-

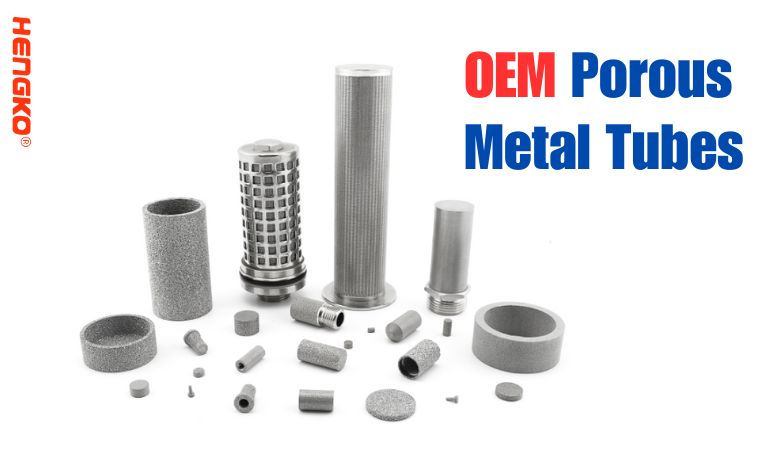

Stainless hlau Sintered ntxeem tau hlau lim Tubes Porosity mus rau 0.2 µm - Hauv F ...

Pore loj: 0.2-100microns Cov Khoom Siv: SS Hlau Porosity: 30% ~ 45% Ua Haujlwm Siab: 3MPa Kev Ua Haujlwm Kub: 600 ℃ Cov ntawv thov rau sintered ntxeem tau hlau ...

Saib nthuav dav -

Hloov Micro-Bubble Porous Sparger Lub Tswv Yim rau Fermentation / Bioreactor Cua Aeration ...

Qhov zoo ntawm HENGKO Porous Metal Micro Spargers Vim yog qhov tsis tshua muaj dej solubility ntawm oxygen nyob rau hauv ntau lub cell kab lis kev cai nruab nrab, optimizing no tseem ceeb nutrient yuav ua tau ...

Saib nthuav dav -

Stainless hlau Tubeless Tire Valve Sturdy Thiab Durable Tyre Valve Luv Qws Rau Tsheb Tru...

Cov Khoom Piav Qhia Lub valve yog ib qho khoom siv lub cev muaj zog uas tso cai rau cov roj nkag mus rau hauv qhov chaw ntawm lub log tsheb lossis lub raj thaum nws qhib, thiab tom qab ntawd ...

Saib nthuav dav -

Lag luam wholesale Hlau Mesh Lim Stainless Hlau 10 Micron Sintered Tube Rau Pharmaceutical M ...

Stainless hlau lim yog zoo tagnrho rau siv nyob rau hauv xav tau engineering specifications uas yuav tsum tau pom nyob rau hauv tsis zoo tej yam kev mob, xws li dav hlau en ...

Saib nthuav dav -

Sintered Porous Hlau Stainless Hlau Lim Tube rau Fiber Optic Collimator HENGKO

Khoom Piav Qhia txog cov khoom siv hlau nplaum tuaj yeem kho tau rau ntau yam kev siv thiab kev qhia tshwj xeeb thiab tuaj yeem txuas rau hlau thiab tsis-meta ...

Saib nthuav dav -

High Accuracy Low Consumption I2C Interface Kub & Humidity txheeb ze Sensor ...

HENGKO kub thiab av noo sensor sojntsuam ua nrog IP66 tiv thaiv qib high-tightness stainless hlau sensor ntxeem tau vaj tse, nws tuaj yeem siv ncaj qha ...

Saib nthuav dav -

Kub thiab txheeb ze humidity sensor sojntsuam nrog stainless hlau extension raj thiab ...

HT-E067 txheeb ze humidity / kub transmitter muab ib txoj kev txhim khu kev qha thiab tus nqi qis rau duct mount xyuas daim ntawv thov. Solid-state sensors r...

Saib nthuav dav -

Sintered Sparger Tube nrog Porous Hlau Stainless Hlau Tank thiab In-line Sparkers Siv ...

