kev sib cais 2. Kev txwv cov dej

3. Txo suab nrov 4. ruaj khov ntws

Keeb kwmntawm Sintering Hlau

Leej twg Inventions lub sintering thiab pib siv cov khoom sintered?

Raws li cov ntaub ntawv keeb kwm, cov txheej txheem sintering tshwm sim thaum lub sij hawm thib ob kev lag luam kiv puag ncig 18th caug xyoo.

hauv Sweden thiab Denmark. Sintered hlau tau pom thaum lub sij hawm smelting txheej txheem nyob rau hauv thee mines. Tab sis txog xyoo 1980, tib neeg

pib siv cov hlau sintered rau cov roj lim. Thiab rau xyoo 1985, thawj zaug siv HyPulse® filtration technology rau

nruam slurry roj pom.

Yog li ua tau, koj tuaj yeem tshawb xyuas raws li hauv qab no, muaj lub sijhawm tseem ceeb 3-tsim.

Yog li ua tau, koj tuaj yeem tshawb xyuas raws li hauv qab no, muaj lub sijhawm tseem ceeb 3-tsim.

1.Ancient keeb kwm

* Hnub nyoog Bronze:

Cov pov thawj ntxov tshaj plaws ntawm cov txheej txheem sintering zoo li hnub rov qab mus rau Bronze Age, qhov twg cov khoom hlau yog

yuav tsim los ntawm cua sov thiab compressing hlau hmoov.

* Hnub nyoog hlau:

Ironworking cov txheej txheem, nrog rau kev siv cov rhuab thiab compressed hlau ore, tej zaum yuav muaj incorporated

cov ntsiab lus ntawm sintering.

2.Industrial Revolution thiab Kev Txhim Kho Thaum Ntxov

* XIX caug xyoo:

Lub Industrial Revolution pom muaj kev txaus siab rau kev ua haujlwm hlau. Hmoov metallurgy,

ib tug precursor rau sintering, pib tshwm sim raws li ib tug txheej txheem rau tsim cov khoom hlau los ntawm cov ntaub ntawv hmoov.

* Thaum Ntxov 20th Century:

Kev nce qib hauv metallurgy thiab cov ntaub ntawv tshawb fawb tau ua rau muaj kev txhim kho ntxiv hauv cov txheej txheem sintering.

Kev tsim cov hlau ntxeem tau thiab cov kabmob siv cov txheej txheem sintering tau dhau los ua ntau dua.

3.Ntawm Era thiab Kev Txhim Kho Kev Siv Tshuab

* Mid-20th caug xyoo:

Sintering thev naus laus zis tau ntsib kev loj hlob tseem ceeb thaum nruab nrab xyoo pua 20th, uas tau tsav los ntawm kev nce qib

nyob rau hauv hmoov metallurgy thiab cov ntaub ntawv science. Txoj kev loj hlob ntawm high-kev ua tau zoo sintered cov ntaub ntawv rau

aerospace, automotive, thiab kev lag luam kev siv tau los ua qhov tseem ceeb.

*Late 20th thiab Early 21st Centuries:

Lub lig 20th thiab ntxov 21st centuries tau pom txuas ntxiv innovation nyob rau hauv sintering technology. Txoj kev loj hlob

ntawm cov txheej txheem sintering siab heev, xws li xaiv laser sintering (SLS) thiab binder jetting, nthuav dav ntau yam

ntawm cov ntaub ntawv thiab cov duab complex uas yuav ua tau.

Kev siv niaj hnub

* Automotive:

Cov ntaub ntawv sintered tau siv dav hauv cov khoom siv tsheb, suav nrog cov iav, bearings, thiab lim.

Lawv cov khoom, xws li lub zog, durability, thiab porosity, ua rau lawv zoo tagnrho rau kev thov.

* Aerospace:

Sintered cov ntaub ntawv yog siv nyob rau hauv aerospace Cheebtsam vim lawv lub teeb yuag, high-lub zog zog.

Lawv muaj nyob rau hauv qhov chaw xws li turbine hniav, roj nozzles, thiab tshav kub exchangers.

* Cov khoom siv kho mob:

Cov ntaub ntawv sintered yog siv rau hauv ntau yam khoom siv kho mob, suav nrog cov khoom cog, cov khoom siv, thiab cov khoom siv kho hniav.

Lawv biocompatibility thiab customizable zog ua rau lawv haum rau cov ntawv thov.

* Cov ntawv thov kev lag luam:

Cov ntaub ntawv sintered muaj ntau daim ntawv thov kev lag luam, suav nrog hauv kev pom, hluav taws xob, thiab lub zog cia.

