-

High Pressure Snow Foam Generator Mesh Lim

High-pressure snow ua npuas ncauj lancer compressed knitted hlau mesh lim Kev kub siab ua npuas ncauj txiag thiab ua npuas ncauj generator nozzles los ua ke hauv Snow Foam Lance. Ua npuas ncauj...

Saib nthuav dav -

Cov yeeb nkab lim Stainless hlau 304 316 Mesh Screen Lim

Cigarette mesh filter disc tseem hu ua luam yeeb lim mesh disc, bong burner mesh, Arabic hookah lim, los yog faucet dej impurity lim. Nws yog feem ntau koj ...

Saib nthuav dav -

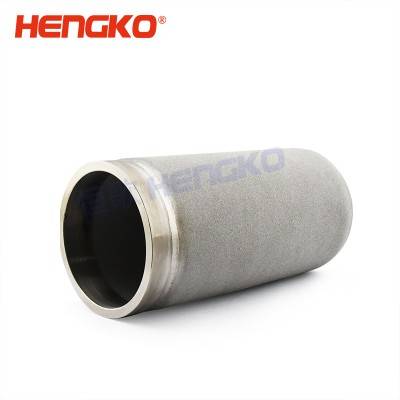

Lag luam wholesale Hlau Mesh Lim Stainless Hlau 10 Micron Sintered Tube Rau Pharmaceutical M ...

Stainless hlau lim yog zoo tagnrho rau siv nyob rau hauv xav tau engineering specifications uas yuav tsum tau pom nyob rau hauv tsis zoo tej yam kev mob, xws li dav hlau en ...

Saib nthuav dav -

20 Micron 316 Stainless Hlau Hlau Mesh Lim Cartridge Inner Core 32mm Ntev M4 Xov

Hlau mesh lim yog hlau mesh uas yog stretched los ntawm kev siv hlau threads, nrog zoo qhib ntawm txawv hlau threads. Thaum cov dej tsis huv yog lub twj tso kua...

Saib nthuav dav -

Rov qab Osmosis Stainless Hlau Lim Dej Lim Purifier Pom Qhov System SS 316 M ...

Rov qab Osmosis Stainless Hlau Lim Dej Lim Purifier Lim System SS 316 Mesh Cartridge Lim Cov Khoom Muag Txhua tus tab tom nrhiav n...

Saib nthuav dav -

RHTX Series mesh-tiv thaiv huab cua-pov thawj humidity sensor sojntsuam vaj tse

HENGKO stainless hlau sensor plhaub yog tsim los ntawm sintering 316L hmoov khoom ntawm qhov kub thiab txias. Lawv tau siv dav hauv kev tiv thaiv ib puag ncig, ...

Saib nthuav dav -

HK83MCN RHT31 35 30 flameproof kub humidity sensor ntxeem tau sintered stainless s ...

HENGKO stainless hlau sensor plhaub yog tsim los ntawm sintering 316L hmoov khoom nyob rau hauv qhov kub thiab txias. Lawv tau siv dav hauv kev tiv thaiv ib puag ncig, p ...

Saib nthuav dav -

± 2% ultra-low-power mesh-tiv thaiv huab cua-pov thawj huab cua muaj txheeb ze av noo thiab h ...

RHT-H hnyav RH&T av noo sensor sojntsuam, tsim los ntawm HENGKO, yog rugged, raug kub thiab av noo soj ntsuam uas zoo tagnrho rau lub sij hawm ntev, u ...

Saib nthuav dav -

HK20G1/8U RHT30 i2c Mesh-tiv thaiv huab cua-pov thawj wireless kub thiab av noo sens ...

HENGKO wifi digital kub thiab av noo module txais siab precision RHT series sensor nruab nrog sintered hlau lim plhaub rau huab cua loj permeab ...

Saib nthuav dav -

4-20mA Infrared CH4 CO2 roj sensor ( carbon dioxide sensor ) ntes aluminium alloy ho ...

