-

Biopharmaceutical purification thiab pom ntxeem tau lim phaj 10um 20um 50um

Lub porous lim phaj yog ib yam tshiab ntawm high-efficiency porous lim khoom ua los ntawm hlau stainless hlau hmoov los ntawm hmoov sieving, molding, sinterin ...

Saib nthuav dav -

Sintered Copper Bronze Grounding Phaj

Deters Electrolysis thiab Galvanic CorrosionReduces RF cuam tshuam thiab txhim kho Electronics Performance Zoo txais tos rau koj cov khoom siv GPS, huab cua ...

Saib nthuav dav -

sintered hlau puag ncig qhov tob lim nplooj ntawv rau cannabis roj ntau lawm

Filtration Hauv kev tsim cov khoom lag luam cannabinoid ruaj khov yog qhov tseem ceeb. Txhawm rau tshem tawm cov waxes, rog thiab roj los ntawm winterization ntau ...

Saib nthuav dav -

Stainless hlau ntxeem tau hlau Sheets SS316 Lim rau Hydrogen Gas Diffusion

Stainless hlau ntxeem tau hlau Sheets SS316 Lim rau Hydrogen Gas Diffusion Xauv lub Versatility ntawm Sintered Hlau Elements nrog HENGKO! Peb sintered meta ...

Saib nthuav dav -

Gas Diffusion Layers Sheet rau MEAs, stainless hlau ntxeem tau hlau sintered / hlau mesh ...

HENGKO stainless hlau lim daim hlau yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau ...

Saib nthuav dav -

Multi-layer sintered stainless hlau mesh phaj fluidized txaj khoom Distributor bot ...

Stainless hlau mesh phaj rau kua txaj Tswj kev faib roj, hmoov khoom kis tau tus mob, thiab ua haujlwm fluidization tau dav siv hauv indu ...

Saib nthuav dav -

316 304 stainless hlau phaj - Sintered ntxeem tau hlau lim alien media

HENGKO stainless hlau phaj lim yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau hlau mesh ntawm qhov kub thiab txias. Lawv tau ...

Saib nthuav dav -

Corrosion resistant microns 316L stainless hlau ntxeem tau sintered lim hlau los xij / ...

Khoom Piav Qhia HENGKO ntxeem tau hlau roj diffusion khaubncaws sab nraud povtseg yog cov kev xaiv rau kev ua tau zoo electrolyzer thiab roj cell daim ntaub ntawv. Uniform cov...

Saib nthuav dav -

Ib qho yooj yim huv Micron ntxeem tau SUS Sintered 316L Stainless Hlau Inline Hlau Sheet Phaj Rou ...

Cov sintered ntxeem tau hlau los xij uas muaj porosity siab tau los ntawm cov hmoov hlau los ntawm kev sib kis dawb ua raws li sintering. Qhov sintered struc...

Saib nthuav dav -

0.2 5 10 40 Micron ntxeem tau sintered hmoov stainless hlau 316L hlau phaj lim rau c ...

Cov ntaub ntawv ntxeem tau sintered daim hlau tau nyob rau hauv cov khaubncaws sab nraud povtseg los ntawm kev sib kis dawb, compaction, thiab sintering metallic hmoov yog siv los ua ib qho khoom lag luam kom tau txais fi ...

Saib nthuav dav -

Customized 2 10 20 60 Micron Porous Sintered Stainless Hlau 316L Hlau Phaj Lim

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj menyuam-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

5 10 30 60 90 microns hmoov micro ntxeem tau sintered hlau ntawv lim

Sintered hlau lim ntawv yog dav siv los tshem tawm cov khoom txawv teb chaws los ntawm ntau yam sib txawv ntawm cov xov xwm ntws. Daim ntawv thov loj: General gases, ...

Saib nthuav dav -

HENGKO sintered stainless hlau 316 ntxeem tau hlau roj diffusion txheej lim ntawv rau ...

HENGKO stainless hlau sintered hlau mesh lim phaj yog tsim los ntawm ntau txheej txheej woven hlau mesh vaj huam sib luag ua ke siv cov txheej txheem sintering. Cov txheej txheem no ...

Saib nthuav dav -

Kev kho mob qib micron stainless hlau 316 316L hlau mesh ntau txheej phaj / disc lim ...

HENGKO sintered hlau mesh cov ntxaij lim dej muaj 5 sintered hlau mesh txheej nrog kev txhawb nqa tus kheej rau kev siv tshuab siab thiab kub-resistant ...