Lawv versatility thiab kev ua tau zoo yam ntxwv ua rau lawv muaj nuj nqis nyob rau hauv ntau yam kev lag luam.

Xaus

Txawm li cas los xij, Sintering thev naus laus zis tau hloov pauv ntau ntau xyoo dhau los, los ntawm nws cov keeb kwm yav dhau los mus rau nws cov kev siv niaj hnub no.

Los ntawm kev nce qib txuas ntxiv hauv cov ntaub ntawv tshawb fawb thiab kev tsim khoom, cov ntaub ntawv sintered tau dhau los

cov khoom tseem ceeb nyob rau hauv ntau yam kev lag luam, pab txhawb kev lag luam thiab kev tsim kho tshiab.

Yog li Dab tsi yog Sintered Hlau Lim?

Ib qho yooj yim txhais ntawm sintered hlau lim:

Nws yog cov hlau lim uas siv cov hmoov hlau hmoov ntawm tib yamparticle lojua kom zoo li tus stamping,

high-temperature sintering txheej txheem. Sintering yog txheej txheem ntawmmetallurgy siv hmoov-lojlub cev ntawm

sib txawv hlau thiab alloys tom qab stamping.

Metallurgy tshwm sim los ntawm qhov sib txawv ntawm qhov kub thiab txias hauv qab lub melting point ntawm high-temperature furnaces.

Cov hlau thiab alloysfeem ntau siv niaj hnub nomuaj xws li txhuas, tooj liab, npib tsib xee, bronze, stainless hlau,

thiab titanium.

Muaj cov txheej txheem sib txawv uas koj tuaj yeem siv los tsim cov hmoov. Lawv suav nrog kev sib tsoo, atomization,

thiab tshuaj decomposition.

Dab tsi yog Sintering Hlau Lim Manufacturing txheej txheem

Tom qab ntawd, yog li ntawm no, peb nyiam xyuas cov txheej txheem nthuav dav ntawm Hlau lim manufacturing. Yog xav paub ntxiv, thov mus saib hauv qab no:

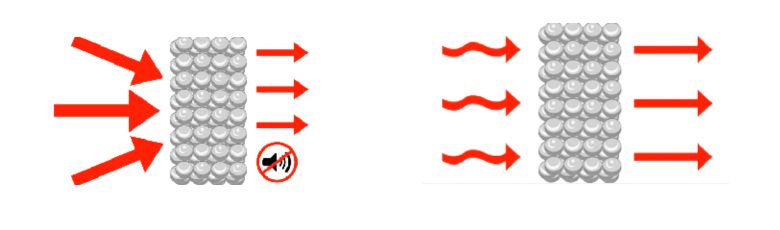

1.) Sintering yog dab tsi, Vim li cas siv Sintering?

Yooj yim txhais sintering yog hlau hmoov yog sib koom ua ke los ntawm kev kub siab thiab lwm txoj hauv kev rau hauv

qhov xav tau module.Hauv micron ntau, tsis muaj kev txwv lub cev ntawm cov hmoov hlau hmoov,

uas yog vim li cas peb thiaj tswj tau qhov pore nrug

los ntawm cov txheej txheem ntau lawm.

Cov ntxeem tau ntawm cov txheej txheem sintering muab cov duab ruaj khov ntawm cov hlau thiab muab

cov khoom nrog lubkev ua tau zoo ntawm kev pom zoo.

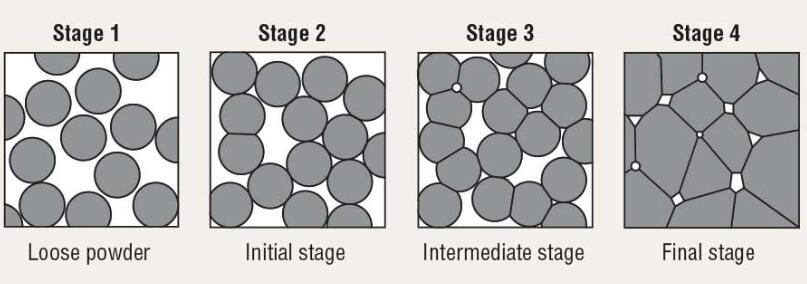

2.)3-Lub ntsiabCov kauj ruam ntawm Sintered Hlau Lim Manufacturing

A: Thawj kauj ruam yog kom tau txais lub zog hlau.

