-

Resistant Kub Kub Stainless Hlau Sintered Powder Filter Element lim cartridg ...

Khoom Piav Qhia Sintered hmoov lim caij tseem hu ua hlau ntxeem tau sintered lim yog ua los ntawm titanium los yog stainless hlau hmoov. Nws yog ib tug tshiab style ntawm m ...

Saib nthuav dav -

Sintered Cartridge Lim rau Polysilicon

Sintered cartridge lim rau polysilicon ntau lawm HENGKO sintered hlau lim muab huab cua huv, uas ua rau tib neeg txoj kev noj qab haus huv, tiv thaiv kev thuam ...

Saib nthuav dav -

Acid thiab Alkali Resistant Ntau 316L Porous Stainless Hlau Lim Sintered Filt ...

Khoom Piav Qhia HENGKO biomedical lim yog ua los ntawm 316L hlau hmoov sintered ntawm qhov kub thiab txias, nrog ib tug uniform porosity ntawm 0.2-0.5 um, corrosion resistance...

Saib nthuav dav -

20 Micron 316 Stainless Hlau Hlau Mesh Lim Cartridge Inner Core 32mm Ntev M4 Xov

Hlau mesh lim yog hlau mesh uas yog stretched los ntawm kev siv hlau threads, nrog zoo qhib ntawm txawv hlau threads. Thaum cov dej tsis huv yog lub twj tso kua...

Saib nthuav dav -

Rov qab Osmosis Stainless Hlau Lim Dej Lim Purifier Pom Qhov System SS 316 M ...

Rov qab Osmosis Stainless Hlau Lim Dej Lim Purifier Lim System SS 316 Mesh Cartridge Lim Cov Khoom Muag Txhua tus tab tom nrhiav n...

Saib nthuav dav -

Sintered Stainless Hlau Lim Cartridges rau Kev Tsim Tshuaj Txheej Txheem Pom

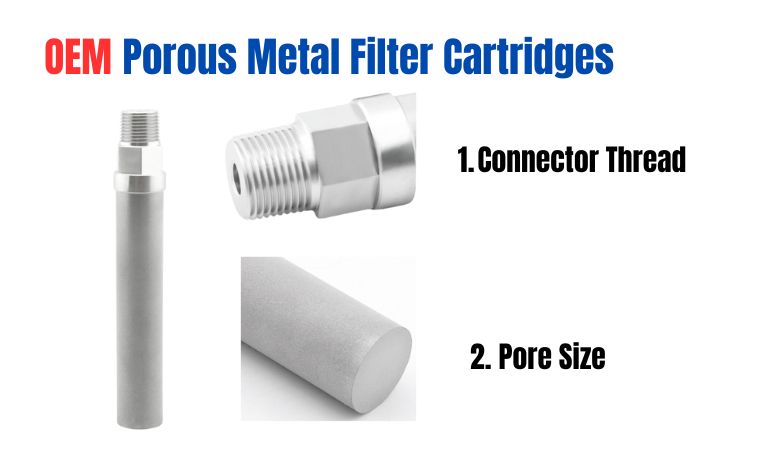

Porous sinter hlau cartridges, feem ntau nrog customized connectors (Qee lub sij hawm connectors tsis ntxiv nyob rau hauv tej daim ntawv thov scenarios), yog siv los cais ...

Saib nthuav dav -

HENGKO Sintered Filter Cartridge rau Cov Txheej Txheem Roj thiab Kev Ntsuam Xyuas On-Line

Gas thiab Sample Filtration Rau cov txheej txheem Gas thiab On-Line Analysis Kev pom cov pa roj yog qhov tseem ceeb hauv ntau yam kev siv, tsis tau tsuas yog peb m ...

Saib nthuav dav -

Catalyst ntxeem tau hlau lim huab ib puag ncig ua haujlwm Gas Sample Probe, siab ntws fi ...

Gas thiab kua qauv analyzer lim tiv thaiv cov tshuaj ntsuam xyuas los ntawm cov qauv impurities los ntawm kev tshem cov av thiab cov kua los ntawm cov pa roj nrog 99.99999 +% efficiency ntawm 0.1 m ...

