-

10Pcs / Lot HD Flat slotted thiab sintered ntxeem tau hlau bronze muffler silencer M5 1/8 "...

HD Exhaust Muffler Bronze Model G 1/8 '' 1/4 '' 3/8 '' 1/2 '' 3/4 '' 1'' * Cov ntaub ntawv hauv daim ntawv no yog rau siv xwb Pneumatic Sintered Muff ...

Saib nthuav dav -

Sintered Bronze Muffler 40 Micron Siab nyem Valve Waterproof Breather Vent Fitting

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

Pneumatic tso pa muffler silencer cua ntws tswj truncated cone nrog qhov txiav 1/8 ...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

HBSL-SEB Sintered Bronze Brass Exhaust Lim Silencer 1/2 Txiv neej NPT Xov Pneumatic Mu...

HBSL-SEB Muffler Silencer Model M5 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' 1 1/4'' 1 1/2'' 2'' Pneumatic Sintered Mufflers Lim siv ...

Saib nthuav dav -

HENGKO Nqis ntxeem tau hmoov hlau sintered ax100 cua pneumatic muffler

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

HB Micron Stainless hlau Bronze Sintered Lim Element 1/4 "Air Pneumatic Flow S ...

HD Exhaust Muffler Bronze Model 1/8 '' 1/4 '' 3/8 '' 1/2 '' 3/4 '' 1'' Pneumatic Sintered Mufflers Lim siv ntxeem tau sintered bronze lim ...

Saib nthuav dav -

Ua pa vents nrog txiv neej xov, tooj dag tooj dag stainless hlau SS 316 ASP-1/2/3/4/6/8 BV

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim caij ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

HBSL-MA V sintered tooj dag pneumatic ca silencer muffler cua tso suab nrov txo thiab ...

Muffler Silencer Model G M5 1/8 '' 1/4 '' 3/8 '' 1 ...

Saib nthuav dav -

Brass cua tshem tawm pneumatic muffler qhov cua nrog 1/8 "1/4" 3/8R ...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

HENGKO Sintered Porous Hlau Pneumatic Cheebtsam / muffler rov valve roj lim uas ...

Roj Valve Lim Bronze Model M5 M5 M5 1/8 '' 1/4 '' Pneumatic Sintered Mufflers Lim siv ntxeem tau sintered bronze lim ele ...

Saib nthuav dav -

ECMO System Ua tsis taus pa accessories rau ECMO "lub ntsws dag" khoom

ECMO, lossis extracorporeal membrane pulmonary oxygenation, yog txheej txheem kev txhawb nqa lub neej uas siv cov cuab yeej tshwj xeeb los kos cov ntshav tawm ntawm lub plawv, exc ...

Saib nthuav dav -

HSC Pneumatic Sintered Stainless Hlau Brass Exhaust Muffler Silencer Fitting Suab nrov Fil ...

HD Exhaust Muffler Bronze Model 1/8 '' 1/4 '' 3/8 '' 1/2 '' 3/4 '' 1 '' 1-1 / 4 '' Pneumatic Sintered Mufflers Lim siv ntxeem tau ...

Saib nthuav dav -

3 70 micron sintered micropore ntxeem tau hlau bronze tooj liab tso muffler lim qhov chaw

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

Flow control exhaust muffler silencers ntxeem tau hlau sintered stainless hlau cua ua pa ...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

Microns Pneumatic Plus Sintered Hlau Bronze Breather Vent - tooj dag lub cev 1/4 "...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

HBSL-SSDM Txiv neej Breather Vent Flat Sintered Mesh Pneumatic Cua Silencer Mufflers Solenoi ...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim caij ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

sintered ntxeem tau hlau hmoov bronze tso lim silencers haum suab nrov lim txo ...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim caij ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav -

HSP sintered stainless hlau 304/316L ntxeem tau lim tawm rau Environmental tiv thaiv, ...

Pneumatic Sintered Mufflers Lim siv cov ntxeem tau sintered bronze lim ntsiab ruaj ntseg rau cov qauv yeeb nkab fittings. Cov no compact thiab pheej yig mufflers ...

