-

Cylindrical 25 50 micron stainless hlau microns ntxeem tau hmoov sintered lim raj rau ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

316L Sintered stainless hlau lim cartridge rau roj sib cais

Cov tshuab lim siv sintered hlau lim cov ntsiab lus tau ua pov thawj los ua ib qho txiaj ntsig thiab kev lag luam rau lwm cov khoom sib cais susceptib ...

Saib nthuav dav -

Porous hlau lim raj rau thermal tswj refining thiab tshwj xeeb tshuaj | HENGKO

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Cov chaw tsim khoom lag luam customized sintered ntxeem tau hlau lim raj siv rau kev kho mob ...

HENGKO sintered cov ntxaij lim dej feem ntau yog siv rau kev ua kom huv thiab pom cov kua thiab roj, kev sib cais thiab rov qab ntawm cov khoom siv, cov khoom cua txias ...

Saib nthuav dav -

sintered lim stainless hlau lim lub tog raj kheej rau kev kho dej aeration / plua plav ntxiv ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

0.2um rau 90 micron 5 - 100mm siab hmoov los yog hlau mesh ntxeem tau sintered hlau sta ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Sintered hlau hmoov ntxeem tau 316l SS stainless hlau lim raj, 2 μm 5 7 10 15 20 30 ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

2 10 20 25 microns ntxeem tau SS 304/316L hlau sintered stainless hlau lim raj rau li ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Sintered hlau 316 stainless hlau lim kho mob micro lim raj rau kua thiab roj ...

Khoom Piav Qhia Cov khoom siv lim dej tau siv dav hauv metallurgical, tshuaj, tshuaj, aerospace, thiab aviation teb. Porous Hlau Media ...

Saib nthuav dav -

Hloov sintered micron ntxeem tau hlau stainless hlau lim cartridges rau roj / o ...

Stainless hlau sintered lim yog tsim los ntawm cov raj, lub tog raj kheej, cartridges, khob nrog flange, xov, thiab fasteners, thiab lwm yam ... Nruab rau hauv cov kav dej ...

Saib nthuav dav -

5 10 micron stainless hlau 316L sintered lim cartridge / lub tog raj kheej

HENGKO muaj ntau yam ntxeem tau hlau cartridge lim los yog kev cai-tsim cov kev pab cuam rau pom pom nyob rau hauv cov ntaub ntawv tseem ceeb (yuam lub ceev ceev ...

Saib nthuav dav -

sintered hlau hmoov stainless hlau lim cua compressor cua lim

HENGKO 5-micron sintered lim khob tuaj yeem hloov kho rau ntau yam kev siv thiab kev qhia tshwj xeeb. Cov khob tuaj yeem txuas rau ntau yam hlau thiab tsis yog ...

Saib nthuav dav -

Customized Loj 316 Stainless Hlau Lim rau Kev Kho Mob Micro Capillary Tube ntawm Kua Be ...

Khoom Piav Qhia Lub micron sintered lim cartridge txuas nrog cov roj ntws tswj lub rooj tsavxwm los ntawm cov ntawv tso tawm nitrogen. Lub sintered lim ca...

Saib nthuav dav -

Sintered lim cartridge zoo lav txias kos seamless stainless hlau lim ...

Khoom Piav Qhia HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm kub....

Saib nthuav dav -

Stainless hlau sintered ntxeem tau micro cua nano lim capillary raj rau roj diffusion ...

Wave welding nitrogen sintered lim cartridge cov khoom lag luam cov ntsiab lus: tuaj yeem ua rau cov cua ntws sib txawv, rau yoj vuam nitrogen hloov cov neeg siv khoom ...

Saib nthuav dav -

Kev cai stainless hlau 316L nitrogen gas lim raj rau ntau lub hom phiaj pom

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Tuam Tshoj Professional Chaw tsim tshuaj paus Customized nano capillary nitrogen raj rau txhuas-lub neej reflow ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

sintered hlau stainless hlau 316L ntxeem tau cua pom ua npuas ncauj lim tswm ciab

Stainless Hlau Sintered Bushes yog hmoov metallurgical qhov chaw, ib qho tseem ceeb sintered hlau lim khoom tsim los ntawm HENGKO. High quality ntawm no s ...

Saib nthuav dav -

Customized loj 316 stainless hlau lim kho mob micro capillary raj rau yoj solder ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

Sintered 0.5 7 10 15 30 60 micron ntxeem tau hlau stainless hlau lim capillary raj rau ...