Qhia txog qhov tshwj xeeb HENGKO sintered spargers, qhov kawg kev daws teeb meem los qhia cov pa roj rau hauv cov kua. Cov khoom tshiab no siv ntau txhiab tus ...

Saib nthuav dav -

Kev ua haujlwm siab ntxeem tau sintered hlau stainless hlau isostatic lim raj txhawb nqa ...

Stainless hlau sintered raj yog ua los ntawm stainless hlau hmoov, ua tiav los ntawm sintering tshuab. Cov khoom no tuaj yeem ntxuav cov kab mob tsis huv thiab ua rau ...

Saib nthuav dav -

Hydrogen nplua nuj dej tshuab - sintered SS 316L stainless hlau 0.5 2 micron cua o ...

Hydrogen dej yog huv si, muaj zog, thiab nrog hydrogen. Nws pab ntxuav cov ntshav thiab ua kom cov ntshav txav mus. Nws tuaj yeem tiv thaiv ntau yam kab mob thiab txhim kho peo ...

Saib nthuav dav -

Txhim kho ncaj nraim Porous hlau In-Line Sparger Tube tsim cov npuas me

HENGKO sintered spargers qhia cov pa roj rau hauv cov kua los ntawm ntau txhiab lub qhov hws me me, tsim cov npuas me me thiab ntau dua li cov yeeb nkab drilled ...

Saib nthuav dav -

316L stainless hlau ntxeem tau hlau ncaj lim raj zoo li sparging sib dhos

Sintered cua pob zeb diffusers feem ntau yog siv rau kev txhaj tshuaj porous. Lawv muaj qhov sib txawv pore qhov ntau thiab tsawg (0.5um rau 100um) cia cov npuas me me ntws los ntawm t ...

Saib nthuav dav -

316L stainless hlau ntxeem tau sparger raj sintered ntsis rau fermentation nkoj accessories

Txuas mus rau qhov kawg ntawm lub raj sparger, qhov no 316L stainless hlau sintered ntsis yog muaj nyob rau hauv ntau qhov ntau thiab tsawg pore. 5 10 15 50 100 pore frit yog qhov ...

Saib nthuav dav -

Cylindrical 25 50 micron stainless hlau microns ntxeem tau hmoov sintered lim raj rau ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Porous hlau lim raj rau thermal tswj refining thiab tshwj xeeb tshuaj | HENGKO

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Cov chaw tsim khoom lag luam customized sintered ntxeem tau hlau lim raj siv rau kev kho mob ...

HENGKO sintered cov ntxaij lim dej feem ntau yog siv rau kev ua kom huv thiab pom cov kua thiab roj, kev sib cais thiab rov qab ntawm cov khoom siv, cov khoom cua txias ...

Saib nthuav dav -

0.2um rau 90 micron 5 - 100mm siab hmoov los yog hlau mesh ntxeem tau sintered hlau sta ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Sintered hlau hmoov ntxeem tau 316l SS stainless hlau lim raj, 2 μm 5 7 10 15 20 30 ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

2 10 20 25 microns ntxeem tau SS 304 / 316L hlau sintered stainless hlau lim raj rau li ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Sintered hlau 316 stainless hlau lim kho mob micro lim raj rau kua thiab roj ...

Khoom Piav Qhia Cov khoom siv lim dej tau siv dav hauv metallurgical, tshuaj, tshuaj, aerospace, thiab aviation teb. Porous Hlau Media ...

Saib nthuav dav

Vim li cas thiaj siv Porous Hlau Tube?

Muaj ob peb lub ntsiab yog vim li cassintered hlau rajyog siv nyob rau hauv ntau yam kev siv:

Lim:

* Lawv lub luag haujlwm tseem ceeb yog kev pom. Cov tswj qhov pore qhov me me tso cai rau lawv tshem tawm impurities,

particles, thiab kab mob los ntawm cov kua thiab gases. Qhov no tuaj yeem yog qhov tseem ceeb hauv kev lag luam xws li kws tshuaj,

chemical processing, thiab zaub mov thiab dej haus, qhov purity yog qhov tseem ceeb.