Stainless hlau vaj tse nrog tamperproof tiv thaiv. Rau kev siv nrog cais cov ntawv pov thawj, kev lag luam-tus qauv hlws ris lub thawv lossis OEM gas detector enclosures. ...

Saib nthuav dav -

Sintered stainless hlau / hlau mesh tawg-pov thawj lim vaj tsev rau carbon monoxide l ...

HENGKO tawg-pov thawj sensor vaj tsev yog ua los ntawm 316L stainless hlau thiab txhuas rau kev tiv thaiv corrosion siab tshaj plaws. Lub sinter-bonded nplaim ntes muab ...

Saib nthuav dav -

Stainless Hlau Hlau Mesh Lim zaum kawg lim rau kev lag luam luam ntawv

HENGKO manufactures hlau mesh lim ntsiab nyob rau hauv ib tug ntau yam ntawm cov ntaub ntawv, qhov ntau thiab tsawg, thiab fittings yog li lawv tau yooj yim teev nrog cov yam ntxwv ntawm ...

Saib nthuav dav -

Sintered Hlau Stainless Hlau ntxeem tau mesh lim rau nyob rau hauv High Pressure Environments

Hengko cov khoom noj khoom haus-qib textile lim yog tsim los ntawm cov khob, threaded khob, discs, thiab cov khoom txuas ntxiv. Cov lim dej no yog qhov tseem ceeb ...

Saib nthuav dav -

Gas Diffusion Layers Sheet rau MEAs, stainless hlau ntxeem tau hlau sintered / hlau mesh ...

HENGKO stainless hlau lim daim hlau yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau ...

Saib nthuav dav -

Precious Hlau Catalyst Lim - Stainless hlau ntau txheej mesh lim tswm ciab

HENGKO tsim cov khoom lim hauv ntau yam khoom, qhov ntau thiab tsawg, thiab fittings kom lawv tau yooj yim teev nrog cov yam ntxwv thiab configura ...

Saib nthuav dav -

Zoo siab y lim lim, sintered lim mesh rau roj pom

y strainer lim mesh yog siv hauv cov kav dej kom tiv thaiv cov khib nyiab los ntawm cov kav dej. Cov kua dej dhau los ntawm sintered lim, uas lim tawm txawv teb chaws ma ...

Saib nthuav dav -

0.2um rau 90 micron 5 - 100mm siab hmoov los yog hlau mesh ntxeem tau sintered hlau sta ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

5 10 25 micorns ntxeem tau 316L stainless hlau hmoov / hlau mesh sintered hlau refillable ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Multi-layer sintered stainless hlau mesh phaj fluidized txaj khoom Distributor bot ...

Stainless hlau mesh phaj rau kua txaj Tswj kev faib roj, hmoov khoom kis tau tus mob, thiab ua haujlwm fluidization tau dav siv hauv indu ...

Saib nthuav dav -

me me sintered stainless hlau mesh disc lim rau siv rau inkjet Printers

Sinter hlau mesh cov ntxaij lim dej feem ntau yog siv rau kev ua kom huv thiab pom cov kua thiab roj, kev sib cais thiab rov qab cov khoom siv, transpiration coolin ...

Saib nthuav dav

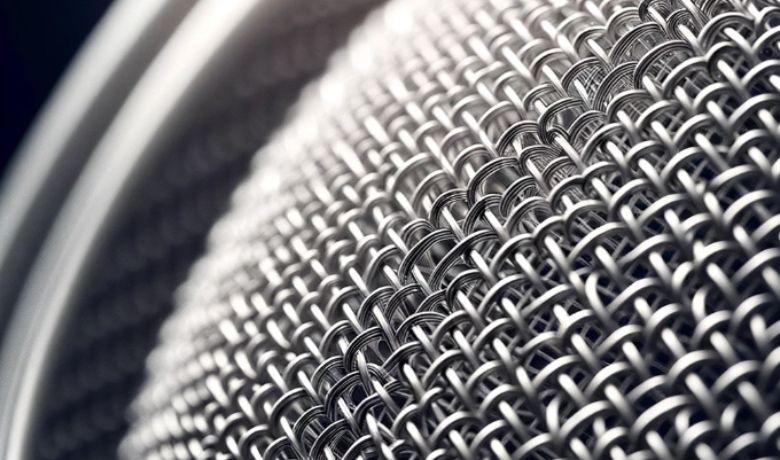

Dab tsi yog sintered mesh?