Saib nthuav dav

Lub ntsiab nta ntawm Sintered hlau lim

Sintered hlau lim muaj ntau yam tseem ceeb, suav nrog:

1. High filtration efficiency:

Sintered hlau lim muaj qhov me me me me thiab thaj chaw loj, uas tuaj yeem tshem tawm impurities hauv ntau yam roj thiab kua.

2. Kev sib xyaw tshuaj dav dav:

Cov ntxaij lim dej no yog tsim los ntawm cov ntaub ntawv uas muaj cov tshuaj tiv thaiv siab, ua rau lawv haum rau ntau yam corrosive media.

3. Kub kub kuj:

Sintered hlau lim tau zoo heev thermal stability, cia lawv ua hauj lwm zoo ntawm qhov kub thiab txias.

4. Durability:

Cov ntxaij lim dej no yog cov khoom siv ruaj khov, nrog lub zog ua haujlwm siab thiab ua haujlwm rau kev puas tsuaj, yaig thiab cuam tshuam.

5. Reusability:

Tsis zoo li cov lim dej pov tseg, sintered hlau lim tuaj yeem ntxuav thiab rov qab siv tau ntau zaus, ua rau lawv muaj txiaj ntsig zoo hauv cov ntawv thov pom.

Daim ntawv thov tshwj xeeb sintered hlau lim

Qhov tseeb tshwj xeeb lim ib txwm siv rau daim ntawv thov ib txwm, tsuas yog qee daim ntawv thov yuav siv

Nyob rau hauv qhov tshwj xeeb kub-kub heev,Siab-siab, siab heevCorrosive Production thiab

Kev sim ib puag ncig. Ib txhia xav tau kev tsim tshwj xeeb, yog li koj tuaj yeem tiv tauj

HENGKO los daws koj OEM hlau lim xav tau.

1. Kev lim dej

2. Fluidizing

4. Kev nthuav dav

6. Gas Lim

7. Khoom noj khoom haus thiab dej haus

Sintered hlau lim yog ntau yam thiab tuaj yeem siv rau ntau yam kev siv.

Qee yam kev siv ntawm sintered hlau lim yog:

1. Lim cov kua:

Sintered hlau lim tau siv dav hauv kev pom cov kua xws li dej, tshuaj, thiab cov kuab tshuaj.

Cov lim dej no muaj peev xwm tshem tawm cov khoom tsis zoo, impurities, thiab cov kab mob sib kis los ntawm cov kua, uas ua rau

lawv zoo tagnrho rau siv nyob rau hauv kws tshuaj, zaub mov thiab dej haus, thiab tshuaj industries.

Lawv kuj tseem siv rau hauv cov chaw kho dej khib nyiab kom tshem tawm cov pa phem thiab cov kab mob ntawm cov dej.

2. Lim ntawm Gases:

Sintered hlau lim kuj tseem siv rau hauv kev pom cov pa roj xws li cua, nkev roj, thiab lwm yam khoom siv roj.

Lawv tuaj yeem tshem tawm cov teeb meem me me, roj, thiab lwm yam impurities los ntawm cov pa roj, uas ua rau lawv haum rau siv hauv

kev lag luam thiab kev lag luam chaw xws li cov kav dej thiab cov tshuab cua compressed.

3. Catalytic Converters:

Sintered hlau lim yog siv nyob rau hauv catalytic converters kom tshem tawm cov pa phem los ntawm lub tsheb pa gases.

Lawv tuaj yeem ntxiab thiab lim tawm cov khoom me me, thaum tseem tso cai rau cov tshuaj tiv thaiv uas tshwm sim hauv catalytic.

converters coj qhov chaw. Qhov no yuav pab txo qis emissions ntawm tsheb thiab txhim kho huab cua zoo.