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav

Vim li cas thiaj xaiv SinteredHlau Cov limRau Koj Cov Haujlwm Pom Zoo:

Sintered hlau limyog tsim los ntawm cov hmoov hlau uas nias thiab sintered (fused) los ua ib qho ntxeem tau,

khoom qauv. Cov lim dej no paub txog lawv lub zog siab, ua haujlwm ntev, thiab muaj peev xwm lim tawm cov khoom me me.

8 Lub ntsiab nta ntawm Sintered hlau lim

HENGKO muaj ntau yam hlau sintered lim khoom, suav nrog sintered stainless hlau, sintered bronze,

sintered mesh, thiab sintered titanium lim, hlau hmoov lim, sintered hlau limdiscs, thiab sintered stainless

hlaucov raj. Peb cov ntxaij lim dej yog tsim los rau cov ntawv thov uas yuav tsum tau muaj kev tiv thaiv corrosion, kub kub,

thiab high precision kev ua tau zoo.

1. Lub zog muaj zog:

Sintered hlau lim yog tsim los ntawm cov hmoov hlau, uas ua rau lawv muaj zog

thiab durability.

2. High-temperature Resistance:

Sintered hlau lim tuaj yeem tiv taus qhov kub thiab txias, ua rau lawv

haum rau qhov kub thiab txias ib puag ncig.

3. Corrosion Resistance:

Sintered hlau lim yog resistant rau corrosion thiab yuav siv tau nyob rau hauv corrosive

ib puag ncig.

4. Chemical Resistance:

Sintered hlau lim tiv cov tshuaj feem ntau, ua rau lawv haum rau tshuaj

ua daim ntawv thov.

5. High filtration Efficiency:

sintered hlau lim muaj ib tug zoo heev pore qauv, uas tso cai rau lawv mus

lim tawm cov khoom me me zoo.

6. Cov av muaj peev xwm tuav tau siab:

Sintered hlau lim muaj peev xwm ua kom av-tuav siab, txhais tau tias lawv tuaj yeem ua tau

lim cov kua dej ntau ua ntej lawv yuav tsum tau hloov.

7. Yooj yim ntxuav:

Sintered hlau lim tuaj yeem ntxuav tau yooj yim thiab rov siv dua, ua rau lawv raug nqi

nyob rau hauv ntev.

8. Versatility:

Sintered hlau lim tuaj yeem ua rau ntau yam duab thiab ntau thiab tsawg kom tau raws li cov kev xav tau tshwj xeeb

ntawm cov kev siv sib txawv.

Rau cov ntxaij lim dej ntxeem tau, stainless hlau yog qhov kev xaiv zoo tshaj plaws rau kev pom hauv kev ua tshuaj, roj av refining,

kev tsim hluav taws xob, kev tsim tshuaj, thiab lwm yam kev siv.

Rau HENGKO, tag nrhosintered lim ntsiabundergo nruj zoo kuaj ua ntej shipping, nrog rau pom efficiency

thiab kev tshuaj xyuas qhov muag. Peb cov sintered hlau lim muaj ntau dua particle tshem tawm efficiency, corrosion kuj, tsawg dua

kev poob siab, kev ntxuav yooj yim dua, thiab rov qab zoo dua piv rau lwm cov khoom siv hlau lim.

Yog tias peb qhov kev muab tam sim no tsis tau raws li koj qhov kev xav tau, thovtiv tauj pebnrog koj cov khoom, qhov ntev,

thiab daim ntawv thov xav tau.

Daim ntawv thov ntawmSintered limCov khoom

Sintered lim tau siv dav hauv kev lag luam, suav nrog kev ua tshuaj lom neeg, roj av refining, tsim hluav taws xob, thiab kev tsim tshuaj. Lawv yog cov zoo tagnrho rau siv nyob rau hauv daim ntaub ntawv uas yuav tsum tau ib tug high degree ntawm filtration efficiency, thiab qhov twg lub lim yuav tsum muaj peev xwm tiv taus kub, siab, thiab corrosive ib puag ncig. Qee qhov kev siv ntau tshaj plaws ntawm sintered lim khoom suav nrog:

Kev lim dej

Sintered hlau lim feem ntau yog siv los ua kua pom hauv ntau yam kev lag luam. Lawv muaj txiaj ntsig tshwj xeeb hauv cov ntawv thov uas cov kua tau lim yog nkig lossis muaj cov khib nyiab siab. Sintered lim tuaj yeem tshem tawm cov khoom me me li 1 micron, ua rau lawv zoo tagnrho rau kev siv hauv cov ntawv thov uas yuav tsum tau muaj kev pom zoo.