* Qhov ntau thiab tsawg ntawm pore tuaj yeem nyob ntawm submicron mus rau ntau millimeters, ua rau lawv lim tawm ntau qhov ntau thiab tsawg.

Tswj Flow:

* Cov qauv ntxeem tau tso cai rau kev tswj xyuas cov kua thiab cov pa.

Qhov no tuaj yeem siv rau aeration, gas tis, fluidization, thiab lwm yam kev siv uas yuav tsum muaj kev tswj xyuas meej ntawm kev ntws.

* Lub cev pore faib ua kom zoo sib xws thoob plaws hauv lub raj, tiv thaiv channeling thiab tsis sib npaug ntawm qhov siab.

Durability thiab Strength:

* Ua los ntawm cov hlau zoo li stainless hlau, npib tsib xee, los yog tooj liab, cov hlau ntxeem tau zoo heev thiab tuaj yeem ua haujlwm hnyav.

tej yam kev mob, xws li kub siab, siab, thiab corrosive ib puag ncig.

* Qhov no ua rau lawv haum rau kev siv mus sij hawm ntev hauv kev thov kev lag luam.

Lwm cov txiaj ntsig:

* Cov raj hlau ntxeem tau kuj hnav, yooj yim ntxuav, thiab rov ua dua tshiab. Lawv tuaj yeem yooj yim machined thiab zoo li tus rau hauv ntau hom,

ntxiv expanding lawv versatility.

Nov yog qee qhov piv txwv tshwj xeeb ntawm cov ntawv thov uas siv cov raj hlau ntxeem tau:

* Cua diffusers:nyob rau hauv cov dej khib nyiab kho cov nroj tsuag kom paub cov pa oxygen rau hauv dej rau cov kab mob loj hlob.

* Roj lim:nyob rau hauv tsheb thiab lwm yam tsheb kom tshem tawm impurities ntawm roj.

* Medical implants:rau pob txha ingrowth thiab xa tshuaj.

* Kev txhawb nqa Catalyst:nyob rau hauv tshuaj reactors tuav thiab faib catalysts.

* Silencers:nyob rau hauv lub tshuab tso pa kom txo cov suab nrov.

Thaum kawg, cov laj thawj tshwj xeeb yog vim li cas ib tus neeg yuav xaiv lub raj hlau ntxeem tau nyob ntawm daim ntawv thov tshwj xeeb

thiab nws cov cai. Txawm li cas los xij, lawv qhov tshwj xeeb ua ke ntawm kev pom, tswj kev khiav, kav ntev, thiab lwm yam txiaj ntsig

ua rau lawv yog cov cuab yeej muaj txiaj ntsig rau ntau yam kev lag luam.

Main Function

Covsintered hlau rajyuav luag tib lub luag haujlwm nrog lwm tussintered hlau lim or sintered hlau sparger.

Lub luag haujlwm tseem ceeb ntawm cov raj hlau ntxeem tau yog los muab kev pom zoo thiab txhim khu kev qha, sib cais, thiab tswj

ntawm cov kua thiab gas ntws.

Cov porous hlau raj no yog tsim los ntawm zoo 316L SS hlau hais uas yog fused ua ke los ntawm ib tug sintering.

txheej txheem, tsim ib tug qauv nrog interconnected pores. Cov yam ntxwv tshwj xeeb ntawm cov hlau ntxeem tau

pab kom lawv ua haujlwm ntau yam tseem ceeb:

1. Lim:

Lub hom phiaj tseem ceeb ntawm cov raj hlau ntxeem tau yog los ua cov lim dej, tshem tawm cov impurities, cov khoom, thiab cov kab mob ntawm cov kua thiab cov pa.

Kev tswj xyuas meej ntawm qhov pore loj tso cai rau lawv kom ua tiav qhov pom zoo mus rau qib submicron, ua kom cov purity ntawm qhov nruab nrab ua tiav.

2. Gas thiab Liquid Dispersion:

Porous hlau rajyog siv los disperse gases los yog kua tusyees thiab uniformly. Los ntawm kev tswj cov pore loj thiab kev faib tawm,

lawv tuaj yeem tsim cov qauv ntws zoo sib xws, tiv thaiv channeling thiab txhim kho kev ua haujlwm tawg.