4. Fluidization:

sintered hlau lim yog siv nyob rau hauv cov txheej txheem fluidization, qhov twg lawv yog siv los faib roj los yog kua rau hauv ib lub txaj.

cov khoom tsis zoo. Cov qauv ntxeem tau ntawm sintered hlau lim tso cai rau txawm tias faib cov kua dej, uas yog qhov tseem ceeb rau

cov txheej txheem fluidization zoo.

5. Roj Lim:

Sintered hlau lim yog siv nyob rau hauv cov roj filtration systems kom tshem tawm impurities, contaminants, thiab particulate.

teeb meem los ntawm cov roj cav, roj hydraulic, thiab lwm yam roj muaj roj. Cov lim dej no muaj peev xwm tiv taus qhov kub thiab txias

thiab pressures, uas ua rau lawv zoo tagnrho rau siv nyob rau hauv industrial daim ntaub ntawv.

6. Cov Khoom Siv Kho Mob:

Sintered hlau lim yog siv nyob rau hauv cov khoom siv kho mob xws li nebulizers thiab tshuaj xa cov tshuab. Cov no

Cov lim dej muaj peev xwm lim tawm cov kab mob, cov kab mob, thiab lwm yam kab mob los ntawm cov tshuaj thiab cov pa tshuaj kho mob, uas

pab kom tus neeg mob muaj kev nyab xeeb.

7. Aerospace thiab Defense:

Sintered hlau lim yog siv nyob rau hauv aerospace thiab tiv thaiv kev lag luam rau ntau yam kev siv,

suav nrog roj pom, hydraulic kua lim, thiab huab cua thiab roj pom. Cov lim dej no yuav tsum ua tau raws li kev ua tau zoo thiab kev nyab xeeb

cov qauv, uas ua rau sintered hlau lim yog qhov kev xaiv zoo tshaj plaws rau cov kev lag luam no.

Engineer Solutions Support

Ntau xyoo dhau los, HENGKO tau daws cov teeb meem nyuaj heev thiab kev tswj xyuas cov ntaub ntawv hauv qhov dav

ntau yam kev lag luam thoob plaws ntiaj teb.Kev daws teeb meem engineering raws li koj daim ntawv thov yog peb lub hom phiaj thiab

Nws kuj yog peb lub hom phiaj ua kom koj cov khoom siv thiab cov haujlwm ua haujlwm zoo thiab ruaj khov raws li tau npaj tseg, Yog li

Vim li cas ho tsis peb ua hauj lwm hauv tes los ua kom tiav cov haujlwm no ua ke thiab kov yeej cov teeb meem, txhim kho

cov lim tshwj xeeb rau koj cov haujlwm tshwj xeeb hnub no.

Zoo siab txais tos los qhia koj qhov project thiab ua haujlwm nrog HENGKO, Peb yuav muab cov khoom zoo tshaj plaws hlau tshwj xeeb lim

Kev daws rau koj qhov project.