Yooj yim hais, Ib qho sintered mesh yog cov hlau lim ua los ntawm fusing ua ke ntau txheej ntawm woven hlau mesh

los ntawm cov txheej txheem hu ua sintering.

Thaum lub sij hawm sintering, mesh txheej yog rhuab thiab nias ua ke, tsim ib tug muaj zog thiab ruaj khov qauv.

Cov khoom tsim tau muaj qhov sib txawv ntawm qhov pore thiab muaj peev xwm pom zoo, ua rau nws haum rau

ntau yam kev siv hauv kev lag luam uas yuav tsum tau ua kom pom tseeb thiab txhim khu kev qha.

Vim li cas thiaj siv Sintered Stainless Hlau Mesh?

Sintered stainless hlau mesh muaj ntau yam zoo uas ua rau nws xaiv zoo tshaj plaws rau ntau yam kev lag luam:

1. Durability:

Sintered stainless hlau yog heev resistant rau corrosion, ua rau nws haum rau hnyav ib puag ncig thiab ntev siv.

2.High Filtration Efficiency:

Cov txheej txheem sintering tsim cov qauv pore uas tso cai rau kev pom zoo ntawm cov khoom, muab kev pom zoo rau ob qho tib si kua thiab roj.

3.Customizable Pore Loj:

Cov neeg tsim khoom tuaj yeem tsim cov sintered meshes nrog ntau qhov pore qhov ntau thiab tsawg kom tau raws li cov kev cai pom zoo, ua rau lawv muaj ntau yam rau kev siv sib txawv.

4.Mechanical Strength:

Sintered stainless hlau mesh yog qhov muaj zog thiab tuaj yeem tiv taus qhov kub siab, kub, thiab ntws tus nqi yam tsis muaj deforming.

5. Yooj yim ntxuav:

Cov meshes no tuaj yeem ntxuav tau siv ntau txoj hauv kev (xws li backflushing, ultrasonic tu), uas ua rau lawv lub neej ntev thiab tswj kev ua haujlwm.

6.Chemical Resistance:

Lawv tuaj yeem tswj tau ntau yam tshuaj, ua rau lawv tsim nyog rau kev siv tshuaj, khoom noj thiab dej haus, thiab kev lag luam tshuaj.

7.Tsis muaj tshuaj lom thiab nyab xeeb:

Ua los ntawm cov hlau tsis muaj steel, lawv yog cov tsis muaj tshuaj lom thiab tsis tso cov tshuaj phem rau hauv cov ntaub ntawv ua tiav.

8.Cov nqi-zoo:

Thaum thawj zaug peev yuav siab dua, qhov ua haujlwm ntev thiab rov siv tau ntawm sintered stainless hlau mesh tuaj yeem ua rau kev txuag nyiaj mus sij hawm ntev.

9.Cov ntawv thov hauv ntau hom kev lag luam:

Lawv tau siv ntau yam, suav nrog kev kho dej, roj thiab roj, tshuaj, thiab kev ua zaub mov, vim lawv muaj ntau yam thiab kev ntseeg tau.

Cov yam ntxwv no ua rau sintered stainless hlau mesh yog ib qho kev xaiv zoo tshaj plaws rau kev lag luam uas xav tau kev ua haujlwm siab pom kev daws teeb meem.