3. Fluidization:

Nyob rau hauv cov ntaub ntawv fluidized txaj, cov hlab no yog ua hauj lwm los fluidize cov khoom, tsim kom muaj ib tug suspended kua zoo li lub xeev.

Kev faib tawm tsis sib xws ntawm qhov pores pab ua kom tau txais txiaj ntsig zoo thiab tswj cov kua dej.

4. Qhov cua thiab qhov sib npaug sib npaug:

Cov raj hlau ntxeem tau siv rau kev tso pa tawm, sib npaug ntawm qhov sib npaug, lossis txo lub tshuab nqus tsev hauv ntau lub tshuab

thiab cov khoom siv. Lawv tso cai rau kev nkag ntawm huab cua lossis roj thaum tiv thaiv kev nkag mus ntawm cov kab mob.

5. Txo suab nrov:

Hauv qee qhov kev siv, cov raj hlau ntxeem tau siv los ua silencers lossis mufflers los txo cov suab nrov uas tsim los ntawm kev ntws ntawm cov pa roj lossis kua dej.

6. Diffusion:

Cov raj hlau ntxeem tau yooj yim rau cov txheej txheem roj los yog kua diffusion los ntawm kev tso cai rau cov molecules kom dhau los ntawm lawv cov pores sib cuam tshuam.

Cov cuab yeej no pom cov ntawv thov hauv ntau qhov chaw, xws li catalysis thiab kev ua haujlwm loj.

7. Kev them nyiaj yug thiab kev faib tawm:

Hauv qee qhov kev lag luam, cov hlau ntxeem tau ua raws li cov qauv kev txhawb nqa rau cov catalysts lossis lwm yam khoom, muab kev ruaj khov.

lub moj khaum thiab pab nyob rau hauv uniform kev faib.

Vim lawv cov porosity siab, durability, tshuaj tiv thaiv, thiab tswj tau qhov pore lug, porous hlau hlab pom nws kim heev.

siv nyob rau hauv kev lag luam xws li tshuaj, petrochemicals, dej kho mob, tsheb, aerospace, thiab ntau yam ntxiv,

qhov twg muaj txiaj ntsig pom thiab tswj cov txheej txheem ntws yog qhov tseem ceeb rau kev ua haujlwm zoo thiab kev nyab xeeb.

Txoj Cai Ua Haujlwm ntawm Sintered Porous Hlau Tubes

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm sintered ntxeem tau hlau raj yog ua raws li cov khoom tshwj xeeb ntawm sintered hlau qauv,

uas tso cai rau kom muaj txiaj ntsig zoo thiab tswj cov dej ntws thiab cov pa roj. Nov yog ib qho piv txwv ntawm txoj cai ua haujlwm:

1. Sintering txheej txheem:

Porous hlau raj yog tsim los ntawm cov txheej txheem hu ua sintering. Nws suav nrog compacting hlau hais, feem ntau

stainless hlau los yog lwm yam hlau alloys, mus rau hauv ib tug tshwj xeeb zoo, xws li ib tug raj. Cov hlau hais yog rhuab mus rau qhov kub thiab txias

tsuas yog hauv qab lawv cov ntsiab lus melting, ua rau lawv fuse ua ke, tsim cov khoom sib txuas thiab sib txuas ntawm qhov pores.

2. Pore Structure:

Lub sintered hlau raj muaj ib tug txhais pore qauv vim yog kev npaj ntawm hlau hais thaum lub sij hawm sintering txheej txheem.

Qhov luaj li cas, cov duab, thiab kev faib tawm ntawm cov pores no tuaj yeem tswj tau meej thaum lub sijhawm tsim khoom kom ua tau raws li qhov xav tau tshwj xeeb pom.

3. Lim:

Lub luag haujlwm tseem ceeb ntawm sintered ntxeem tau hlau raj yog pom. Thaum cov kua los yog roj nkag mus rau hauv lub raj, cov pa paug,

particles, thiab impurities yog ntes nyob rau hauv lub pores. Qhov pore loj yog tsim los tso cai rau cov kua dej los yog cov pa uas xav tau dhau mus

thaum thaiv cov khoom tsis xav tau.