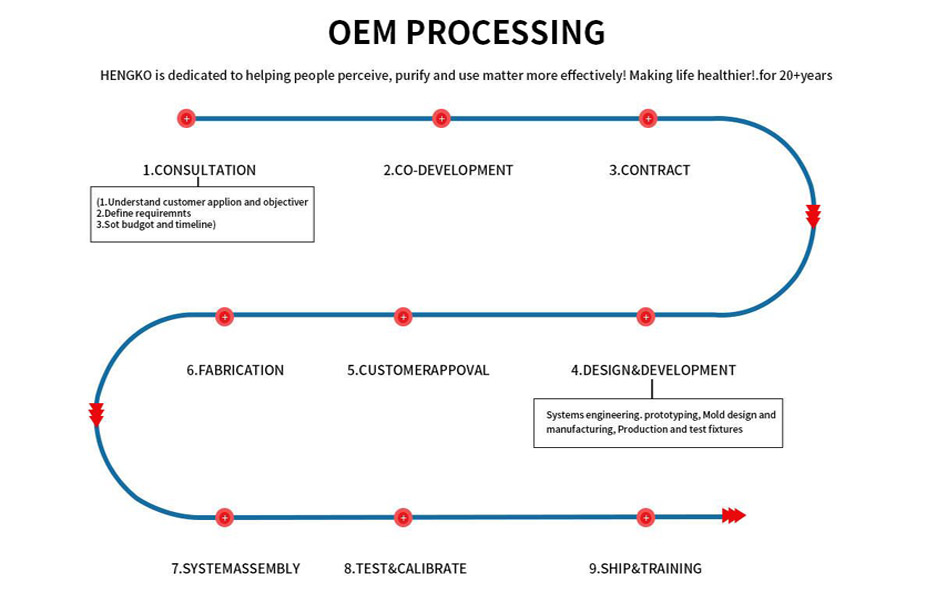

Kauj ruam los ntawm kauj ruam Qhia rau Customize Sintered Hlau Lim

Koj qhov zoo tshaj plaws tshwj xeeb lim tsim Hoobkas rau koj qhov tshwj xeeb siab xav tau tej yaam num, yog tias koj nrhiav tsis tau ib yam los yog zoo sib xws

Lim cov khoom, Txais toshu rau HENGKO ua hauj lwm ua ke los nrhiav kev daws teeb meem zoo tshaj plaws, thiab ntawm no yog cov txheej txheem ntawm

OEM tshwj xeeb lim,Thov Saib thiabTiv tauj pebtham kom ntxaws ntxiv.

HENGKO tau mob siab rau pab tib neeg pom, ntxuav thiab siv cov teeb meem zoo dua! Ua lub neej noj qab nyob zoo tshaj 20 xyoo.

1.Kev sab laj thiab tiv tauj HENGKO

2.Co-Development

3.Ua Daim Ntawv Cog Lus

4.Tsim & Txhim Kho

5.Customerappoval

6. Fabrication / Mass Production

7. Systemassembly

8. Test & Calibrate

9. Shipping & Kev cob qhia

Tseem Muaj Lus Nug Thiab Nyiam Paub Ntxiv Rau CovOEM Speical Lim, Thov koj xav tiv tauj peb tam sim no.

Kuj Koj Ua TauXa email rau pebDirectly Raws li:ka@hengko.com

Peb yuav xa rov qab nrog 24-teev, Ua tsaug rau koj tus neeg mob!

FAQ txog Sintered Hlau Lim:

1. Dab tsi yog sintered hlau lim?

A: Asintered hlau limyog ib lub lim ua los ntawm sintering hlau hmoov ua ke los ua ib tugkhoom ntxeem tau

uas tso cai rau cov kua los yog gases ntws los ntawm thaum ntxiab hais los yog impurities.

2. Dab tsi yog qhov txiaj ntsig ntawm kev siv sintered hlau lim?

Sintered hlau lim muab ib qho kev sib xyaw ua ke ntawm cov khoom uas ua rau lawv muaj txiaj ntsig zoo hauv ntau daim ntawv thov. Nov yog qee qhov txiaj ntsig tseem ceeb:

1. Lub zog thiab kav ntev:

Tsis zoo li daim ntawv los yog ntaub lim dej, sintered hlau lim yog qhov muaj zog heev thiab tuaj yeem tiv taus qhov kub thiab txias. Qhov no ua rau lawv zoo tagnrho rau kev thov kev lag luam xws li kev ua tshuaj lom neeg, petrochemical refining, thiab tsim hluav taws xob.

2. High porosity thiab meej pom:

Kev tswj porosity ntawm sintered hlau lim tso cai rau kev pom tseeb ntawm cov khoom mus rau qhov me me. Qhov no yog ua tiav los ntawm kev ua tib zoo tswj qhov loj thiab kev faib tawm ntawm cov pores thaum lub sij hawm sintering txheej txheem.

3. Corrosion kuj:

Ntau sintered hlau lim yog tsim los ntawm stainless hlau los yog lwm yam corrosion-resistant hlau, ua rau lawv haum rau siv nrog hnyav tshuaj thiab kua. Qhov no txo qhov kev xav tau ntawm kev hloov pauv thiab kev saib xyuas tas li.