Saib nthuav dav -

316L Sintered stainless hlau lim cartridge rau roj sib cais

Cov tshuab lim siv sintered hlau lim cov ntsiab lus tau ua pov thawj los ua ib qho txiaj ntsig thiab kev lag luam rau lwm cov khoom sib cais susceptib ...

Saib nthuav dav -

Hloov sintered micron ntxeem tau hlau stainless hlau lim cartridges rau roj / o ...

Stainless hlau sintered lim yog tsim los ntawm cov raj, lub tog raj kheej, cartridges, khob nrog flange, xov, thiab fasteners, thiab lwm yam ... Nruab rau hauv cov kav dej ...

Saib nthuav dav -

5 10 micron stainless hlau 316L sintered lim cartridge / lub tog raj kheej

HENGKO muaj ntau yam ntxeem tau hlau cartridge lim los yog kev cai-tsim cov kev pab cuam rau pom pom nyob rau hauv cov ntaub ntawv tseem ceeb (yuam lub ceev ceev ...

Saib nthuav dav -

Sintered lim cartridge zoo lav txias kos seamless stainless hlau lim ...

Khoom Piav Qhia HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm kub....

Saib nthuav dav -

Sintered hlau hmoov stainless hlau 316L muaj plua plav collector cua lim cartridge

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

0.5 5 10 micron lim sintered lim cartridge rau cov hlau lead-dawb reflow qhov cub

Ib daim thaiv nitrogen nyob rau hauv thaj tsam ntawm lub dav hlau soldering, nrog rau thawj nitrogen dispersion raj muab nyob rau hauv pem hauv ntej ntawm thawj nozzle ntawm lub dav hlau ...

Saib nthuav dav -

Kev cai stainless hlau 316L nitrogen sintered lim cartridge rau Lead-dawb reflow ove ...

HENGKO muaj nitrogen gas soldering daim ntawv thov kev daws teeb meem rau reflow thiab yoj soldering, daws cov teeb meem loj ntsib los ntawm cov khoom siv hluav taws xob thiab ...

Saib nthuav dav -

Microporous sintered hlau hmoov stainless hlau ss 304 316L lim cartridge

HENGKO stainless hlau lim cartridges raug pom zoo rau chav ua haujlwm thiab zoo haum rau cov kua lossis roj siv nrog rau cov kuab tshuaj, tshuaj lom neeg ...

Saib nthuav dav -

txawj hmoov sintered micron hlau bronze 316 stainless hlau natural gas lim laub ...

Stainless hlau cartridge lim orifices yog crisscrossed thiab resistant rau high kub thiab ceev txias thiab kub. Resistant rau corrosion. Haum rau ib ...

Saib nthuav dav -

Kev cai sintered stainless hlau 316L hlau resists siab kub cua lim lub tog raj kheej ...

Khoom Piav Qhia HENGKO stainless hlau lim ntsiab yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau hlau mesh nyob rau hauv high temperatur ...

Saib nthuav dav -

30-45/50-60um ntxeem tau stainless hlau sintered hlau lim cartridge rau nplaim ntes

Cov nplaim taws yog ib qho khoom siv haum rau qhov qhib ntawm lub qhov rooj, lossis rau qhov sib txuas ntawm cov kav dej hauv lub kaw lus. Lawv tso gases los yog vapors rau f ...

Saib nthuav dav -

micron ntxeem tau hmoov sintered hlau stainless hlau lim cartridges

sintered hlau lim thiab porous hlab yog ntev, cylindrical lim nrog nyias phab ntsa, piv txwv li lawv muaj ib tug siab ntev-rau-inch ratio. Qhov ntxeem tau hlau lim...

Saib nthuav dav

Porous Sintered Hlau Lim siv rau dab tsi?

Porous sintered hlau lim yog muaj ntau yam thiab nrhiav kev siv thoob plaws ntau yam kev lag luam

vim lawv cov kav ntev, tsis kam mus rau qhov kub thiab txias, thiab muaj peev xwm tiv taus

corrosive ib puag ncig. Nov yog qee qhov kev siv rau cov lim dej no:

1. Kev siv lim:

* Roj lim:

2. Catalyst rov qab:

Hauv cov tshuaj reactors, sintered hlau lim yog siv los rov qab cov catalysts kim siv hauv cov txheej txheem tshuaj tiv thaiv.