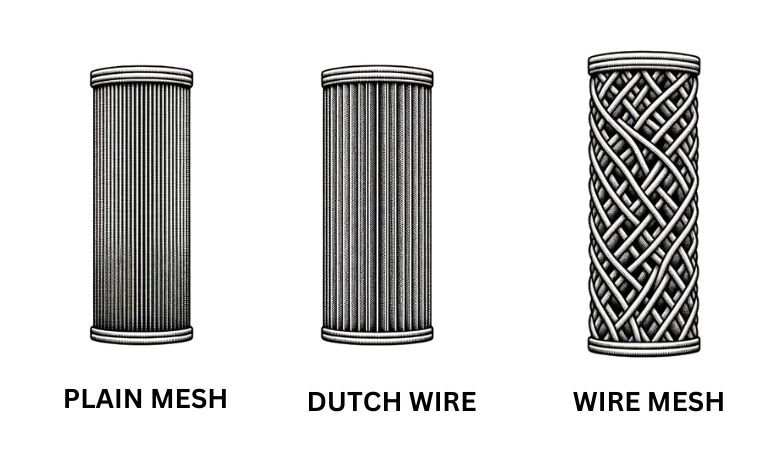

Hom Sintered Mesh Lim?

Sintered mesh lim tuaj nyob rau hauv ntau hom raws li lawv cov qauv, txheej, thiab kev siv tshwj xeeb. Qee yam ntawm cov hom muaj xws li:

1. Ib Txheej Sintered Mesh:

Ua los ntawm ib txheej ntawm woven hlau mesh uas tau sintered los txhim kho nws lub zog thiab rigidity.

2. Multi-layer Sintered Mesh:

Qhov no suav nrog stacking ob peb txheej ntawm woven hlau mesh thiab ces sintering lawv ua ke. Cov txheej txheem ntau txheej boosts mechanical zog thiab pom tseeb.

3. Sintered Square Woven Mesh:

Ua los ntawm square woven hlau mesh khaubncaws sab nraud povtseg sintered ua ke, hom no muaj xws li pore ntau thiab tsawg thiab yog feem ntau siv nyob rau hauv ntau yam pom daim ntaub ntawv.

4. Dutch Woven Sintered Mesh:

Qhov no ua ke ntau txheej ntawm Dutch woven hlau meshes, uas yog ces sintered. Qhov tshwm sim yog lub lim dej nrog cov peev xwm zoo filtration.

5. Perforated Hlau Sintered Mesh:

Hom no muab ib los yog ntau txheej ntawm woven hlau mesh nrog ib txheej ntawm perforated hlau. Cov hlau perforated muab lub zog ntxiv, thaum cov hlau mesh txheej muab pom.

6. Sintered Fiber Felt Mesh:

Es tsis txhob woven hlau, lim no siv ib tug lev ntawm hlau fibers. Cov fibers yog sintered ua ke los tsim ib tug ntxeem tau nruab nrab uas zoo heev rau high-kub thiab high-viscosity daim ntaub ntawv.

7. Sintered Hlau Hmoov Mesh:

Hom no yog tsim los ntawm sintering hlau hmoov los ua ib tug ntxeem tau filtration nruab nrab. Nws yog feem ntau siv thaum pom zoo thiab cov av muaj peev xwm tuav tau siab.

Txhua hom no muaj nws qhov zoo thiab yog tsim los rau cov kev siv tshwj xeeb. Thaum xaiv lub sintered mesh lim, nws yog ib qho tseem ceeb uas yuav tau xav txog qhov xwm ntawm cov khoom raug lim, qhov xav tau qhov pore loj, kev ua haujlwm, thiab lwm yam tseem ceeb.

Yuav Ua Li Cas Xaiv Txoj Cai Sintered Mesh Lim rau Koj Cov Khoom Pom Zoo?

Xaiv txoj cai sintered mesh lim rau koj cov cuab yeej pom yog qhov tseem ceeb rau kev ua haujlwm zoo. Nov yog cov lus qhia ib kauj ruam los ntawm kauj ruam los pab koj txiav txim siab paub:

1. Txiav txim siab yuav tsum tau lim:

* Particle Size: Nkag siab qhov me me me me uas koj xav tau lim tawm. Qhov no yuav coj koj xaiv qhov pore loj ntawm sintered mesh.