Cov hmoov hlau, Koj tuaj yeem tau txais cov hmoov hlau los ntawm kev sib tsoo, atomization, lossis tshuaj decomposition.

Koj tuaj yeem ua ke ib qho hlauhmoov nrog lwm cov hlau los ua ib qho alloy thaum lub sij hawm fabrication,

los yog koj siv tau ib qho hmoov xwb. Qhov zoo ntawm sintering yog qhov ntawdnws tsis hloov lub cev

cov khoom ntawm cov khoom siv hlau. Cov txheej txheem yog yooj yim heev uas cov ntsiab lus hlau tsis hloov.

B: Stamping

Cov kauj ruam thib ob yog nchuav cov hmoov hlau rau hauv cov pwm npaj ua ntej uas koj tuaj yeem tsim cov lim.

Lub lim los ua ke yog tsim nyob rau hauv chav tsevkub thiab nyob rau hauv stamping. Tus nqi ntawm lub siab siv

nyob ntawm cov hlau koj siv, raws li cov hlau sib txawv muaj qhov sib txawv elasticity.

Tom qab muaj kev cuam tshuam los ntawm kev kub siab, cov hmoov hlau yog compacted nyob rau hauv pwm los ua ib qho khoom lim.Tom qab lub

high-pressure cuam tshuam txheej txheem, koj tuaj yeemtso cov hlau lim npaj rau hauv qhov cub kub kub.

C: High-temperature Sintering

Nyob rau hauv cov txheej txheem sintering, cov hlau hais yog fused los tsim ib chav tsev yam tsis tau mus txog lub melting point.

Lub monolith no muaj zog,nruj, thiab ntxeem tau lub lim raws li cov hlau.

Koj tuaj yeem tswj cov porosity ntawm cov lim dej los ntawm cov txheej txheem raws li qhov ntws ntawm cov huab cua los yog kua yuav tsum tau lim.

Lub sintered media grade designation yog sib npaug rau qhov nruab nrab ntws pore, los yog qhov nruab nrab pore loj ntawm lub lim.

Sintered hlau xov xwm yogmuaj nyob rau qib 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 thiab 100. Qhov ntsuas pom hauv

kua rau cov xov xwm qib 0.2 txog 20 yog nyob nruab nrab ntawm 1.4 thiab 35 µmkiag li. Qhov ntsuas ntsuas hauv cov pa roj

los ntawm 0.1 mus rau 100 µm absolute.

Vim li cas thiaj siv hlau sintering los ua lim?

Qhov no yog ib lo lus nug zoo, yog vim li cas siv hlau los ua lim?

Cov lus teb yog qhov yooj yim, thiab txawm tias muaj ntau yam laj thawj, tus nqi yog qhov tseem ceeb tshaj plaws.

Vim li cas Tus Nqi?

Yog lawm, cov hlau sintered muaj cov qauv ruaj khov thiab tuaj yeem rov qab siv dua, huv si, thiab siv ntau zaus.

Thiab tseem, cov hlau sib txawv muaj lub cev thiab tshuaj lom neeg ruaj khov thiab tsis yooj yim puas.

Nws yog vim li cas ntau thiab ntau Sintered Lim tau siv nyob rau hauv kev lag luam sib txawv.

Dab tsi yog Cov Khoom Xaiv rauSintered lim?

Nrog rau kev nce qib ntawm cov hmoov metallurgy technology, muaj ntau txoj kev xaiv

cov ntaub ntawv rau sintered hlau lim,

Koj tuaj yeem xaiv los ntawm ntau lwm cov hlau thiab alloys kom tau raws li cov kev xav tau tshwj xeeb ntawm siab dua

kub thiab siab, corrosionkuj thiab lwm yam, Cov khoom siv hlau tseem ceeb xws li:

-

Stainless hlau lim; 316L, 304L, 310, 347 thiab 430

-

Bronze

-

Inconel® 600, 625 thiab 690

-

Nickel 200 thiab Monel® 400 (70 Ni-30 Cu)

-

Titanium

-

Cov hlau nplaum

Sinteredstainless hlau lim, suav nrog lim cartridges, daim hlau, thiab cov raj ua los ntawm stainless hlau

304 thiab 316, muaj kev lim dej siab, kev ua haujlwm ntev, thiab kev siv ntau yam hauv cov ntawv thov rau ob qho tib si kua

thiab gas filtration. Lawv ua tau zoo nyob rau hauv high-temperature thiab corrosive ib puag ncig.

Ntau thiab ntau dua hlau yuav siv rau yav tom ntej.