Fluidizing

sintered hlau lim kuj tseem siv tau rau cov ntaub ntawv fluidizing, qhov chaw uas lawv pab kom sib npaug faib cov pa roj los yog kua los ntawm lub txaj ntawm cov khoom siv. Qhov no yog tshwj xeeb tshaj yog pab tau nyob rau hauv daim ntawv thov xws li catalysis, qhov uas nws yog ib qho tseem ceeb los xyuas kom meej tias tag nrho cov reactants yog sib npaug zos faib.

Sparging

Sintered hlau lim kuj tseem siv tau rau cov ntawv thov sparging, qhov uas lawv pab qhia cov roj rau hauv cov kua. Qhov no yog tshwj xeeb tshaj yog pab tau nyob rau hauv daim ntawv thov xws li fermentation, qhov uas nws yog ib qho tseem ceeb los xyuas kom meej tias cov kua fermented yog zoo aerated.

Diffusion

sintered hlau lim kuj tseem siv tau rau kev siv diffusion, qhov uas lawv pab kom sib npaug faib cov pa los yog kua los ntawm daim nyias nyias. Qhov no yog tshwj xeeb tshaj yog pab tau nyob rau hauv daim ntawv thov xws li roj hlwb, qhov uas nws yog ib qho tseem ceeb los xyuas kom meej tias cov reactants yog sib npaug zos faib nyob rau hauv daim nyias nyias.

Nplaim Arrestor

Sintered hlau lim kuj tseem siv tau los ua cov nplaim taws, qhov chaw uas lawv pab tiv thaiv kev sib kis ntawm nplaim taws lossis tawg. Qhov no yog qhov tshwj xeeb tshaj yog siv rau hauv cov ntawv thov xws li refineries lossis tshuaj nroj tsuag, qhov twg cov ntaub ntawv flammable.

Gas Lim

sintered hlau lim kuj siv rau cov roj pom nyob rau hauv ntau hom kev lag luam. Lawv muaj txiaj ntsig tshwj xeeb hauv cov ntawv thov uas cov roj tau lim muaj cov dej noo siab lossis lwm yam kab mob. Sintered lim tuaj yeem tshem tawm cov khoom me me li 0.1 micron, ua rau lawv zoo tagnrho rau kev siv hauv cov ntawv thov uas yuav tsum tau ua kom pom kev ua haujlwm siab.

Khoom noj khoom haus thiab dej haus

Sintered hlau lim kuj tseem siv rau hauv ntau yam khoom noj thiab dej haus, nrog rau kev pom ntawm npias, cawv, thiab lwm yam dej haus. Lawv muaj txiaj ntsig tshwj xeeb hauv cov ntawv thov uas yuav tsum tau ua kom pom kev ua haujlwm siab, thiab qhov twg cov lim yuav tsum tuaj yeem tiv taus qhov kub thiab txias thiab qhov chaw corrosive.

Yog tias koj xav tau cov khoom lim sintered uas ua tau raws li cov khoom siv tshwj xeeb, qhov ntev, lossis cov ntawv thov, thov koj xav dawbtiv tauj peblos tham txog koj cov kev xav tau.

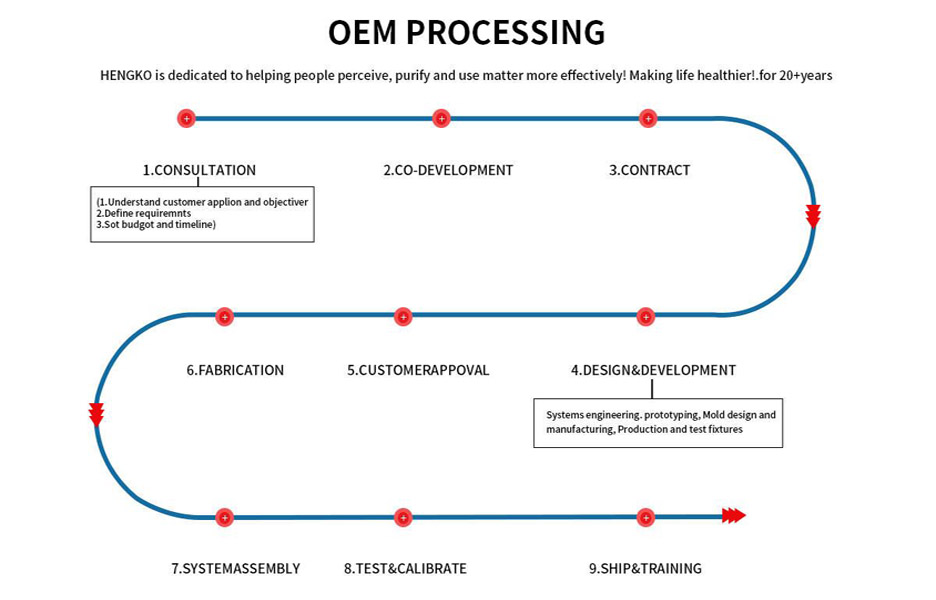

Customize Sintered Hlau Lim Txheej Txheem

Zoo siab txais tos coj koj cov kev xav tau tshwj xeeb cov ntxaij lim dej tiv tauj peb, peb yuav pom cov kev lim dej zoo tshaj plaws rau

koj cov kev xav tau filtration. thiabkoj tuaj yeem ua raws li cov txheej txheem dav dav kom ntseeg tau tias cov khoom kawg sib ntsib

tag nrho cov specifications tsim nyog. Cov txheej txheem suav nrog:

1.Kev sab laj thiab tiv tauj HENGKO

2. Co-Development

3. Ua Daim Ntawv Cog Lus

4. Tsim & Txhim Kho

5. Kev pom zoo rau cov neeg siv khoom

6. Fabrication / Mass Production

7. Kev sib dhos

8. Test & Calibrate

9. Kev xa khoom & Kev teeb tsa

Yog tias koj xav tau cov khoom lim sintered uas ua tau raws li cov khoom siv tshwj xeeb, qhov ntev, lossis cov ntawv thov,

thov hu rau peb los tham txog koj cov kev xav tau.

Dab tsi HENGKO Sib nrug hauv Sintered Hlau Lim Kev Lag Luam?

Vim li cas thiaj xaiv HENGKO's Sintered Hlau Lim?

HENGKO's sintered hlau lim tau txais txiaj ntsig zoo los ntawm peb cov neeg siv khoom rau lawv cov av tshwj xeeb tuav lub peev xwm thiab lub neej ntev.

Tsim los ntawm cov txheej txheem tswj sintering meticulously, cov OEM Sintered Hlau cov ntxaij lim dej muaj kev faib cov pores.

nrog micron ntsuasxws li ntawm 0.1μ mus rau 100μ, kom ntseeg tau meej thiab txhim khu kev pom pom.

Cov txiaj ntsig tseem ceeb ntawm HENGKO's Sintered Hlau Lim:

1.Stable thiab Durable Design:

Peb cov ntxaij lim dej muaj qhov ruaj khov zoo nrog kev ua haujlwm zoo rau kev cuam tshuam thiab kev hloov pauv,

ua rau lawv muaj zog heev txawm nyob rau hauv cov xwm txheej nyuaj.

2.Superior Cua Permeability:

Nrog kev ua haujlwm zoo sib xws, peb cov sintered hlau lim muab cov huab cua zoo permeability,

kom ntseeg tau tias kev ua tau zoo hauv ntau yam kev siv.

3.High Strength thiab Corrosion Resistance:

Tsim los tiv thaiv kev kub ntxhov thiab ib puag ncig corrosive, peb cov ntxaij lim dej muaj qhov tshwj xeeb unloading zog,

ua rau lawv zoo tagnrho rau kev thov kev lag luam chaw.

4.High-kub kev ua haujlwm:

Tshwj xeeb yog tsim rau high-temperature gas filtration,

peb cov sintered hlau lim ua tau kev ntseeg siab nyob rau hauv huab ib puag ncig.

5.Customization Options:

Peb muab cov kev daws teeb meem customized nrog ntau yam khoom siv, cov duab, thiab qhov sib txuas kom tau raws li cov kev xav tau tshwj xeeb.

Raws li cov chaw tsim khoom muaj npe nrov hauv Suav teb, HENGKO tshwj xeeb hauv kev tsim cov sintered hlau lim.

Peb pab neeg ntawm cov kws tshaj lij cov kws tshaj lij tau mob siab rau kev tsim kho thiab tsim khoom ntawm kev ua haujlwm siab

sintered stainless hlau thiab cov khoom ntxeem tau.

Txaus siab lees paub tias yog lub tuam txhab high-tech, HENGKO koom tes nrog cov tsev kawm qib siab hauv tsev

thiab thoob ntiaj teb kom tsis tu ncua innovate thiab txhim kho peb cov khoom.

4-Cov Lus Qhia Thaum Xaiv & OEM Sintered Hlau Lim Koj Yuav Tsum Saib Xyuas

Muaj ntau txoj hauv kev los kho cov sintered hlau lim kom tau raws li cov kev thov tshwj xeeb.

Qee txoj hauv kev muaj xws li:

1. Xaiv cov hlau tsim nyog:

Cov hlau sib txawv muaj cov khoom sib txawv uas tuaj yeem cuam tshuam raukev ua tau zoo ntawm cov

sintered hlau lim. Piv txwv li, stainless hlau yog corrosion-resistant thiab muaj ib tug siab melting point, thaum

aluminium yog lub teeb yuag thiab muaj hluav taws xob zoo conductivity.