4. Lim Efficiency:

Qhov pom kev ua haujlwm ntawm sintered ntxeem tau hlau raj nyob ntawm qhov pore loj thiab tag nrho thaj chaw muaj rau pom.

Cov pore me me tuaj yeem ntes cov khoom me me, muab kev pom zoo dua.

5. Flow Control:

Cov qauv sib txuas ntawm qhov pore ntawm sintered hlau raj ua rau muaj kev tswj xyuas meej ntawm cov kua dej lossis roj ntws. Qhov loj thiab

Kev faib tawm ntawm qhov pores cuam tshuam tus nqi ntws thiab siab poob thoob plaws lub raj. Cov cuab yeej no yog qhov tseem ceeb hauv kev siv

qhov twg yuav tsum tau muaj kev faib tawm los yog tswj cov kua dej.

6. Durability thiab Resistance:

Sintered hlau raj yog ruaj thiab resistant rau txhua yam kev nyuaj siab, tshuaj, thiab kub kub. Qhov sintering

txheej txheem ua kom ntseeg tau tias cov hlau hais tau ruaj khov, muab cov qauv kev ntseeg siab txawm tias nyob rau hauv kev ua haujlwm nyuaj.

7. Reusability thiab Cleanability:

Sintered ntxeem tau hlau raj tuaj yeem yooj yim ntxuav thiab rov siv dua. Lawv tuaj yeem tiv taus ntau yam kev tu,

xws li backwashing, ultrasonic tu, los yog tshuaj ntxuav, tsis muaj kev cuam tshuam lawv pom efficiency.

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm sintered ntxeem tau hlau raj ua rau lawv muaj ntau yam thiab haum rau ntau yam.

kev siv hauv kev lag luam xws li petrochemicals, kws tshuaj, kev kho dej, aerospace, thiab lwm yam. Lawv yog

xaiv rau lawv cov kev pom zoo, ua haujlwm ntev, thiab muaj peev xwm tiv taus qhov hnyav hnyav, muab kev ua haujlwm ruaj khov

hauv cov txheej txheem tseem ceeb thiab cov tshuab.

Dab tsi koj yuav tsum saib xyuas OEM Porous Hlau Tubes?

Thaum txiav txim siab OEM tshwj xeeb porous hlau raj rau koj qhov kev pom lossis cov haujlwm, muaj ntau ntau

Cov yam tseem ceeb uas yuav tsum tau coj mus rau hauv tus account kom ntseeg tau tias kev ua tau zoo thiab kev ua tau zoo.

Nov yog qee qhov kev txiav txim siab tseem ceeb:

1. Cov kev xav tau lim:

Qhia meej meej txog qhov yuav tsum tau ua kom pom tseeb rau koj daim ntawv thov. Txiav txim siab qhov xav pom kev ua haujlwm,

pore loj, thiab txaus tus nqi xav tau kom ua tiav qhov xav tau.

2. Cov yam ntxwv ua kua lossis roj:

Nkag siab txog cov khoom ntawm cov kua lossis roj los lim, suav nrog qhov kub thiab txias, siab, viscosity, thiab tshuaj lom neeg

kev sib haum xeeb. Xyuas kom meej tias cov khoom siv hlau uas tau xaiv tuaj yeem tiv taus cov kev ua haujlwm uas xav tau.

3. Pore Loj thiab cov qauv:

Ua haujlwm nrog OEM chaw tsim khoom los kho qhov pore loj thiab cov qauv ntawm cov hlau ntxeem tau kom haum koj

daim ntawv thov xav tau. Xav txog qhov loj me me ntawm cov kab mob uas yuav tsum tau muab tshem tawm thiab cov yam ntxwv ntws xav tau.

4. Kev xaiv cov khoom siv:

Xaiv cov khoom siv hlau tsim nyog raws li nws cov tshuaj tiv thaiv, cov khoom siv kho tshuab, thiab kev sib raug zoo nrog

qhov nruab nrab raug lim. Cov khoom siv feem ntau suav nrog stainless hlau, tooj liab, npib tsib xee, thiab titanium.

5. Tsim thiab Geometry:

Koom tes nrog OEM chaw tsim khoom los tsim lub raj cov duab thiab qhov ntev kom haum rau koj lub cev lossis qhov project.