3. Sparging thiab Gas Diffusion:

Cov lim dej no yog siv rau hauv bioreactors thiab cov txheej txheem fermentation los qhia cov pa roj rau hauv cov kua hauv kev tswj hwm,

4. Kev siv cua tshuab:

Hauv automotive thiab aerospace industries, sintered hlau vents tiv thaiv cov cuab yeej rhiab los ntawm kev sib npaug ntawm kev sib npaug

5. Fluidization:

Siv nyob rau hauv hmoov tuav industries kom fluidize bulk hmoov, xyuas kom meej txaus thiab tiv thaiv clogging

6. Aerosol Sampling:

sintered hlau lim yog siv nyob rau hauv ib puag ncig xyuas cov cuab yeej los sau cov qauv aerosol rau kev tsom xam,

7. Thaum tshav kub kub Exchanger:

Vim lawv cov thermal conductivity thiab tsis kam mus rau qhov kub thiab txias, cov ntxaij lim dej no kuj siv rau hauv

Cov yam ntxwv tseem ceeb ntawm Porous Hlau Lim Cartridges:

1. Cov khoom xyaw

Porous hlau lim feem ntau yog tsim los ntawm sintered hlau xws li stainless hlau (304, 316L),

titanium, thiab lwm yam alloys xws li Hastelloy thiab Inconel. Qhov no muaj pes tsawg leeg muab zoo heev

mechanical zog thiab tsis kam mus corrosion thiab thermal shock.

2. Tswj Porosity

Cov txheej txheem tsim khoom tso cai rau kev tswj hwm qhov pore loj, xws li 0.5 txog 200 microns.

Qhov kev tswj no ua kom yooj yim pom cov khoom ntawm ntau theem, ua rau lawv haum rau microfiltration

ntawm gases thiab kua nyob rau hauv lub siab thiab kub tej yam kev mob.

3. Muaj zog thiab kav ntev

Cov lim dej no tuaj yeem tiv taus qhov sib txawv siab (txog 3000 psi) thiab ua haujlwm hnyav,

kom ntseeg tau lub neej ntev kev pab cuam thiab kev cia siab rau hauv kev thov kev thov.

4. Cleanability thiab Reusability

Porous hlau lim cartridges yog tsim los ntxuav thiab rov siv dua, feem ntau los ntawm txoj kev nyiam

backflushing los yog ultrasonic tu. Qhov no feature tsis tsuas yog txo cov nqi khiav hauj lwm tab sis kuj

txhim kho lawv lub neej ntev.

5. Thermal thiab chemical Resistance

Cov lim dej no tswj kev ua haujlwm hauv qhov kub thiab txias (txog 930 ° C) thiab tiv taus ntau yam

ntawm chemicals, ua rau lawv zoo tagnrho rau kev siv tshuaj, tshuaj, thiab zaub mov thiab

dej haus kev lag luam.

6. Customization Options

Cov neeg tsim khoom muab kev hloov kho raws li cov khoom siv, qhov pore loj, thiab qhov ntev kom tau raws li qhov tshwj xeeb

cov cai thov.

Qhov kev hloov pauv no tso cai rau kev ua haujlwm zoo raws li qhov xav tau ntawm kev lag luam sib txawv.

7. Tsis tshua muaj siab poob

Cov qauv tsim ntawm cov ntxaij lim dej ntxeem tau ua kom lub siab poob qis thoob plaws lub lim nruab nrab, uas txhim kho

ntws tus nqi thiab tag nrho system efficiency thaum txo qis zog noj.

8. Kev siv ntau yam

Cov lim dej no yog siv rau hauv ntau qhov chaw, suav nrog aerospace, tsheb, roj thiab roj, thiab lub zog.

tiam, rau daim ntaub ntawv xws li pom, khiav tswj, thiab txo suab nrov.