8-Qhov zoo ntawm Sintered Hlau Lim

1.) Corrosion kuj

Feem ntau cov hlau yog inherently resistant rau corrosion, xws li sulfides, hydrides, oxidation, thiab lwm yam.

2.) Kev tshem tawm cov kab mob zoo dua

Kho qhov porosity ntawm daim cartridge rau cov kua dej txhais tau tias koj tuaj yeem ua tiav qhov zoo meej

lim koj xav tau thiab tau ibkua dej tsis huv. Tsis tas li ntawd, txij li lub lim tsis corrode,

cov lim cov tshuaj tiv thaiv tsis ua rau muaj qhov tshwm simntawm cov kab mob hauv cov kua dej.

3.) Siab Thermal Shock

Thaum lub sij hawm tsim cov txheej txheem, siab kub yog generated, thiab lub cev muaj zog ntawm

cov hlau no pab nquslub lim zoo thermal shock. Yog li ntawd, koj tuaj yeem siv cov no

filters nyob rau hauv ib tug ntau yam ntawm daim ntaub ntawv nyob ntawm sebthermal ntau ntawm daim ntawv thov.

Zoo thermal shock kuj ua kom cov dej pom zoo yam tsis tas yuav txhawj txog

cua sov ntawm daim ntawv thov.

4 、) Tsim nyog siab poob

Asintered hlau limtuaj yeem tswj cov kua dej hauv koj daim ntawv thov, yog li ua kom ntseeg tau

kev ua haujlwm siab tshaj plaws.

Kev poob qis me ntsis tuaj yeem ua mob rau koj daim ntawv thov.

5.) Kub thiab siab tiv taus

Koj tuaj yeem siv cov lim dej no hauv cov ntawv thov nrog qhov kub thiab txias yam tsis muaj

txhawj xeeb txog koj lub lim dej.

Siv cov sintered hlau lim hauv cov txheej txheem ntawm cov tshuaj tiv thaiv thiab roj

cov nroj tsuag kho kom ntseeg tau kojtau cov txiaj ntsig zoo tshaj plaws.

6.) tawv thiab tiv taus tawg

Lwm qhov txiaj ntsig ntawm kev siv lub sintered hlau lim yog tias nws muaj zog thiab tiv taus

tawg.

Thaum lub sijhawm tsim khoom, kev sib txuas ntawm cov hlau tshwm sim ntawm qhov kub thiab txias

hauv qab lub melting point.

Cov khoom uas tshwm sim yog ib qho tawv sintered hlau lim uas tuaj yeem tiv taus ntau yam

hnyav ib puag ncig.

Piv txwv li, koj tuaj yeem siv nws hauv cov ntawv thov uas xav tau kev sib txhuam yam tsis muaj kev ntshai ntawm kev tawg.

7.) Zoo Siab Tolerance

Kev zam zoo txhais tau hais tias koj lub lim dej sintered tuaj yeem lim koj cov kua dej yam tsis muaj kev cuam tshuam.

Thaum koj pom tiav lawm, cov sintered hlau lim yuav khaws nws lub cev.

Txawm li cas los xij, nws yuav pab tau yog tias koj paub tseeb tias cov hlau koj xaiv rau koj lub lim yuav tsis

hnov mob nrog cov kua uas koj tau lim

8.) Ntau yam ntawm Geometric Muaj peev xwm

Sintered cartridges tso cai rau koj txaus siab rau ntau yam kev xaiv geometric. Koj tuaj yeem ua tiav

qhov no thaum ntxig cov hmoovnyob rau hauv cov xim thaum tsim khoom.

Cov pwm yog ib qho uas yuav tsum tsim koj lub lim.

Yog li ntawd, koj muaj kev ywj pheej los ua tus tsim raws li koj cov specifications.

Piv txwv li, yog tias koj daim ntawv thov xav tau lub lim me me, koj tuaj yeem yooj yim tswj tus qauv

kom tau ib qho me me

sintered hlau lim.Ib yam li ntawd, yog tias koj daim ntawv thov muaj tus qauv tsim, koj tuaj yeem yooj yim

manipulate tus tsim nyob rau hauv lubpwm thaum tsim khoom.

Sintered hlau lim ua haujlwm li cas?

Qhov teeb meem no kuj tuaj yeem hais tau tias yog txoj hauv kev ua haujlwm ntawm sintered hlau lim. Coob leej xav tias

tias lo lus nug no yognyuaj heev los teb, thiab nws tsis yog.Tej zaum koj yuav xav tsis thoob los ntawm qhov no, tab sis tej zaum koj

yuav tsis yog tom qab nyeem kuv cov lus piav qhia.