Saib nthuav dav -

Uniform lub zog sintered ntxeem tau hlau micron lim fluidizers bronze tooj dag tooj liab fil ...

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj menyuam-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

Flow tswj thiab kua faib sintered lim phaj / ntawv, hmoov sintered ntxeem tau ...

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj menyuam-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

Porous hlau sintered ntxeem tau bronze lim daim hlau / ntawv rau ntws thiab suab tswj

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj menyuam-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

porous hlau lim disc square strainer micron sintered bronze lim ntawv

HENGKO tsim cov khoom lim hauv ntau yam khoom, qhov ntau thiab tsawg, thiab fittings kom lawv tau yooj yim teev nrog cov yam ntxwv thiab configura ...

Saib nthuav dav -

Hepa sintered bronze stainless hlau ntxeem tau hlau lim ntawv rau huab cua / roj lim tshuab

HENGKO tsim cov khoom lim hauv ntau yam khoom, qhov ntau thiab tsawg, thiab fittings kom lawv tau yooj yim teev nrog cov yam ntxwv thiab configura ...

Saib nthuav dav -

Kev cai sintered hmoov hlau fitler ntawv microns porosity bronze lim ntawv rau wat ...

HENGKO tsim cov khoom lim hauv ntau yam khoom, qhov ntau thiab tsawg, thiab fittings kom lawv tau yooj yim teev nrog cov yam ntxwv thiab configura ...

Saib nthuav dav

Cov yam ntxwv tseem ceeb ntawm Porous Hlau Phaj:

Cov yam ntxwv tseem ceeb ntawm cov ntawv hlau ntxeem tau muaj xws li:

1.High Durability:

Cov ntawv hlau ntxeem tau yog tsim los ntawm cov ntaub ntawv muaj zog xws li stainless hlau, titanium, lossis npib tsib xee alloys,

muab cov cuab yeej zoo heev thiab ua haujlwm rau corrosion, hnav, thiab kub kub.

| Khoom siv | Mechanical Strength | Corrosion Resistance | Hnav Resistance | Kub Resistance | Daim ntawv thov |

|---|---|---|---|---|---|

| Stainless hlau | Siab | Siab | Siab | Zoo heev (txog 800 ° C) | Lim, tshuaj ua haujlwm, roj & roj, tshuaj |

| Titanium | Nruab nrab | Siab heev | Nruab nrab | Zoo heev (txog 600 ° C) | Aerospace, marine ib puag ncig, kev siv kho mob |

| Nickel alloys | Siab heev | Zoo heev | Siab | Superior (txog 1000 ° C) | High-temperature filtration, chemical processing, fais fab tuag |

2.Txoj kev lim dej:

Kev tswj qhov pore loj thiab kev faib tawm tsis sib xws tso cai rau kev pom tseeb, muab qhov sib xws

kev ua tau zoo thoob plaws ntau yam kev siv.

3.Customizable Porosity:

Porous hlau los xij tuaj yeem kho raws li qhov pore loj, zoo li,

thiab kev faib tawm, muab qhov yooj yim kom ua tau raws li kev pom tshwj xeeb lossis kev xav tau ntws.

4.High Permeability:

Txawm hais tias lawv lub zog, cov ntawv hlau ntxeem tau tso cai rau siab permeability, kom ntseeg tau

Cov nqi ntws tau zoo rau cov pa roj thiab cov kua dej thaum tswj xyuas kev ua haujlwm pom.

5.Chemical Compatibility:

Cov nplooj ntawv no tau sib xws nrog ntau yam tshuaj, ua rau lawv

zoo tagnrho rau siv nyob rau hauv hnyav ib puag ncig, nrog rau kev ua tshuaj thiab tshuaj industries.

6. Thaum tshav kub kub thiab siab tsis kam:

Cov ntaub ntawv siv hauv cov ntawv hlau ntxeem tau tuaj yeem tiv taus huab cua

qhov kub thiab txias, ua kom muaj kev ruaj ntseg thiab kev cia siab rau hauv kev thov kev thov.

7.Low Maintenance thiab Long Lifespan:

Cov ntawv hlau ntxeem tau zoo heev thiab resistant rau clogging,

txo qhov kev xav tau ntawm kev saib xyuas thiab hloov ntau zaus, yog li ncua lawv lub neej kev pabcuam.

8.Thermal thiab hluav taws xob conductivity:

Ntxiv nrog rau kev pom, cov ntawv hlau ntxeem tau kuj tuaj yeem ua cov thermal

thiab hluav taws xob conductors, broadened lawv daim ntawv thov ntau yam.