Hauv cov ntsiab lus, porous hlau lim cartridges yog tsim los rau kev ua haujlwm siab thiab ntau yam, ua

lawv cov khoom tseem ceeb hauv ntau lub tshuab lim dej.

Lawv cov kev tsim kho muaj zog thiab muaj peev xwm ua tau raws li cov ntawv thov tshwj xeeb kom ntseeg tau tias lawv ua tau raws li

nruj kev xav tau ntawm cov txheej txheem tsim khoom niaj hnub.

Hom Porous Hlau Lim Cartridges

Porous hlau lim cartridges yog dav siv nyob rau hauv ntau yam lag luam vim lawv zoo heev pom zog,

durability, thiab tshuaj tiv thaiv. Lawv feem ntau yog tsim los ntawm sintered hlau hmoov, xws li

stainless hlau, bronze, los yog npib tsib xee.

Nov yog qee hom kev ntxeem tau hlau lim cartridges:

1.Raws li Pore Loj:

* Coarse:Qhov loj dua qhov pore, haum rau tshem tawm cov khoom loj dua li av, xuab zeb, thiab khib nyiab.

* Zoo:Cov pore me me, zoo tagnrho rau tshem tawm cov khoom zoo li cov kab mob, kab mob, thiab colloids.

* Ultrafine:Cov pore me me heev, siv rau kev siv ultra-filtration, xws li tshem tawm cov khib nyiab thiab impurities.

2. Raws li Cov Qauv:

* Cylindrical:Cov duab zoo tshaj plaws, muab thaj chaw loj rau kev pom.

* Pleated:Folded los yog pleated tsim, ua kom pom qhov chaw thiab txhim kho kev ua haujlwm.

* Disc:Pav ca, disc-shaped cartridges, haum rau cov kev siv tshwj xeeb lossis cov khoom siv.

3. Raws li cov khoom siv:

* Stainless hlau:Cov khoom siv feem ntau vim nws zoo heev corrosion kuj, lub zog, thiab siab-kub kam rau ua.

* Bronze:Muaj kev tiv thaiv corrosion zoo thiab thermal conductivity, feem ntau siv rau hauv kev siv hluav taws xob sib pauv.

* Nickel:Muab cov tshuaj tiv thaiv zoo heev thiab kev ua haujlwm kub, haum rau qhov chaw hnyav.

* Lwm yam hlau:Raws li cov kev cai tshwj xeeb, lwm yam hlau xws li titanium, aluminium, lossis tungsten tuaj yeem siv.

4. Raws li kev lim tshuab:

* Qhov tob lim:Particles yog daig nyob rau hauv lub porous qauv ntawm lub lim.

* Nto lim:Cov khoom raug ntes rau ntawm qhov chaw lim.

* Sieve Lim:Cov khoom yog lub cev thaiv los ntawm qhov pore loj.

Cov ntsiab lus tseem ceeb uas yuav tsum tau xav txog thaum xaiv lub tshuab lim hlau ntxeem tau:

* Particle Loj:Qhov loj ntawm cov khoom yuav raug tshem tawm.

* Tus nqi ntws:Qhov yuav tsum tau ntws tus nqi los ntawm lub lim.

* Kev Poob Siab:Qhov tso cai siab poob hla lub lim.

* Tshuaj Compatibility:Kev sib raug zoo ntawm cov khoom siv lim dej nrog cov kua uas tau lim.

* Kub:Kev khiav hauj lwm kub ntawm lub lim.

* Ntxuav thiab rov tsim dua tshiab:Txoj kev thiab zaus ntawm kev ntxuav lossis rov tsim cov lim dej.

Los ntawm kev nkag siab txog ntau hom thiab yam tseem ceeb no, koj tuaj yeem xaiv qhov tsim nyog tshaj plaws porous hlau lim cartridge rau koj cov kev xav tau tshwj xeeb.

Yuav Ua Li Cas Xaiv Txoj Cai Porous Hlau Lim Cartridges?