2. Qhia qhov pore loj thiab cov duab:

Sintered hlau lim tuaj yeem tsim nrog cov pores ntawm ntau qhov sib txawv thiab

cov duab kom haum cov kev xav tau sib txawv. Piv txwv li, lub lim nrog me me pores yuav zoo dua ntawm kev tshem tawm

cov khoom me me, thaum lub lim nrog cov pores loj dua tuaj yeem tsim nyog rau cov nqi ntws siab.

3. Varying lub lim media thickness:

Lub thickness ntawm cov lim tawm kuj tuaj yeem hloov kho kom haum rau qhov tshwj xeeb

cov cai thov. Thicker media tuaj yeem muab kev pom zoo dua tab sis kuj tseem yuav ua rau siab dua

siab poob thiab txo tus nqi ntws.

4. Kho qhov kub thiab txias tej yam kev mob:

Sintered hlau lim tuaj yeem tsim los tiv thaiv tshwj xeeb

kub thiab siab tej yam kev mob, nyob ntawm daim ntawv thov. Nws yog ib qho tseem ceeb los xav txog cov xwm txheej no thaum twg

xaiv lub lim kom paub meej tias nws tuaj yeem tiv taus lub cev kev ua haujlwm.

Txhawm rau kho lub sintered hlau lim kom tau raws li koj cov kev xav tau tshwj xeeb, sab laj nrog tus kws tshaj lij engineers

lossis ib tus kws tshaj lij hauv kev ua haujlwm yuav pab tau. Lawv tuaj yeem coj tus qauv tsim nyog thiab xaiv cov khoom siv raws li

ntawm cov kev cai thov tshwj xeeb.

FAQrau Sintered Hlau Lim

1. Dab tsi yog Sintered Hlau Lim?

Lub ntsiab lus luv luv ntawm sintered hlau lim:Nws yog lub tshuab lim hlau uas siv cov hmoov hlau hlau ntawm tib qhov me me

kom zoo li tus stamping, high-temperature sintering yog txheej txheem ntawm metallurgy siv hmoov-loj

lub cev ntawm cov hlau sib txawv thiab alloys tom qab stamping.

Metallurgy tshwm sim los ntawm qhov sib txawv ntawm qhov kub thiab txias hauv qab lub melting point ntawm high-temperature furnaces. Cov hlau thiab alloys

Feem ntau siv niaj hnub no suav nrog txhuas, tooj liab, npib tsib xee, bronze, stainless hlau, thiab titanium.

Muaj cov txheej txheem sib txawv uas koj tuaj yeem siv los tsim cov hmoov. Lawv suav nrog kev sib tsoo, automation, thiab tshuaj decomposition.

Paub meej ntxiv txogDab tsi yog Sintered Hlau lim, thov mus saib peb cov kab lus no.

2. Vim li cas thiaj siv cov hlau tsis muaj hlau los ua lim?

Xaiv Cov Hlau Stainless Hlau ua cov ntaub ntawv tseem ceeb, tsuas yog vim muaj ntau yam txiaj ntsig rau stainless hlau

1. Tsis yooj yim rau xeb

2. Lub sintering kub tsis tas yuav tsum siab dhau

3. Cov pores yog yooj yim los tswj thaum lub sij hawm sintering

4. Sintered molding yog ntau ruaj thiab tsis yooj yim rau deform

5. Yooj yim ntxuav

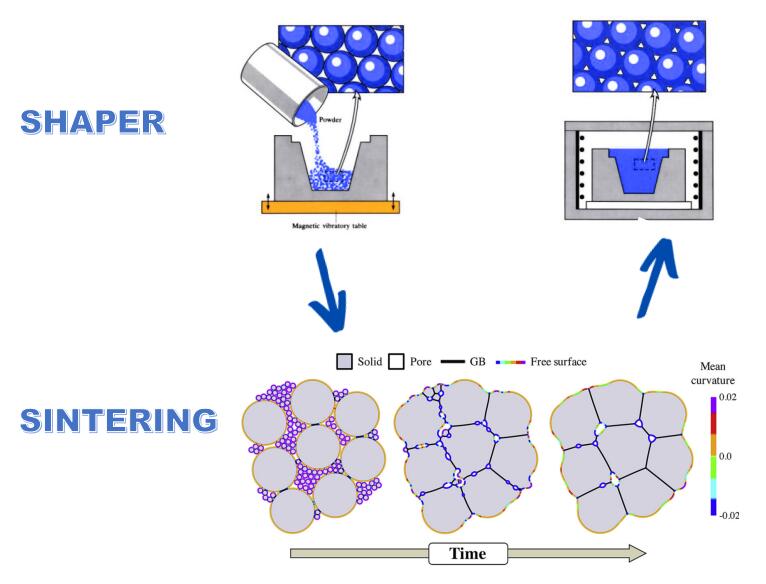

3. Sintered Hlau Lim Ua li cas?

Rau kev tsim cov txheej txheem ntawm Sintered hlau lim, lub ntsiab muaj 3-kauj ruam raws li hauv qab no:

A: Thawj kauj ruam yog kom tau txais lub zog hlau.