Sintered hlau lim yog cov lim dej zoo heev. Kev sau cov kab mob tshwm sim ntawm qhov chaw

cov kua dej; thaum lubCov kua dej dhau los ntawm cov hlau lim, lubloj hais thiab kab mob yuav

sab laug ntawm ib sab ntawm daim cartridge, tab sis thaum twgxaiv qhov pom zoo rau koj cov kua, koj

yuav tsum paub tseeb tiasnws tuaj yeem lim cov kev xav tau.

* Cov kev xav tau no suav nrog

1. Muaj peev xwm Retention Backwash

2. Siab poob

Rau kev poob siab, koj yuav tsum xav txog ntau yam.

Cov xwm txheej no suav nrog

ACov kua dej viscosity, dej tshaj tawm raws li nws ntws los ntawm cov khoom lim dej, thiab cov yam ntxwv tsis huv.

BCov yam ntxwv ntawm cov kab mob muaj xws li particle shape, ntom, thiab loj.

Yog tias cov kab mob sib kis nyuaj thiab tsis tu ncua, tsim lub ncuav mog qab zib tuab, ces qhov pom ntawm qhov chaw yog qhov tsim nyog.

* Cov txiaj ntsig ntawm sintered hlau pom nyob ntawm

1.qhov nce siab poob mus rau qhov chaw uas qhov siab kawg mus txog.

2. cov dej tsis tu ncua.

Koj tuaj yeem ua tiav cov xwm txheej kawg los ntawm kev ua kom cov kab mob sib kis uas nce mus rau qhov chaw uas cov kua dej poob.

Lub siab no poob mus tas li kom txog thaum qhov siab tshaj plaws poob rau qhov muab viscosity thiab txaus tus nqi ntws mus txog.

Lwm qhov teeb meem tseem ceeb yog kev ntxuav rov qab ntawm cov lim dej, uas yog ua los ntawm kev nias lub roj rau ntawm qhov screen thiab sai.

qhib lub backwash tawm valveraws li lub backwash tshwm sim.

Lub siab rov qab instantaneous siab sib txawv yogtsim tawm. Nws zoo tshem cov kab mob ntawm lub lim

yam nto. Rov qabntws ntawm cov kua huv huv los ntawm cov khoom lim tshem tawm cov kab mob thiab coj lawv

tawm ntawm lub lim.

Qhov nce tsis tu ncua ntawm kev poob siab qhia tau hais tias muaj kev sib npaug thiab sib npaug ntawm cov kab mob loj.To

ua tau zoo ib yamkev ua tau zoo, koj yuav tsum xyuas kom meej tias cov khoom lim lub siab poob siab ruaj khov.Yog kub

ntawm cov kua hloov, nws cuam tshuamviscosity ntawm cov kua. Nyob rau hauv cov ntaub ntawv no, lub siab poob hla lub limelement yuav

nce thiab tsis ua tiav cov nyhuv pom.

Yog li ntawd, koj yuav tsum tswj xyuas qhov kub thiab txias ua haujlwm ntawm lub lim thaum lub sij hawm pom thiab

xyuas covqhov kub ntawm cov kua thiab lub siab.Thaum ntxuav lub lim, koj yuav tsum ua raws li cov

txheej txheem ntxuav rov qab.

Sintered Hlau Lim ua haujlwm li cas?

Koj tuaj yeem nkag siab yooj yim thaum koj tshawb xyuas cov hauv qab noDaim duab qhia kev ua haujlwm

Raws li nram no yog lub ntsiab8- Homntawm Covua hauj lwm hauv paus ntsiab lus ntawm hlau filtration, vam tias nws yuav pab tau rau koj

nkag siab ntau ntxivrau li cassintered hlau lim yuav pab taurau filtration kua, roj thiab lub suab.