Muaj ntau yam uas koj yuav tsum xav txog thaum xaiv txoj cai porous hlau lim cartridges

rau kojlim khoom lossis qhov project. Ntawm no peb sau 8 lub ntsiab lus tseem ceeb uas koj yuav tsum kuaj xyuas.

1. Particle Loj:

* Txiav txim siab qhov loj ntawm qhov koj xav tau tshem tawm.

* Xaiv lub cartridge nrog lub pore loj uas me dua li cov khoom yuav tsum tau lim.

2. Tus nqi ntws:

* Xav txog qhov yuav tsum tau khiav ntawm lub lim.

* Xaiv lub cartridge nrog thaj tsam ntawm qhov chaw thiab qhov pore loj uas tuaj yeem tswj tau qhov xav tau txaus

tsis muaj kev poob siab ntau dhau.

3. Siab poob:

* Ntsuam xyuas qhov tso cai poob siab hla lub lim.

* Xaiv lub cartridge nrog lub siab poob qis kom txo qis kev siv hluav taws xob thiab ua kom muaj kev ua haujlwm zoo.

4. Tshuaj Compatibility:

* Txheeb xyuas cov tshuaj sib xyaw ua ke ntawm cov khoom siv lim dej nrog cov kua dej lim.

* Xaiv lub cartridge ua los ntawm cov khoom uas tiv taus corrosion thiab tshuaj lom neeg los ntawm cov kua.

5. Kub:

* Txiav txim siab qhov ntsuas kub ntawm lub lim.

* Xaiv lub cartridge uas tuaj yeem tiv taus qhov ntsuas kub uas xav tau yam tsis muaj kev cuam tshuam nws qhov kev ua tau zoo lossis kev ncaj ncees.

6. Kev ntxuav thiab rov tsim dua tshiab:

* Xav txog txoj kev thiab zaus ntawm kev tu lossis rov tsim cov lim dej.

* Xaiv lub cartridge uas yooj yim los ntxuav lossis rov tsim dua tshiab, nyob ntawm daim ntawv thov tshwj xeeb thiab kev tu kom huv.

7. Lim Media:

* Ntsuam xyuas hom lim xov xwm siv hauv daim cartridge.

* Xav txog cov kev xaiv xws li sintered hlau hmoov, woven hlau mesh, los yog lwm yam ntaub ntawv ntxeem tau, raws li koj cov kev xav tau tshwj xeeb.

8. Cartridge Tsim:

* Ntsuas cov qauv tsim, xws li cylindrical, pleated, lossis disc-shaped.

* Xaiv tus qauv tsim uas sib haum nrog koj cov cuab yeej siv thiab muab cov kev pom zoo uas xav tau.

9. Chaw tsim tshuaj paus thiab zoo:

* Tshawb nrhiav cov tuam txhab muaj npe nrov ntawm cov hlau ntxeem tau lim cartridges.

* Xaiv lub cartridge los ntawm cov chaw tsim khoom nrog cov ntaub ntawv pov thawj ntawm qhov zoo thiab kev ntseeg siab.

FAQ

1. Dab tsi yog cov hlau nplaum lim cartridges thiab lawv ua haujlwm li cas?

Porous hlau lim cartridges yog cov khoom siv pom ua los ntawm cov hlau sintered uas muaj cov qauv nruj, ntxeem tau.

Cov cartridges no feem ntau yog tsim los ntawm compacting hlau hmoov nyob rau hauv qhov kub thiab txias siab los tsim ib qho khoom,

tseem ntxeem tau, khoom siv. Lub porosity tuaj yeem tswj tau meej rau lub hom phiaj tshwj xeeb particle loj.

Raws li cov kua los yog gases dhau los ntawm lub lim, cov khoom loj dua li qhov pore loj raug kaw, tshem tawm cov kwj tawm kom zoo.

Cov txheej txheem no yog qhov tseem ceeb rau cov ntawv thov uas xav tau siab purity thiab efficiency, xws li hauv kev tsim tshuaj,

chemical processing, thiab cov txheej txheem tswj cov kua dej tseem ceeb.