Cov hmoov hlau, Koj tuaj yeem tau txais cov hmoov hlau los ntawm kev sib tsoo, automation, lossis tshuaj decomposition. Koj tuaj yeem ua ke ib qho hlau

hmoov nrog lwm cov hlau los ua ib qho alloy thaum lub sij hawm fabrication, los yog koj siv tau tsuas yog ib tug hmoov. Qhov zoo ntawm sintering yog qhov ntawd

nws tsis hloov lub cev lub cev ntawm cov khoom siv hlau. Cov txheej txheem yog yooj yim heev uas cov ntsiab lus hlau tsis hloov.

B: Stamping

Cov kauj ruam thib ob yog nchuav cov hmoov hlau rau hauv cov pwm npaj ua ntej uas koj tuaj yeem tsim cov lim. Lub lim los ua ke yog tsim nyob rau hauv chav tsev

kub thiab nyob rau hauv stamping. Tus nqi ntawm lub siab thov nyob ntawm cov hlau koj siv, vim cov hlau sib txawv muaj qhov sib txawv elasticity.

Tom qab muaj kev cuam tshuam los ntawm kev kub siab, cov hmoov hlau yog compacted nyob rau hauv pwm los ua ib qho khoom lim. Tom qab cov txheej txheem kev kub ntxhov siab, koj tuaj yeem ua tau

tso cov hlau lim npaj rau hauv qhov cub kub kub.

C: Kub-kub sintering

Nyob rau hauv cov txheej txheem sintering, cov hlau hais yog fused los tsim ib chav tsev yam tsis tau mus txog lub melting point. Lub monolith no muaj zog,

nruj, thiab ntxeem tau lub lim raws li cov hlau.

Koj tuaj yeem tswj cov porosity ntawm cov lim dej los ntawm cov txheej txheem raws li qhov ntws ntawm cov huab cua los yog kua yuav tsum tau lim.

4. Cov txheej txheem ntawm Sintering yog dab tsi?

Ib kauj ruam tseem ceeb yog Sintering, yog li dab tsi yog txheej txheem ntawm sintering thiab ua hlau lim?

Koj tuaj yeem tshawb xyuas raws li daim ntawv qhia kom nkag siab meej.

5. Dab tsi yog Cov Lus Qhia Tseem Ceeb ntawm Sintered Hlau Lim?

Tom qab cov txheej txheem ntawm stamping thiab kub sintering, peb tuaj yeem tau txais cov sintered hlau lim, ces hauv

kom paub qhov zoo ntawm sintered lim, ib txwm, peb yuav sim qee cov ntaub ntawv ntawm cov lim dej, yog tias cov ntaub ntawv ncav cuag

cov kev xav tau raws li cov neeg thov, ces peb tuaj yeem tso tawm kom npaj xa tawm.

1. Porosity

2. Kev ntsuas compression

3. Flow test (gas and liquid)

4. Tshuaj tsuag ntsev (kev tshuaj tiv thaiv xeb)

5. Dimensional pom kev ntsuas

Yog tseem xav paub ntxivsintered lim ua haujlwm txoj cai, thov mus saib peb qhov blog tshawb xyuas cov ntsiab lus.

B:Daim ntawv thovntawm Sintered Hlau Lim

6. Daim ntawv thov ntawm Sintered hlau lim nyob qhov twg?

Raws li peb cov neeg siv khoom xa mus rau qee daim ntawv thov tseem ceeb ntawm sintered lim raws li hauv qab no:

1.) Kev lim dej2. Fluidizing

3. Sparging4. Kev nthuav dav

5. Nplaim Arrestor6. Gas Lim

7. Khoom noj khoom haus thiab dej haus

7. Kuv puas tuaj yeem siv sintered hlau lim nrog ntau hom roj?

Yog lawm, tab sis yuav tsum tau kho qhov tshwj xeeb qhov pore loj li cov roj, kuj tseem yuav tsum tau tswj xyuas, yog li

koj tuaj yeem txais tostiv tauj pebqhia rau peb paub koj cov ntsiab lus.