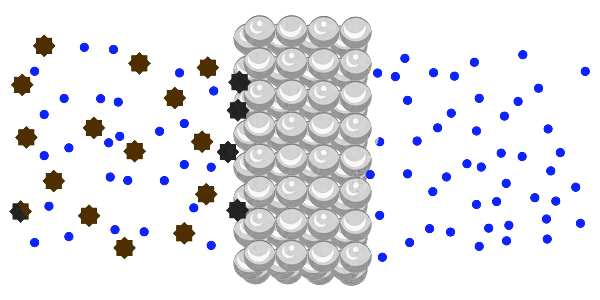

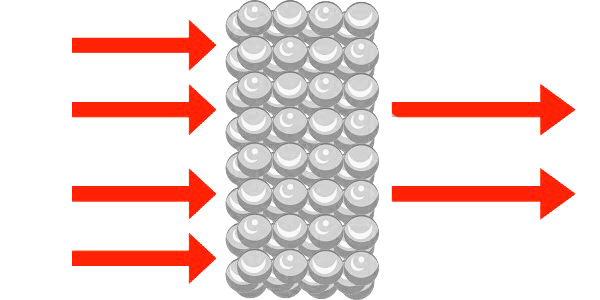

1.) Liquid & Gas Lim / Sib cais

Sintered Hlau lim tuaj yeem txo lossis tshem tawm tag nrho cov teeb meem ntawm cov pa roj lossis kua nruab nrab.

Particulate teeb meem tuaj yeemsuav nrog tab sis tsis txwv rau cov khoom raug tshem tawm (sediment, hlau chips, ntsev, thiab lwm yam),

algae, kab mob, fungi spores, thiab tsis xav tauchemical/biological contaminants. Hlau lim pore qhov ntau thiab tsawg

tuaj yeem ua tau los ntawm 0.2 µm - 250 µm.

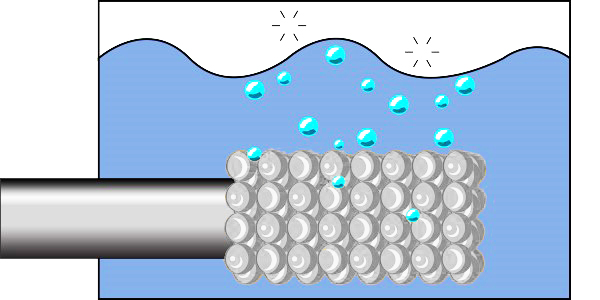

2.)Sparger

Qee qhov kev siv Sparging:

Soda Carbonization

Npias Carbonization

OxygenStripping of Edible Oils

Sparging yog qhov kev taw qhia ntawm cov roj rau hauv cov kua. Nws yog siv los tshem tawm cov pa tsis xav tau yaj

(oxygen stripping) los yogib tug yaj volatile kua. Nws kuj tseem siv tau los qhia cov roj rau hauv cov kua (carbonization).

Cov tsoos sparging tsim npuasnrog ib txoj kab uas hla ntawm 6 mm. PM lim sparging tso cai rau ib qho me me

npuas txoj kab uas hla, yog li nce qhov chaw saum npoo ntawmcov npuas tsim kom muaj txiaj ntsig zoo dua

daim ntawv thov los ntawm kev txo cov sijhawm ua haujlwm.

3.) Lub tshuab ua pa

Sintered hlau lim kuj siv los uacov pa ua panyob rau hauv lub tog raj kheej, gearboxes, manifolds, hydraulic systems,

reservoirs, thiab lwm yam systems. Breather vents cia siab sib npaug thiab cua / roj hauv thiab tawm ntawm lub cev

thaum thaiv cov khoom me me los ntawm kev nkag mus rau qhov system. Sintered bronze lim discs muaj txiaj ntsig tshwj xeeb

nyob rau hauv hluav taws xob motors, tiv thaiv kev nkag ntawm cov plua plav, ya raws, thiab lwm yam kab mob thaum tseem tso cai rau huab cua

kev sib pauv, uas yog qhov tseem ceeb rau kev tswj hwm qhov chaw sab hauv ntawm lub cev muaj zog thiab ua kom nws zoo

ua haujlwm thiab ua haujlwm ntev. Cov ntxaij lim dej hlau tuaj yeem rov qab ntxuav kom tshem tawm cov teeb meem, muab lawv ntev dua

lifespan raws li ib tug breather vent dua lwm yam lim xov xwm.

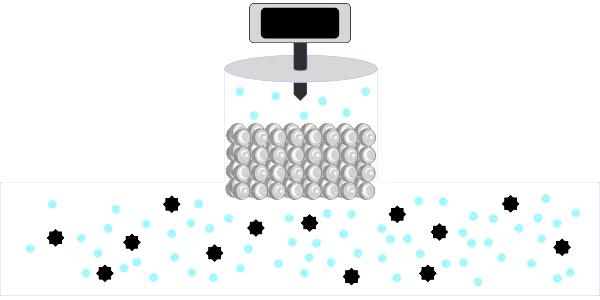

4.) Kev tiv thaiv Sensor

Sintered Hlau Lim kuj tseem tuaj yeem tiv thaiv cov khoom siv hluav taws xob ua lub hau npog, xws li cov ntsuas kub,

ntau yam sensors,tus yuam sijcov khoom siv kho mob, thiab lwm yam khoom rhiab los ntawm dej,

kua, sediment, plua plav, thiabkev hloov pauv siab.