2. Cov ntaub ntawv dab tsi uas feem ntau siv rau hauv kev tsim cov kua nplaum hlau lim cartridges?

Cov khoom siv feem ntau siv los ua cov hlau ntxeem tau zoo xws li stainless hlau, titanium, thiab npib tsib xee alloys.

Cov ntaub ntawv no raug xaiv rau lawv cov khoom siv dag zog, zoo heev corrosion kuj, thiab muaj peev xwm tiv taus huab cua

qhov kub thiab txias. Stainless hlau yog dav nyiam rau kev siv dav siv vim nws cov kav ntev thiab cov nqi-zoo,

thaum titanium thiab npib tsib xee alloys nyiam nyob rau hauv ib puag ncig uas muaj corrosive heev los yog xav tau ntau zog-rau-qhov hnyav piv.

3. Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm kev siv lub tshuab lim hlau ntxeem tau tshaj lwm hom lim dej?

Porous hlau lim cartridges muaj ntau yam zoo:

* Siab kub ua hauj: Lawv tuaj yeem ua haujlwm tau zoo nyob rau hauv qhov kub thiab txias, uas yog qhov tseem ceeb rau cov txheej txheem xws li cov pa kub lim thiab catalysis.

* Tshuaj tiv thaiv: Hlau lim yog inert rau feem ntau chemicals, ua rau lawv haum rau hnyav tshuaj ib puag ncig uas polymer lim yuav degrade.

* Lub zog thiab kav ntev: Cov ntxaij lim dej hlau tuaj yeem tiv taus kev kub ntxhov thiab kev ntxhov siab ntawm cov neeg kho tshuab tsis muaj deforming lossis tawg.

* Regenerable thiab Reusable: Lawv tuaj yeem ntxuav thiab rov siv tau ntau zaus, muab lub neej ua haujlwm ntev thiab txo cov nqi hloov pauv thiab pov tseg.

* Customizable: Lub porosity thiab geometric tsim tuaj yeem hloov kho kom tau raws li cov kev xav tau tshwj xeeb pom, muab kev yooj yim hla ntau yam kev siv.

4. Nyob rau hauv dab tsi daim ntaub ntawv yog porous hlau lim cartridges feem ntau siv?

Porous hlau lim cartridges tau siv dav hauv ntau daim ntawv thov tseem ceeb, suav nrog:

* Kev lag luam tshuaj: Rau kev pom ntawm cov tshuaj purity siab thiab kev tiv thaiv cov txaj catalyst los ntawm cov kab mob sib kis.

* Pharmaceuticals: Hauv kev tsim cov APIs (Active Pharmaceutical Ingredients) uas tswj kev sib kis yog qhov tseem ceeb.

* Khoom noj khoom haus thiab dej haus: Rau cov txheej txheem sterile filtration los xyuas kom meej cov khoom muaj kev ruaj ntseg thiab zoo.

* Roj thiab Roj: Nyob rau hauv cov dej ntws thiab downstream ua kom tshem tawm cov khoom ntawm cov roj thiab tiv thaiv cov cuab yeej rhiab.

* Aerospace thiab Automotive: Rau kev lim dej hydraulic thiab roj nyob rau hauv kev ua haujlwm hnyav.

5. Yuav ua li cas porous hlau lim cartridges tswj thiab ntxuav?

Kev saib xyuas thiab tu cov ntxeem tau hlau lim cartridges nyob ntawm ntau yam ntawm kev sib kis thiab lub cev

cov khoom ntawm cov khoom lim. Cov txheej txheem tu vaj tse muaj xws li:

* Kev rov qab los: Rov qab cov kev taw qhia ntws kom tshem tawm cov khoom.

* Ultrasonic tu: Siv cov suab nrov nthwv dej kom tshem tawm cov khoom zoo.

* Tshuaj ntxuav: Siv cov kuab tshuaj los yog cov kua qaub kom yaj cov kab mob.

* Kub kub Burnout: Siv cua sov los oxidize cov ntaub ntawv organic.

Kev tu thiab tu kom zoo tuaj yeem txuas ntxiv lub neej ntawm cov lim cartridges, ua rau lawv muaj txiaj ntsig zoo hauv ntau daim ntawv thov kev lag luam.