* Flow Rate: Xav txog qhov xav tau txaus tus nqi los ntawm lub lim. Qee hom mesh tso cai nrawm nrawm dua yam tsis muaj kev cuam tshuam pom kev ua haujlwm.

2. Txheeb xyuas cov xwm txheej ua haujlwm:

Kub: Xyuas kom cov sintered mesh xaiv tuaj yeem tiv taus qhov kub thiab txias ntawm koj cov txheej txheem.

Siab: Qee cov txheej txheem filtration cuam tshuam nrog kev kub siab. Xaiv ib lub mesh uas tuaj yeem tswj cov kev ntxhov siab no yam tsis muaj deforming.

Chemical Compatibility: Xyuas kom cov khoom ntawm lub mesh yog sib xws nrog cov khoom raug lim, tshwj xeeb tshaj yog cov tshuaj los yog cov khoom corrosive koom nrog.

3. Kev xaiv cov khoom siv:

Stainless hlau yog cov khoom siv tshaj plaws rau sintered mesh vim nws cov kav ntev thiab tsis kam tiv thaiv corrosion. Txawm li cas los xij, lwm cov ntaub ntawv xws li titanium lossis Monel yuav tsim nyog rau cov ntawv thov tshwj xeeb.

4. Xaiv hom Sintered Mesh:

Ib Txheej vs. Ntau txheej: Ntau txheej meshes muab lub zog ntau dua thiab pom meej dua tab sis tej zaum yuav dhau mus rau qee qhov kev siv.

Woven vs. Non-Woven (Fiber Felt): Thaum woven meshes muab cov pore ntau thiab tsawg, cov uas tsis yog-woven, zoo li fiber ntau, muab kev pom tob dua.

5.Xav saib xyuas thiab tu:

Koj yuav tsum tau ntxuav lossis hloov cov lim dej ntau npaum li cas? Qee cov sintered meshes tuaj yeem rov qab tau yooj yim, thaum lwm tus yuav xav tau kev hloov pauv tom qab qee lub sijhawm.

6. Txheeb xyuas qhov ntsuas ntsuas:

Kev pom kev ua haujlwm zoo, qhov ntsuas siab tawg, thiab permeability yog qhov tseem ceeb rau kev xav. Xyuas kom cov mesh xaiv tau raws li lossis tshaj qhov kev ntsuas uas xav tau rau koj daim ntawv thov.

7. Tham nrog cov neeg tsim khoom lossis cov kws tshaj lij:

Kev koom tes nrog sintered mesh lim chaw tsim khoom lossis ib tus kws tshaj lij tuaj yeem muab kev nkag siab zoo. Lawv tuaj yeem hais qhia cov khoom tshwj xeeb lossis cov kev cai daws teeb meem raws li koj xav tau.

8. Kev txiav txim siab nqi:

Thaum nws yog ib qho tseem ceeb kom tau txais cov lim uas ua tau raws li koj cov kev xav tau, nws kuj tseem ceeb heev kom sib npaug zoo nrog tus nqi. Xav txog ob qho tib si thawj zaug peev thiab cov nqi ua haujlwm ntev.

9. Daim ntawv pov thawj thiab kev pov hwm zoo:

Xyuas kom cov chaw tsim khoom ua raws li cov qauv zoo xws li ISO daim ntawv pov thawj. Qhov no lav qhov kev ntseeg tau thiab kev ua tau zoo ntawm sintered mesh lim.

Los ntawm ua tib zoo ntsuam xyuas koj cov kev xav tau thiab kev sab laj nrog cov kws tshaj lij, koj tuaj yeem xaiv txoj cai sintered mesh lim uas ua kom pom tseeb thiab siv tau ntev.

Sintered yaj Mesh lim vs Sintered ntxeem tau hlau lim?

Sintered melt mesh lim thiab sintered ntxeem tau hlau lim ua haujlwm sib txawv, txawm hais tias ob qho tib si yog ua los ntawm cov txheej txheem sintering.