Xav txog yam xws li qhov ntev, txoj kab uas hla, thiab qhov kawg kev sib txuas rau kev sib koom ua ke yooj yim.

6. Lim Efficiency thiab Siab poob:

Sib npaug qhov pom kev ua haujlwm nrog lub siab poob thoob plaws cov hlau ntxeem tau. Kev lim dej ntau dua tuaj yeem ua tau

ua rau nce siab poob, uas tuaj yeem cuam tshuam rau kev ua haujlwm ntawm lub cev.

7. Kev huv thiab tu:

Sib tham txog kev huv thiab kev saib xyuas ntawm cov raj hlau ntxeem tau. Xyuas kom lawv tuaj yeem ntxuav tau yooj yim

thiab rov siv dua los ua kom zoo dua lub neej thiab txo qis sijhawm.

8. Customization thiab kev txawj ntse:

Ua haujlwm nrog cov chaw tsim khoom OEM uas muaj kev paub dhau los nrog cov ntaub ntawv pov thawj hauv kev tsim cov hlau ntxeem tau tshwj xeeb.

Lawv yuav tsum muaj kev txawj ntse los kho cov raj raws li koj qhov kev xav tau tshwj xeeb.

Los ntawm ua tib zoo xav txog cov xwm txheej no thiab koom tes nrog OEM cov chaw tsim khoom, koj tuaj yeem xyuas kom meej tias cov

OEM tshwj xeeb ntxeem tau hlau raj yog tsim thiab tailored kom tau raws li koj filtration system los yog qhov project qhov tshwj xeeb xav tau kev pab,

Thaum kawg ua rau kev txhim kho efficiency, kev cia siab, thiab kev ua haujlwm.

FAQ

1. Dab tsi yog qhov tseem ceeb ntawm cov porous sintered hlau raj?

Porous sintered hlau raj muaj ob peb yam tseem ceeb uas ua rau lawv tshwj xeeb thiab muaj txiaj ntsig zoo rau

ntau yam kev siv. Cov yam ntxwv no muaj xws li:

* High Filtration Efficiency:

Kev tswj xyuas meej ntawm qhov pore loj tso cai rau kev pom zoo mus rau qib submicron,

xyuas kom tshem tawm cov kab mob thiab impurities ntawm cov kua thiab gases.

* Durability thiab muaj zog:

Sintering txheej txheem bonds hlau hais, muab txhua yam muaj zog thiab kuj

rau deformation, txawm nyob rau hauv hnyav tej yam kev mob.

* Dav Kub thiab Siab Ntau Yam:

Cov hlab ntsha tuaj yeem ua haujlwm nyob rau hauv ib puag ncig huab cua, tswj kev ua haujlwm zoo thiab pom

efficiency thoob plaws ntau yam kub thiab siab.

* Tshuaj Compatibility:

Lawv yog cov tshuaj inert thiab resistant rau corrosion, ua rau lawv haum rau lim aggressive

tshuaj thiab corrosive media.

* Cleanability thiab Reusability:

Porous sintered hlau raj tuaj yeem ntxuav tau yooj yim thiab rov qab siv ntau zaus, txo kev txij nkawm

tus nqi thiab ncua lub lim lub neej.

2. Cov porous sintered hlau raj ua haujlwm li cov lim dej li cas?

Kev ua haujlwm ntawm cov porous sintered hlau raj raws li cov ntxaij lim dej yog raws li lawv cov qauv pore sib cuam tshuam.

Thaum cov kua los yog roj ntws los ntawm lub raj, cov kab mob thiab cov khoom raug ntes nyob rau hauv lub qhov hws.

thaum tso cai rau qhov nruab nrab xav tau dhau mus. Qhov loj me, kev faib tawm, thiab kev npaj ntawm pores

txiav txim siab qhov kev ua kom pom tseeb thiab hom khoom uas tuaj yeem raug tshem tawm. Cov hlau sintered siab

porosity thiab nplua pores pab kom zoo pom, ua cov hlab no zoo tagnrho rau cov ntawv thov tseem ceeb qhov twg

yuav tsum tau ua kom pom tseeb thiab txhim khu kev qha.