5.) Flow Control (Throttling / Dampening)

Ib qho tshwj xeebsintered limtuaj yeem tswj cov dej ntws hauv huab cua, roj, lub tshuab nqus tsev, thiab cov kua dej ntws. Cov

lim lub cevpore qhov ntau thiab tsawgtso cai rau ua kom zoo ib yam, rov ua dua kev tswj hwm thiab tiv thaiv li qub, sensors,

thiab lwm yam hauv qab dejhauv qhov system los ntawmcov kab mob. Flow tswj yog siv nyob rau hauv xws li

daim ntawv thov raws li pneumatic timers, gas mov tswjcov ntsiab lus, thiab ncua sij hawmcov ntsiab lus hauv

automotive applications.

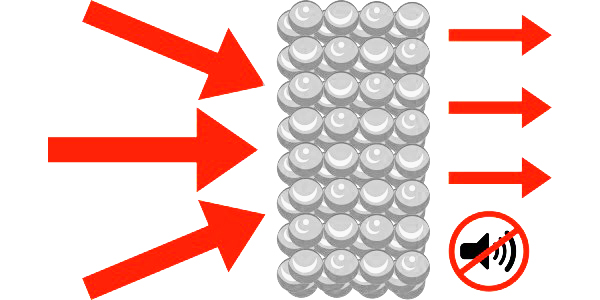

6.) Cua Txias Silencers

sintered lim kuj tuaj yeem welded los yog sinter-bonded rau txhua qhov yuav tsum tau haum, tso cai rau lawv ua hauj lwm raws li ib tug

tso pa tawm Silencer.Lub lim tsis tuaj yeem tsuas yog tiv thaiv solenoids thiab manifolds los ntawm cov kab mob hauv lub cev

system tab sis kuj txo cov suab nrovtheem ntawm cov pa tawm ntawm qhov system. Covcua tso pa tawm Silencerlim

kujtxo cov cua tshuab tawm ntawm qhov system, uasminimizes contaminants wafting, Tiv thaiv

ib puag ncig.

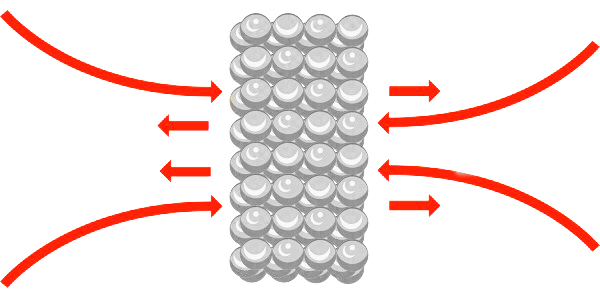

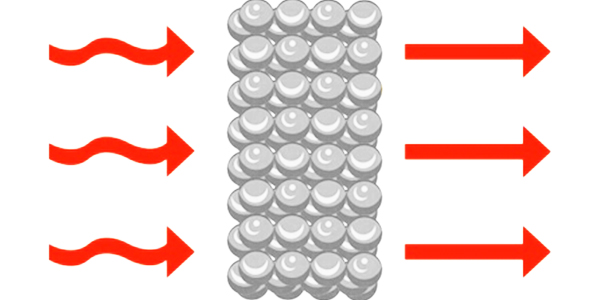

7.) Flow / Siab sib npaug

Sintered lim tuaj yeem sib npaug thiab tswj tau lub cev ntws thiab siab. Kev sib npaug tiv thaiv

systems tiv thaiv surgentawm cov kua thiab tsim kom muaj kev sib xws thaum cov pa roj los yog kua txav mus

lub cev pores.

Dab tsi yog sintered lim siv rau?

Rau lo lus nug no, Ua tau ntau tus neeg yuav nug Dab tsi yog daim ntawv thov ntawm sintered hlau lim?

Tom qab xws li cov txheej txheem nyuaj, qhov twg yuav sinteredhlau lim cartridgessiv?

Qhov tseeb yog tias koj tuaj yeem pom cov lim dej no hauv ntau qhov kev lag luam.

Cov ntawv thov uas muaj xws li hauv qab no.