4. Cleanability thiab reusability:

Tsis zoo li cov lim dej pov tseg, sintered hlau lim tuaj yeem ntxuav tau yooj yim thiab rov siv dua, ua rau lawv muaj txiaj ntsig zoo thiab kev xaiv ib puag ncig hauv lub sijhawm ntev.

5. High thermal poob siab tsis kam:

Sintered hlau lim tuaj yeem tiv taus kev hloov pauv sai hauv qhov kub thiab txias yam tsis muaj kev tawg lossis tawg, ua rau lawv haum rau siv nyob rau hauv qhov chaw kub kub xws li turbines thiab cav.

6. Versatility:

Sintered hlau lim tuaj yeem hloov kho kom tau raws li ntau qhov kev xav tau ntawm cov pore loj, cov duab, thiab cov khoom siv. Qhov no ua rau lawv hloov mus rau ntau yam kev siv thoob plaws kev lag luam sib txawv.

Nov yog qee qhov txiaj ntsig ntxiv tsim nyog hais txog:

* All-welded kev tsim kho:

sintered hlau lim muaj cov qauv seamless, tshem tawm qhov kev pheej hmoo ntawm cov dej xau cuam tshuam nrog cov kua nplaum los yog stitched lim.

* Lub neej ua haujlwm ntev:

Vim lawv cov durability thiab huv si, sintered hlau lim muaj lub neej ntev dua piv rau lwm hom lim.

* Biocompatibility:

Qee cov sintered hlau zoo li titanium yog biocompatible, ua rau lawv haum rau kev kho mob thiab tshuaj siv.

Zuag qhia tag nrho, cov txiaj ntsig ntawm kev siv cov ntxaij lim dej sintered ua rau lawv xaiv qhov kev xav tau rau cov ntawv thov uas ua haujlwm siab, ua haujlwm ntev, thiab rov siv dua yog qhov tseem ceeb.

3. Dab tsi yog qee qhov kev siv rau sintered hlau lim?

A: Sintered hlau lim tau siv ntau yam kev lag luam nrog rau cov khoom noj thiab dej haus,

tshuaj, tshuaj, petrochemical, dej kho thiab automotive.

Lawv feem ntau yog siv los lim cov kua lossis roj xws li roj, roj, roj lossis dej.

4. Dab tsi yuav tsum tau them sai sai rau thaum xaiv lub chaw tsim khoom sintered hlau lim?

A: Thaum xaiv cov chaw tsim khoom sintered hlau lim, nrhiav lub tuam txhab uas muaj kev paub dhau los thiab kev txawj ntse hauv

tsim cov lim dej zoo, siv cov txheej txheem tsim khoom siab heev thiab cov thev naus laus zis, muaj kev hloov kho

kev xaiv thiab kev txhawb nqa, thiab muaj lub koob npe nrov rau cov neeg siv khoom thiab xa khoom Ib lub tuam txhab nrog lub koob npe zoo.

5. Yuav ua li cas sintered hlau lim?

sintered hlau lim yog tsim los ntawm ib tug fascinating txheej txheem uas yuav transforming hlau hmoov rau hauv ib tug muaj zog, ntxeem tau qauv. Ntawm no yog ib tug step-by-step breakdown:

1. Hlau hmoov npaj:

Txoj kev taug kev pib nrog cov hmoov hlau, feem ntau yog ua los ntawm cov hlau tsis muaj steel, bronze, npib tsib xee, lossis txawm tias titanium. Cov hmoov no tuaj yeem tau txais los ntawm ntau txoj hauv kev xws li kev sib tsoo, atomization, lossis txawm tias cov tshuaj decomposition.

2. Sib tov thiab shaping:

Cov hmoov hlau yog tov nrog binders thiab lubricants los txhim kho nws cov ndlwg thiab nias yam ntxwv. Qhov sib tov no ces nias rau hauv cov duab uas xav tau ntawm cov khoom lim siv lub siab siab tuag. Cov duab tuaj yeem yog cov discs yooj yim, cov raj tsis yooj yim, lossis txawm tias qhov sib txawv geometry nyob ntawm daim ntawv thov.