3. Dab tsi yog qhov kev txiav txim siab rau kev txhim kho cov porous sintered hlau raj hauv ib qho system?

Kev txhim kho kom zoo yog qhov tseem ceeb los xyuas kom meej qhov kev ua tau zoo ntawm cov porous sintered hlau raj. Qee qhov kev txiav txim siab suav nrog:

* Zoo sealing:

Ua kom muaj kev ruaj ntseg thiab tsis muaj kev sib txuas ntawm ob qho kawg ntawm lub raj kom tiv thaiv kev hla thiab tswj xyuas qhov ua tau zoo.

* Kev taw qhia:

Tso lub raj kom raug kom ntseeg tau tias cov kev taw qhia ntws sib haum nrog nws txoj haujlwm tsim, txawm tias nws yog rau kev pom, qhov cua, lossis cov kua dej.

* Txhawb nqa thiab tiv thaiv:

Muab kev txhawb nqa txaus thiab kev tiv thaiv kom tsis txhob muaj kev puas tsuaj rau cov hlab thaum lub sijhawm teeb tsa thiab ua haujlwm.

4. Cov ntawv thov twg tuaj yeem siv cov sintered hlau porous?

Porous sintered hlau raj pom cov ntawv thov thoob plaws ntau yam kev lag luam, suav nrog:

Petrochemicals thiab Refining:Rau kev txhawb nqa catalyst, pom cov txheej txheem ua kua, thiab kev siv roj diffusion.

Pharmaceuticals:Nyob rau hauv sterile venting, gas filtration, thiab tshuaj xa cov tshuab.

Kev kho dej:Rau kev kho dej khib nyiab, aeration, thiab pom cov dej haus.

Aerospace:Nyob rau hauv roj thiab hydraulic systems rau filtration thiab venting.

Automotive:Hauv kev tswj emission, roj pom, thiab lubrication tshuab.

Khoom noj khoom haus thiab dej haus:Rau haus carbonation, aeration, thiab steam filtration.

5. Yuav ua li cas porous sintered hlau raj ua rau lub system efficiency thiab kev ua tau zoo?

Porous sintered hlau raj txhim khu kev ua haujlwm thiab kev ua tau zoo los ntawm:

* Ua kom pom kev ua haujlwm siab, ua rau kom huv thiab huv dua cov kua lossis roj.

* Muab kev faib tawm tsis sib xws, tiv thaiv channeling lossis tsis sib xws ntawm kev faib tawm.

* Nrog rau cov xwm txheej hnyav, txo qis sijhawm thiab cov nqi kho.

* Ua kom cov roj diffusion thiab fluidization txheej txheem, optimizing tshuaj tiv thaiv thiab kev ua haujlwm loj.

6. Cov kev tswj xyuas zoo li cas yog ua haujlwm thaum lub sij hawm tsim cov porous sintered hlau raj?

HENGKO raws li Sab saum toj Sintered Hlau Lim cov tuam txhab siv cov kev tswj xyuas nruj zoo thoob plaws hauv kev tsim khoom. Qhov no suav nrog:

* Cov Khoom Siv Zoo: Siv cov khoom siv qib siab hlau kom ntseeg tau tias muaj zog thiab tshuaj lom neeg.

* Kev tswj qhov pore: Precise tswj ntawm sintering tsis kom ua tiav qhov xav tau qhov pore loj thiab kev faib tawm.

* Dimensional Accuracy: Ua kom nruj nruj kom ua tau raws li cov neeg siv khoom tshwj xeeb.

* Kev Ntsuam Xyuas Kev Ua Haujlwm: Ua qhov kev ntsuam xyuas pom kev ua haujlwm, kev ntsuas kev poob siab, thiab kev ntsuas lub zog ntawm lub zog.

Tsis txhob yig tiv tauj peb rau kev sab laj thiabcia peb pab koj optimize koj qhov system pom los yog qhov project.

Email rau peb ntawmka@hengko.comtam sim no thiab ua thawj kauj ruammus rau enhanced efficiency thiab kev ua tau zoo nrog

HENGKO's QualitySintered hlau raj.