Sintered Melt Mesh Lim:

* Qauv: Muaj cov woven hlau hlau uas sintered ua ke los ua ib lub mesh.

* Daim ntawv thov: Feem ntau siv rau kev pom cov khoom loj dua thiab ua ib qho kev txhawb nqa nruab nrab rau lwm lub tshuab pom.

* Qhov loj me: Feem ntau muab cov pore loj dua qhov tsim nyog rau kev pom ntxhib.

* Lub zog: Muab cov khoom siv dag zog zoo thiab feem ntau siv rau hauv cov ntawv thov uas ua haujlwm ntev yog qhov tseem ceeb.

Sintered Porous Hlau Lim:

* Qauv: Ua los ntawm cov hmoov hlau sintered, ua rau muaj kev sib txuam ntau dua thiab sib cuam tshuam pore qauv.

* Daim ntawv thov: Qhov zoo tshaj plaws rau kev pom zoo thiab cov roj pom, muaj peev xwm ntes cov khoom me me.

* Qhov loj me: tuaj yeem tsim kho rau qhov loj me me, tso cai rau kev tswj xyuas qhov tseeb.

* Ntau yam: Haum rau ntau yam kev siv, suav nrog kua thiab roj pom hauv ntau yam lag luam.

Hauv cov ntsiab lus, qhov kev xaiv ntawm ob yog nyob ntawm qhov kev pom zoo, xws li qhov loj me, cov nqi ntws, thiab hom ntawv thov.

Ntawm no peb ua ib lub rooj sib piv rau sintered yaj mesh lim thiab sintered ntxeem tau hlau lim:

| Feature | Sintered Melt Mesh Lim | Sintered Porous Hlau Lim |

|---|---|---|

| Qauv | Woven hlau hlau sintered ua ke | Sintered hlau hmoov |

| Daim ntawv thov | Coarse pom, txhawb nruab nrab | Fine filtration, gas pom |

| Pore Loj | Cov pore loj dua | Engineered rau cov pore qhov ntau thiab tsawg |

| Lub zog | Zoo mechanical zog | High durability thiab kuj |

| Lim Efficiency | Tsawg efficiency rau cov khoom me me | High efficiency rau cov khoom me me |

| Ntau yam | Txwv rau cov ntawv thov tshwj xeeb | Haum rau ntau yam kev lag luam |

| Kev tu | Yooj yim ntxuav | Muaj peev xwm ntxuav tau siv ntau txoj kev |

Daim ntawv thov

Nov yog qee qhov kev siv nrov ntawm sintered mesh lim, nrog rau cov lus piav qhia ntxaws rau txhua tus:

1. Pharmaceutical thiab Biotech Production:

* Nqe lus piav qhia: Hauv kev lag luam kws tshuaj thiab biotech, khoom purity yog qhov tseem ceeb. Sintered mesh cov ntxaij lim dej ua lub luag haujlwm tseem ceeb hauv kev ua kom qhov kev huv huv no los ntawm kev tshem tawm cov impurities thiab cov kab mob. Lawv siv nyob rau hauv daim ntawv thov xws li tsis muaj menyuam tsis taus cua pom, qhov cua, thiab cell culture media npaj. Lawv cov khoom tsis muaj zog thiab muaj peev xwm ua kom tsis muaj menyuam ua rau lawv zoo tagnrho rau cov ntawv thov rhiab, ua kom cov khoom sib xws thiab kev nyab xeeb ntawm tus neeg mob.

2. Kev ua Petrochemical:

* Nqe lus piav qhia: Kev lag luam petrochemical ua cov kua dej ntau yam, ntau yam uas muaj kuab paug lossis muaj cov impurities. Sintered mesh lim tau zoo cais cov khoom tsis xav tau, ua kom muaj cov roj zoo, roj nplua nyeem, thiab lwm yam khoom siv tshuaj. Muab lawv qhov kub thiab txias tsis kam, cov ntxaij lim dej no kuj zoo tagnrho rau kev ua haujlwm hnyav hauv kev lag luam no.