Cov yam ntxwv no ua rau cov ntawv hlau ntxeem tau zoo tagnrho rau kev siv hauv kev pom, tswj kev khiav, kev txhawb nqa catalyst,

thiab cov txheej txheem sib cais hauv ntau yam kev lag luam, xws li aerospace, tshuaj ua haujlwm, tshuaj,

thiab ib puag ncig engineering.

Hom Porous Hlau Sheet?

Tiag tiag muaj ob lub ntsiab ntawm cov ntawv hlau ntxeem tau koj tuaj yeem pom

nyob rau hauv lub porous hlau ntawv lag luam:

1. Sintered hlau ntawv:

Cov no yog tsim los ntawm compacting thiab sintering hlau hmoov. Cov pores nyob rau hauv cov nplooj ntawv no feem ntau

interconnected thiab tuaj yeem sib txawv ntawm qhov loj thiab cov duab. Sintered hlau ntawv feem ntau siv rau hauv daim ntawv thov

qhov twg siab zog thiab zoo filtration yuav tsum tau, xws li nyob rau hauv cov ntxaij lim dej, tshav kub exchangers, thiab suab dampeners.

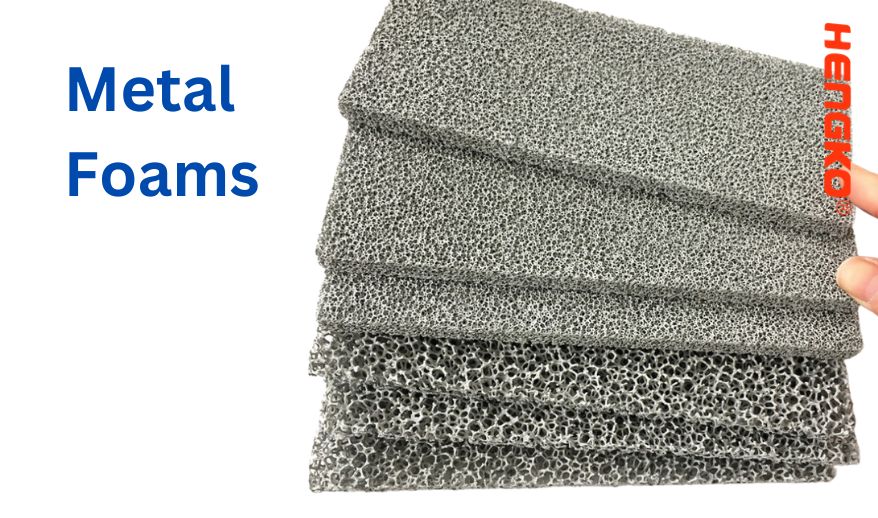

2. Hlau ua npuas ncauj:

Hlau foams yog tsim los ntawm kev qhia cov pa npuas rau hauv cov hlau molten thiab tso cai rau nws kom khov.

Cov pores nyob rau hauv cov nplooj ntawv no feem ntau kaw-cell, txhais tau tias lawv tsis interconnected. Hlau foams yog

feem ntau siv rau hauv cov ntawv thov uas yuav tsum muaj lub teeb yuag thiab siab zog, xws li hauv aerospace thiab

automotive applications.

Nov yog qee qhov lwm yam ntawm cov ntawv hlau ntxeem tau:

1. Woven hlau mesh:

Hom mesh no yog tsim los ntawm kev sib txuas ua ke nyias nyias. Lub pore loj nyob rau hauv woven hlau mesh

tuaj yeem tswj tau los ntawm qhov loj ntawm cov xov hlau thiab cov qauv ntawm cov ntaub. Woven hlau mesh yog feem ntau

siv rau hauv kev sivqhov twg pom thiab cov khoom ntws zoo yog xav tau, xws li hauv cov ntxaij vab tshaus thiab cov ntxaij lim dej.

2. Expanded hlau:

Hom ntawv no yog tsim los ntawm slitting ib daim ntawv ntawm cov hlau nyob rau hauv ib tug tshwj xeeb qauv thiab ces ncab nws.

Cov pores hauv cov hlau nthuav dav feem ntau yog elongated thiab pob zeb diamond-puab. Expanded hlau yog feem ntau

siv rau hauv kev sivqhov twg lub teeb yuag thiab lub zog zoo yuav tsum tau, xws li nyob rau hauv kev ruaj ntseg thiab kev taug kev.