8. Lub Sintered Hlau Filter puas tuaj yeem ua haujlwm ntxiv txawm tias cov xwm txheej khov?

Yog, rau sintered hlau lim, xws li 316Lsintered stainless hlau limtuaj yeem ua haujlwm hauv qab

-70 ℃ ~ + 600 ℃, yog lirau feem ntau ntawm sintered lim tuaj yeem ua haujlwm hauv qab khov. tab sis yuav tsum xyuas kom meej

Cov kua thiab roj tuaj yeem ntws hauv qhov chaw khov.

9. Yam tshuaj twg tuaj yeem lim los ntawm Sintered hlau lim thiab tsis ua mob rau lub cev lim?

Peb kuaj feem ntau ntawm cov tshuaj uas tuaj yeem txav mus los ntawm cov khoom tshwj xeeb no yam tsis ua mob rau nws,

xws li phenol muab tias lawv tau tsim los siv cov khoom siv tshuaj lom neeg muaj zog.

1.) Acid

Cov kua qaub muaj zog: suav nrog sulfuric acid (H2SO4), nitric acid (HNO3), thiab hydrochloric acid (HCl).

Tsis muaj zog acids nyob rau hauv siab concentration, xws li acetic acid

B Lewis acid daws nrog cov tshuaj tshwj xeeb, xws li zinc chloride

2.) Lub hauv paus muaj zog:

suav nrog sodium hydroxide (NaOH) thiab potassium hydroxide (KOH)

Alkali hlau (xws li sodium) hauv lawv lub xeev hlauAlkali thiab alkaline ntiaj teb hlau hydrides

Cov ntsiab lus siab ntawm cov hauv paus tsis muaj zog xws li ammonia

3.) Cov khoom ua kom lub cev qhuav dej,

suav nrog cov ntsiab lus siab sulfuric acid, phosphorus pentoxide, calcium oxide,

zinc chloride (non-solution), thiab alkali hlau ntsiab

4.) Cov khoom muaj zog oxidizing,

suav nrog hydrogen peroxide, nitric acid, thiab concentrated sulfuric acid.

5.) Electrophilic halogens

xws li fluorine, chlorine, bromine, thiab iodine (cov ions ntawm halides tsis corrosive),

thiab electrophilic ntsev xws li sodium hypochlorite.

6.) Organic halides lossis halides ntawm cov organic acids, xws li acetyl chloride thiab benzyl chloroformateanhydride

7.)Cov tshuaj alkylatingxws li dimethyl sulfate

8.) Qee cov organic tebchaw

10. Yuav ua li cas ntxuav Sintered hlau lim?

Kev tu kom zoo yog qhov tseem ceeb los tswj kev ua haujlwm thiab kev ua haujlwm ntev ntawm sintered hlau lim.

Nyob ntawm daim ntawv thov-txawm yog siv roj lossis kua lim-txhua txoj kev ntxuav tuaj yeem ua haujlwm:

1.Blowback rau Gas Applications:

* Hauv cov tshuab lim roj, blowback yog ib txoj hauv kev siv los ntxuav sintered hlau lim.

Cov txheej txheem no suav nrog thim rov qab cov pa ntws los ntawm cov lim dej, tshem tawm cov khoom ntim khoom,

thiab tshem tawm cov lim xov xwm.

2.Backflush rau Liquid Applications:

* Rau cov kua lim dej, backflushing yog ib txoj kev tu kom zoo. Cov txheej txheem no thim rov qab cov dej ntws los ntawm lub lim kom tshem tawm cov kab mob sib kis thiab rov ua kom cov lim dej ua haujlwm.

3. Ultrasonic tu:

* Ultrasonic tu yog siv los tshem tawm cov khoom siv tsis zoo ntawm lub lim. Txoj kev no siv cov suab nrov tsis muaj suab nrov los tsim cov npuas microscopic hauv cov tshuaj ntxuav, uas zoo tshem tawm thiab tshem tawm cov kab mob ntawm cov lim dej.

4. Tshuaj ntxuav:

Txhawm rau tshem tawm cov kab mob tsis zoo, cov tshuaj ntxuav tes tuaj yeem ua haujlwm. Cov no yuav suav nrog:

* Cov kuab tshuaj ntxuav:

Siv cov kuab tshuaj uas tsim nyog los yaj thiab tshem tawm cov kab mob organic.

* Caustic Ntxuav:

Siv cov tshuaj alkaline los rhuav tshem thiab tshem tawm cov ntaub ntawv organic thiab inorganic.

* Acid Ntxuav:

Cov kua qaub yog siv los ua kom yaj cov pob zeb hauv av lossis oxides.