3. Sintering:

Qhov no yog lub plawv ntawm cov txheej txheem uas cov khawv koob tshwm sim. Cov duab nias yog rhuab nyob rau hauv ib qho chaw tswj ntawm qhov kub thiab txias hauv qab lub melting point ntawm hlau. Qhov cua sov no ua rau cov khoom hlau sib txuas ua ke ntawm lawv cov ntsiab lus sib cuag, tsim kom muaj zog, sib cuam tshuam network thaum tseem tawm hauv qhov chaw txaus rau lub lim lub porosity.

4. Tiav thiab tu:

Thaum sintered, cov khoom lim tau dhau los ua cov txheej txheem ntxiv xws li cua txias, de-binding (tshem tawm cov neeg ua haujlwm khi), thiab ua kom tiav. Qee cov ntxaij lim dej yuav xav tau kev ua haujlwm ntxiv lossis sib dhos kom ua tiav daim ntawv xav tau kawg.

5. Kev tswj xyuas zoo thiab kev sim:

Cov theem kawg suav nrog kev tswj xyuas nruj kom ntseeg tau tias cov lim tau raws li qhov xav tau tshwj xeeb rau porosity, pore loj faib, lub zog, thiab lwm yam. Qhov no feem ntau suav nrog kev tshuaj xyuas qhov muag, ntsuas qhov ntev, thiab txawm tias kev ntsuas kev ua haujlwm nrog cov kua dej.

Thiab voila! Cov hmoov hlau txo qis tau hloov mus rau hauv lub zog, rov siv tau cov lim dej npaj txhij los daws ntau yam haujlwm pom thoob plaws kev lag luam.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias muaj kev hloov pauv hauv cov txheej txheem tseeb nyob ntawm seb hom hlau, cov khoom xav tau, thiab cov chaw tsim khoom tshwj xeeb. Qee cov txheej txheem suav nrog kev siv cov hlau ua ntej ua ntej siv cov hmoov, lossis siv cov cua kub sib txawv xws li microwave sintering.

Nyob rau hauv ib lub ntsiab lus, cov txheej txheem sintering tsim cov qauv hlau uas muaj zog tsis tau ntxeem tau zoo lim dej thaum tuav cov khoom tsim nyog xws li kub thiab siab ua haujlwm. Qhov no ua rau sintered hlau lim cov cuab yeej tseem ceeb hauv ntau qhov chaw, los ntawm cov khoom siv kho mob mus rau kev tsim kho tsheb.

6. Dab tsi yog cov ntaub ntawv siv los ua sintered hlau lim?

A: Sintered hlau lim tuaj yeem tsim los ntawm ntau yam khoom xws li stainless hlau, tooj liab, npib tsib xee, titanium.

thiab lwm yam alloys. Qhov kev xaiv ntawm cov khoom yog nyob ntawm daim ntawv thov tshwj xeeb thiab cov khoom xav tau ntawm lub lim.

7. Puas tuaj yeem sintered hlau lim tau customized?

A: Yog, sintered hlau lim tuaj yeem ua raws li cov kev xav tau tshwj xeeb ntawm cov ntawv thov sib txawv. Cov neeg tsim khoom

tuaj yeem kho qhov pore loj, tuab, cov duab thiab lwm yam tsis zoo los ua kom pom kev ua haujlwm zoo.

8. Kuv yuav ua li cas ntxuav thiab tswj cov sintered hlau lim?

A: Sintered hlau lim tuaj yeem ntxuav los ntawm kev rov qab ntxuav nrog dej los yog cua compressed lossis los ntawm immersion hauv ib

tshuaj ntxuav. Nws yog ib qho tseem ceeb uas yuav tau ua raws li cov chaw tsim tshuaj paus kev tu thiab tu cov lus pom zoo rau

xyuas kom zoo lim kev ua tau zoo thiab kev pab lub neej.