Daim ntawv thov ntawm Sintered Porous Hlau Sheet

Sintered ntxeem tau hlau los xij yog ntau yam kev pom tawm vim lawv cov khoom tshwj xeeb.

Nov yog qee cov ntawv thov uas koj tuaj yeem siv:

* Ib puag ncig kub kub:

* Hnyav Chemical Ib puag ncig:

* Cov Kev Siv Siab Siab:

* Xav tau rau Precise Particle Control:

* Reusability thiab Regenerability:

Tsis tas li ntawm no yog qee qhov kev lag luam uas yuav tau txais txiaj ntsig tshwj xeeb los ntawm kev siv sintered ntxeem tau hlau los xij hauv lawv cov tshuab pom, koj

tuaj yeem tshawb xyuas seb puas yuav zoo rau koj lub cev lossis khoom siv?

* Kev Ua Tshuaj - Rau kev lim dej corrosive thiab gases, thiab catalysts los ntawm cov txheej txheem ntws.

* Fais fab Generation - High-temperature filtration ntawm gases nyob rau hauv fais fab nroj tsuag.

* Kev Lag Luam Pharmaceutical - Ua kom tsis muaj menyuam thiab purity ntawm cov khoom los ntawm kev tshem tawm cov kab mob thiab cov khoom.

* Kev lag luam khoom noj khoom haus & dej haus - Lim kom pom tseeb cov kua, thiab tshem tawm cov khoom tsis xav tau.

* Kev Kho Dej - Pab txhawb rau cov txheej txheem purification los ntawm kev tshem tawm impurities ntawm dej.

Zuag qhia tag nrho, sintered ntxeem tau hlau los xij yog cov cuab yeej muaj txiaj ntsig zoo rau kev ua haujlwm pom cov ntaub ntawv xav tau kev ua haujlwm ntev, kev kub siab ua haujlwm, pom tseeb, thiab rov siv dua.

FAQ

1. Dab tsi yog antxeem tau hlau ntawv, thiab nws ua li cas?

Ib daim ntawv hlau ntxeem tau yog ib hom khoom siv los ntawm nws cov qauv permeable, ua los ntawm

interconnected pores los yog voids thoob plaws nws pawg. Cov ntawv no feem ntau yog tsim los ntawm

txheej txheem hu ua sintering. Sintering cuam tshuam cov hmoov hlau hauv cov pwm thiab tom qab ntawd cua sov

nws hauv qab nws melting point. Qhov kev kho cua sov no ua rau cov khoom hlau sib txuas ua ke yam tsis muaj liquefying,

tsim kom muaj cov qauv tsim nrog precisely tswj porosity.

Cov txheej txheem tso cai rau kev tsim cov nplooj ntawv nrog qhov sib txawv ntawm qhov ntau thiab tsawg, cov duab, thiab kev faib tawm,

haum rau cov ntawv thov tshwj xeeb. Sintered stainless hlau nplooj ntawv, piv txwv li, yog dav siv vim

Lawv cov khoom siv zoo heev, tiv thaiv corrosion, thiab thermal stability.

2. Dab tsi yog cov ntawv thov tseem ceeb ntawm sintered stainless hlau los xij?

Sintered stainless hlau nplooj ntawv yog siv nyob rau hauv ntau yam kev siv vim lawv versatility thiab durability.

Qee qhov kev siv tseem ceeb suav nrog:

* Lim:

Siv nyob rau hauv ob qho tib si roj thiab kua filtration systems, lawv zoo tshem tawm cov teeb meem

vim lawv qhov pore qhov loj.

* Sparging thiab Diffusion:

Qhov zoo tshaj plaws rau cov roj-kua tshuaj, aeration, thiab hauv cov txheej txheem brewing,qhov twg tswj

npuas loj yog qhov tseem ceeb.

* Fluidization:

Ua hauj lwm nyob rau hauv fluidized txaj rau ntau yam tshuaj txheej txheem, pab nyob rau hauv lub txawmkev faib tawm

gases los ntawm cov kua los yog hmoov.

* Kev tiv thaiv Sensor:

Shields rhiab Cheebtsam nyob rau hauv hnyav ib puag ncig, tiv thaiv kev kis kab mob

thaum tso cai rau kev cuam tshuam ib puag ncig tsim nyog.

* Catalyst rov qab thiab txhawb nqa:

Muab lub platform zoo heev rau cov khoom siv catalyst, yooj yim

tshuaj lom neeg cov tshuaj tiv thaiv thaum uas tso cai rau kom yooj yim rov qab ntawm precious catalysts.