1) Kev ua tshuaj lom neeg

Koj tuaj yeem nrhiav sintered hlau lim hauv cov tshuaj hnyav thiab roj ua lag luam, suav nrog

kev lag luam nuclear.Qhov corrosion, kub siab, thiab tsis muaj tshuaj lom neeg ua rau sintered hlau

lim ib qhov zoo dua hauv

kev lag luam chemical processing.

2) Petroleum refining

Rau roj refining, kom zoo lim cov roj sib txawv

Peb yuav tsum siv cov ntxaij lim dej sib txawv raws li qib qib kom ua tiav qhov pom ntawm cov

tshwj xeeb roj los ntawmcov khoom noj khoom haus.Yog lawm, sintered hlau lim tuaj yeem pab koj ua tiav lub hom phiaj no.

Vim tias cov ntxaij lim dej hlau tsis muaj tshuaj lom nrog cov roj.

Yog li ntawd, cov roj tshwj xeeb yuav tsis muaj kab mob tom qab lim.

Tsis tas li ntawd, koj tuaj yeem siv nws ntawm qhov kub txog li 700 °, uas yog ib qho ntawm cov roj refining.

3.) Kev tsim hluav taws xob

Lub tshuab hluav taws xob tsim hluav taws xob xav tau kev ua haujlwm tas li ntawm lub turbine. Tseem, cov

ib puag ncig hauvkoj turbineua haujlwm feem ntau yuav tsum tau pom kom ua tiav lub cev ntawm cov dej hauv

uas lub turbine tsis muaj impurities.

Yog hais tias lub turbine yog overloaded nrog impurities, nws yuav cua thiab tiv thaiv lub turbine los ntawm rotating,

thiab ces lub turbine yuavtsis tsim hluav taws xob. Koj tuaj yeem siv sintered hlau lim los xyuas kom meej

kev tsim hluav taws xob zoo thiab muaj txiaj ntsig zoo.

Cov lim dej no yog siv los tsim hluav taws xob los ntawm kev lim dej los ntawm lub turbine.

Vim lawv tsis eroded los ntawm dej, lub turbine yuav ua hauj lwm ntev.

4.) Natural gas ntau lawm

Lwm qhov tseem ceeb ntawm daim ntawv thov rau sintered hlau lim yog cov roj ntau lawm.

Sintered hlau lim yog qhov tseem ceeb heev hauv kev tsim cov roj vim tias lawv tsis hnov mob nrog cov roj,

thiab koj tuaj yeem siv lawvnyob rau hauv ib puag ncig sib txawv.

5.) Khoom noj khoom haus thiab dej haus

Hlau lim extract cov as-ham tseem ceeb thiab kua txiv hmab txiv ntoo hauv kev lag luam ua zaub mov thiab dej haus.

Hlau lim zoo lim thiab tiv thaiv cov as-ham los ntawm kev ntxuav tawm thaum ua haujlwm.

Qhov zoo ntawm tib lub tshuab lim hlau yog tias lawv tsis hnov mob nrog cov khoom noj tshwj xeeb lossis dej haus.

Thaum siv cov ntxaij lim dej no lav qhov zoo ntawm koj cov txheej txheem ntau lawm.

9. Ua li casSintered Hlau LimHENGKO tuaj yeem muab tau?

HENGKO cov khoom tseem ceeb 316L, 316 thiab bronze sintered hlau filers. lub ntsiab zoo xws li cov npe hauv qab no:

1.Stainless hlau limDisc,

2.StainlessHlau LimTube,

3.Stainless Hlau LimPhaj,

4.Stainless hlau limkhob,

thiab lwm yam, txhua yam uas koj qhov project xav tau.

Tseeb, peb muabKev Pabcuam OEM

1.OEMCov duab:Disc, khob,Tube, Phaj ect

2.CustomizeLoj, Qhov siab, dav, OD, ID

3.Customized Pore Loj /Apertureslos ntawm 0.1μm - 120μm

4.Customize txawv Thickness

5. Mono-txheej, Multi-layer, Mixed Materials

6.Integrated tsim nrog 304 stainless hlau vaj tse

Rau koj cov ntsiab lus OEM ntxiv, thov hu rau HENGKO Hnub no !

Tseem Muaj Cov Lus Nug Zoo Li Xav Paub Txog Cov Lus Qhia Ntxiv Rau Cov Humidity Monitoring Sensor,

Thov koj xav tiv tauj peb tam sim no.

Kuj Koj Ua TauXa email rau pebDirectly Raws li:ka@hengko.com

Peb yuav xa rov qab nrog 24-teev, Ua tsaug rau koj tus neeg mob!

Xa koj cov lus rau peb:

Post lub sij hawm: Aug-20-2022