3. Kev tsim khoom noj thiab dej haus:

* Nqe lus piav qhia: Kev ua kom huv thiab kev nyab xeeb ntawm cov khoom siv yog qhov tseem ceeb tshaj plaws hauv kev tsim khoom noj thiab dej haus. Sintered mesh lim pab lim tawm cov khoom tsis xav tau, cov kab mob, thiab lwm yam kab mob los ntawm cov kua xws li kua txiv hmab txiv ntoo, cawv, thiab syrups. Lawv kuj tseem siv tau rau hauv daim ntawv thov venting kom paub meej tias huab cua tsis muaj menyuam nkag mus rau hauv fermentation tso tsheb hlau luam lossis cov nkoj cia.

4. Kev kho dej:

* Nqe lus piav qhia: Kev nkag mus rau cov dej huv yog qhov tseem ceeb rau kev siv thiab kev lag luam. Sintered mesh lim pab tshem tawm cov khoom seem, kab mob, thiab lwm yam kab mob los ntawm cov dej, ua kom cov dej haus muaj kev nyab xeeb thiab kev kho dej khib nyiab zoo. Lawv cov kev tiv thaiv corrosion yog qhov tshwj xeeb tshaj yog thaum lim dej saline lossis tshuaj kho dej.

5. Fluidized txaj hauv kev ua tshuaj:

* Nqe lus piav qhia: Fluidized txaj yog siv rau hauv ntau yam txheej txheem tshuaj uas cov khoom yuav tsum tau muab tshem tawm hauv cov kua. Sintered mesh cov ntxaij lim dej ua kom cov huab cua tsis sib xws lossis cov dej ntws, ua kom cov khoom sib npaug sib npaug, uas yog qhov tseem ceeb rau cov tshuaj tiv thaiv zoo ib yam thiab cov khoom zoo.

6. Aerospace thiab Automotive Lim:

* Nqe lus piav qhia: Kev lag luam aerospace thiab automotive industries yuav tsum tau precision nyob rau hauv txhua feem, nrog rau pom. Sintered mesh lim yog ua haujlwm nyob rau hauv hydraulic systems, roj systems, thiab cua tshuab. Lawv lub peev xwm los tiv thaiv kev kub ntxhov thiab tiv thaiv corrosion ua rau lawv tseem ceeb hauv cov kev xav tau no.

7. Electronics thiab Semiconductor Manufacturing:

* Nqe lus piav qhia: Raws li kev siv thev naus laus zis, kev xav tau ntawm cov dej ntshiab thiab huab cua hauv cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob semiconductor ua qhov tseem ceeb dua. Sintered mesh cov ntxaij lim dej pab ua kom tiav qhov purity no los ntawm kev lim tawm cov sub-micron hais, kom ntseeg tau tias cov khoom siv hluav taws xob zoo tau tsim.

8. Breather Vents nyob rau hauv Equipment Enclosures:

* Nqe lus piav qhia: Cov khoom siv hauv tsev, xws li cov khoom siv hluav taws xob lossis cov khoom siv hluav taws xob, feem ntau yuav tsum tau 'ua pa' kom sib npaug los yog tso cua sov. Sintered mesh lim hauv cov pa ua pa kom ntseeg tau tias thaum huab cua nkag mus, cov kab mob xws li plua plav lossis ya raws tau khaws cia, tiv thaiv cov khoom siv sab hauv.

Txhua daim ntawv thov no qhia txog kev siv ntau yam thiab kev ua haujlwm ntawm sintered mesh lim, hais txog lawv qhov tseem ceeb thoob plaws ntau yam kev lag luam.

FAQ

Dab tsi yog cov khoom siv siv rau sintered mesh?

Cov ntaub ntawv muaj xws li stainless hlau, npib tsib xee, titanium, bronze, thiab ntau yam polymers.

Qhov kev xaiv ntawm cov khoom yog nyob ntawm tej yam xws li tshuaj lom neeg compatibility, kub tsis kam, thiab mechanical zog.