Dej thiab cua Flush:

Kev sib xyaw ua ke ntawm cov dej thiab cua tso tawm tuaj yeem siv los tshem tawm cov khoom seem thiab xyuas kom cov lim huv huv.

Cov txheej txheem ntxuav no pab txuas ntxiv lub neej ntawm sintered hlau lim, kom ntseeg tau tias lawv txuas ntxiv muab cov txiaj ntsig zoo.

thiab txhim khu kev qha pom nyob rau hauv ntau yam kev siv.

C:Cov ntaub ntawv xajSintered Hlau Lim

10. L Customize sintered hlau lim thaum Ordering los ntawm HENGKO?

Yog, Tseeb.

Peb tuaj yeem OEM Sintered Hlau Lim raws li koj qhov ua raws li cov lus qhia tshwj xeeb cov npe:

1. Qhov loj me

2. Kev ntsuas Micron

3. Tus nqi ntws

4. Lim xov xwm koj yuav siv

5. Txhua qhov loj me raws li koj tus qauv tsim

11. MOQ rau Lag luam wholesale sintered hlau lim los ntawm HENGKO yog dab tsi?

Raws li Tus Kws Tshaj Lij Sintered Filter Chaw Tsim Tshuaj, peb muaj qee hom kev xaiv xws li Sintered Lim Disc,

Sintered Lim Tube,Sintered Lim Phaj, Sintered Lim khob,Sintered Lim Mesh, Hais txog MOQ

yuav nyob ntawm kojtsim loj thiab pore loj thiab lwm yam, ib txwm peb MOQ yog li ntawm 200 -1000pcs / yam khoom raws li tus tsim.

12. Dab tsi ua rau HENGKO sintered hlau lim tshwj xeeb?

1.) HENGKO's sintered hlau lim yog txawv los ntawm kev sivtswv yim tswv yim

uas lav zoo ib yam pore qhov ntau thiab tsawg thiab tshwj xeeb cov qauv kev ntseeg siab.

2.) Tsis tas li ntawd, HENGKO muaj ntau yamcustomization xaiv, tso cai rau cov neeg siv khoom txiav

qhov porosity, cov khoom siv, thiab tsim kom haum rau lawv cov kev xav tau tshwj xeeb.

Case Study:

1. Case Study Spotlight:Muaj Gas Lim

Txhim kho kev ua tau zoo hauv Industrial Gas Lim nrog Customized Sintered Hlau Lim

Kev sib tw:

Ib qho kev lag luam roj ua lag luam tau ntsib teeb meem nrog kev txo qis hauv nws qhov kev pom,

ua rau muaj kev saib xyuas tsis tu ncua thiab kev poob qis.

Cov lim dej uas twb muaj lawm tsis tuaj yeem tswj cov khoom hnyav hnyav, ua rau muaj kev cuam tshuam thiab txo qis qis.

Kev daws:

HENGKO cov kws tshaj lij pom zoo kom hloov cov ntxaij lim dej uas twb muaj lawm nrog kev cai tsim sintered hlau lim lim.

rau siab particle load daim ntaub ntawv. Cov ntxaij lim dej no muaj qhov ua kom zoo dua qhov pore qauv thiab txhim kho durability,

tshwj xeeb engineered los lis cov kev xav tau ntawm industrial gas pom.

Qhov tshwm sim:

Cov sintered hlau lim tshiab tau muab sib xyaw ua ke rau hauv cov txheej txheem uas twb muaj lawm, txo qhov txhaws

teeb meem thiab txij nkawm zaus.

Cov ntxaij lim dej txhim kho tau muab 30% nce hauv tus nqi ntws thiab txhim kho kev ua haujlwm tag nrho.

Los ntawm kev siv HENGKO cov kev cai sintered hlau lim, cov khoom siv roj ua haujlwm tau ntsib ib qho cim.

Kev txhim kho hauv kev pom kev ua haujlwm zoo, txuas ntxiv lub neej lim dej, thiab txo qis kev ua haujlwm poob haujlwm.

Kev daws tsis tau tsuas yog txhim kho cov khoom tsim tau zoo xwb tab sis kuj tseem ua rau muaj txiaj ntsig zoo dua los ntawm kev txo qis

cov nuj nqis tu thiab xyuas kom tsis muaj kev cuam tshuam qhov system ua haujlwm.

Tseem Muaj Lus Nug Thiab Nyiam Paub Ntxiv Rau CovSintered Hlau Lim, Thov koj xav tiv tauj peb tam sim no.

Kuj Koj Ua TauXa email rau pebDirectly Raws li:ka@hengko.com

Peb yuav xa rov qab nrog 24-teev, Ua tsaug rau koj tus neeg mob!