3. Koj yuav txiav txim seb qhov pore loj npaum li cas rau ib daim ntawv thov tshwj xeeb?

Kev txiav txim siab qhov pore qhov loj me rau ib daim ntawv thov tshwj xeeb suav nrog kev txiav txim siab

ob peb yam, nrog rau qhov xwm ntawm cov kua los yog gases ua tiav, hom ntawm

cov khoom los yog cov kab mob kom raug tshem tawm, thiab qhov xav tau txaus txaus. Rau kev siv lim,

qhov pore loj yog feem ntau xaiv kom me me dua qhov me me uas xav tau

kom lim tawm. Nyob rau hauv daim ntawv thov uas muaj roj diffusion los yog sparging, qhov pore loj cuam tshuam rau

qhov loj ntawm cov npuas tsim, uas tuaj yeem cuam tshuam qhov ua tau zoo ntawm cov txheej txheem.

Kev sab laj nrog cov ntaub ntawv hlau tsis zoo xws li HENGKO tuaj yeem muab kev pom zoo raws li

Kev paub dav dav thiab kev txawj ntse, ua kom cov kev xaiv ntawm qhov pom qhov pore loj

rau tej daim ntawv thov.

4. Qhov txiaj ntsig zoo li cas sintered stainless hlau ntawv muaj ntau dua lwm cov ntaub ntawv?

Sintered stainless hlau nplooj ntawv muaj ntau yam zoo dua lwm yam ntaub ntawv, ua rau lawv ib tug

nyiam xaiv rau ntau daim ntawv thov kev lag luam:

* Durability:

Lawv lub zog siab thiab tsis kam hnav thiab tsim kua muag ua kom lub neej ua haujlwm ntev nyob rau hauv cov xwm txheej nyuaj.

* Corrosion Resistance:

Stainless hlau lub hauv paus ntawm corrosion kuj yog zoo tagnrho rau siv nyob rau hauv hnyav tshuaj ib puag ncig los yog

qhov twg raug cov ntsiab lus corrosive ntau.

* Kev ruaj ntseg kub siab:

Lawv tuaj yeem tiv taus qhov kub thiab txias yam tsis muaj degrading, ua rau lawv haum rau siv nyob rau hauv tshav kub exchangers,

high-temperature lim, thiab lwm yam kev siv uas yuav tsum tau thermal stability.

* Tshuaj Compatibility:

Stainless hlau yog sib xws nrog ntau yam tshuaj, txo qhov kev pheej hmoo ntawm cov khoom degradation

thiab kis kab mob.

* Cleanability thiab Sterilizability:

Lawv qhov chaw du, tsis ntxeem tau tuaj yeem ntxuav tau yooj yim thiab ua kom tsis muaj menyuam, qhov tseem ceeb hauv kev lag luam

thiab daim ntawv thov zaub mov thiab dej haus.

5. Puas tuaj yeem sintered stainless hlau los xij tuaj yeem hloov kho rau cov ntawv thov tshwj xeeb?

Yog lawm, sintered stainless hlau los xij tuaj yeem ua tau raws li kev thov tshwj xeeb.

Customization tuaj yeem suav nrog kev hloov pauv hauv qhov pore loj, tuab, daim ntawv loj, thiab cov duab, nrog rau kev suav nrog

ntawm cov ntsiab lus alloying tshwj xeeb los txhim kho cov khoom tshwj xeeb xws li conductivity lossis kub tsis kam.

Cov neeg tsim khoom zoo li HENGKO tshwj xeeb hauv kev ua haujlwm nrog cov neeg siv khoom tsim thiab tsim cov hlau ntxeem tau zoo

cov kev daws teeb meem uas ua tau raws li cov kev qhia tshwj xeeb thiab cov qauv kev ua haujlwm uas xav tau rau lawv daim ntawv thov.

Qhov kev hloov kho qib no ua kom ntseeg tau tias cov khoom kawg tuaj yeem ua tau zoo hauv nws qhov chaw npaj,

Txawm hais tias nws muaj cov kev xav tau tshwj xeeb pom, kev ua tshuaj lom neeg tshwj xeeb, lossis lwm daim ntawv thov kev lag luam tshwj xeeb.

Hu rau HENGKO

Npaj los txhawb koj daim ntawv thov kev lag luam nrog bespoke porous hlau daws?

Hu rau peb ntawmka@hengko.comthiab cia peb tig koj cov kev cov nyom rau hauv kev ua tiav.