Dab tsi yog qhov zoo ntawm sintered mesh lim?

Sintered mesh lim muaj ntau qhov zoo, suav nrog:

* Siab porosity thiab ntws tus nqi

* Zoo heev filtration efficiency

* Durability thiab kev pab lub neej ntev

* Resistance rau corrosion thiab puas

* Customizable pore qhov ntau thiab tsawg rau cov ntawv thov tshwj xeeb

Daim ntawv thov

Dab tsi yog qee qhov kev siv rau sintered mesh lim?

Sintered mesh lim yog siv nyob rau hauv ntau yam kev lag luam, xws li:

* Kev ua tshuaj lom neeg

* Kev tsim tshuaj

* Kev ua zaub mov thiab dej haus

* Ib puag ncig pom

* Aerospace thiab kev tiv thaiv

* Cov khoom siv kho mob

Yuav ua li cas sintered mesh lim siv nyob rau hauv chemical ua?

Hauv kev ua tshuaj, sintered mesh lim yog siv rau:

* Kev lim dej kom tshem tawm impurities thiab kab mob

* Gas filtration los ntes cov teeb meem

* Catalyst txhawb rau cov tshuaj tiv thaiv

Manufacturing thiab Properties

Yuav ua li cas sintered mesh tsim?

Sintered mesh feem ntau yog tsim los ntawm cov txheej txheem suav nrog:

1.Powder npaj:

Hlau lossis polymer hmoov yog npaj nrog qhov xav tau particle loj faib.

2. Kev tsim kho:

Cov hmoov yog nias rau hauv cov duab uas xav tau siv lub pwm.

3.Sintering:

Cov khoom tsim yog rhuab mus rau qhov kub thiab txias kom khi cov khoom ua ke, tsim cov qauv ntxeem tau.

Yam dab tsi cuam tshuam qhov pore loj thiab porosity ntawm sintered mesh?

Qhov pore loj thiab porosity ntawm sintered mesh tuaj yeem tswj tau los ntawm:

* Particle loj:Cov me me feem ntau ua rau cov pores me me.

* Siab thaum tsim:Kev kub siab tuaj yeem txo qhov porosity.

* Sintering kub thiab sijhawm:Kub siab dua thiab ntev sintering lub sij hawm yuav ua rau kom porosity.

Yuav ua li cas lub zog txhua yam ntawm sintered mesh tuaj yeem txhim kho?

Lub zog txhua yam ntawm sintered mesh tuaj yeem txhim kho los ntawm:

* Siv cov khoom siv muaj zog

* Ua kom lub sintering kub

* Ntxiv tus neeg sawv cev txhawb nqa

Kev tu thiab tu

Yuav ua li cas sintered mesh lim yuav tsum ntxuav thiab tswj?

Kev tu thiab tu cov txheej txheem yog nyob ntawm daim ntawv thov tshwj xeeb thiab hom kev lim dej. Cov txheej txheem muaj xws li:

* Rov qab ntxuav:Rau cov kua filtration, yuam cov kua rov qab los ntawm lub lim nyob rau hauv qhov opposite direction.

*Sonication:Siv ultrasonic nthwv dej kom tshem tawm cov kab mob ntawm cov lim dej.

* Tshuaj ntxuav:Siv cov tshuaj ntxuav kom tsim nyog kom yaj lossis tshem tawm cov kab mob.

Dab tsi yog cov cim qhia tias sintered mesh lim yuav tsum tau hloov?

Cov cim qhia tias sintered mesh lim yuav tsum tau hloov muaj xws li:

* Nce siab poob

* Txo tus nqi ntws

* Pom kev puas tsuaj lossis hnav

* Txo pom kev ua haujlwm zoo

Hu rau US

Nrhiav rau tshwj xeeb pom kev daws teeb meem?

Hu rau HENGKO ncaj qha ntawmka@hengko.comrau OEM koj cov cim sintered mesh lim.

Cia peb ua haujlwm zoo ua ke!