-

High Quality Sintered Bronze Roj Lim

Product Details Qhia peb cov roj lim saum toj kawg nkaus nrog Sintered Bronze Fuel Element - qhov kev daws teeb meem zoo tshaj plaws rau txhua tus neeg uas xav tau lub siab zoo ...

Saib nthuav dav -

Sintered Copper Bronze Grounding Phaj

Deters Electrolysis thiab Galvanic CorrosionReduces RF cuam tshuam thiab txhim kho Electronics Performance Zoo txais tos rau koj cov khoom siv GPS, huab cua ...

Saib nthuav dav -

Porous Hlau Sintered Mini Lub tog raj kheej

Porous hlau yog ib qho ntawm ntau cov ntaub ntawv tsim nyog rau kev tsim cov bearings. Cov txiaj ntsig ntawm Sintered Mini Lub tog raj kheej Powdered hlau muaj cov lej loj ...

Saib nthuav dav -

Acid thiab Alkali Resistant Ntau 316L Porous Stainless Hlau Lim Sintered Filt ...

Khoom Piav Qhia HENGKO biomedical lim yog ua los ntawm 316L hlau hmoov sintered ntawm qhov kub thiab txias, nrog ib tug uniform porosity ntawm 0.2-0.5 um, corrosion resistance...

Saib nthuav dav -

CEMS Online Smoke Analyzer Gas Sampling Probe 44.5mm * 121mm ib qho Kev Tshawb Fawb Tshwj Xeeb

Cov Khoom Piav Qhia * Cov plua plav sib cais hauv cov txheej txheem * Rau cov plua plav ntau tshaj 3g / m3 * Loj active nto * Lub neej ntev * Tsawg sib txawv siab ...

Saib nthuav dav -

Porous hlau lim raj rau thermal tswj refining thiab tshwj xeeb tshuaj | HENGKO

HENGKO stainless hlau lim raj yog tsim los ntawm sintering 316L hmoov khoom los yog multilayer stainless hlau xaim mesh ntawm qhov kub thiab txias. Lawv tau w...

Saib nthuav dav -

316L SS stainless hlau hlau sintered lim, Customized microporous npib tsib xee monel inco ...

HENGKO cov ntaub ntawv hlau ntxeem tau yog tsim los ntawm kev kho cua sov ntawm ntau txheej stainless hlau xaim mesh lossis 316L hmoov ntawm qhov kub thiab txias. Cus...

Saib nthuav dav -

tswm ciab hom Sintered 316L stainless hlau mesh lim reusable cartridge

HENGKO muaj kev sau dav dav ntawm stainless hlau lim cartridges uas yog tsim los siv rau hauv ntau qhov kev lag luam, suav nrog petrochemicals ...

Saib nthuav dav -

Anti-corrosion Microns Powder Porous Sintered Hlau Lim Cartridge Rau Pom Qhov System

HENGKO tsim porous lim raj uas muaj versatility nyob rau hauv tsim raws li lawv muaj peev xwm hollow los yog dig muag nrog ib tug tsawg kawg nkaus phab ntsa thickness ntawm 1 hli. Cov khoom no yog c...

Saib nthuav dav -

sintered ntxeem tau hlau lim ntaub ntawv xov xwm, porosity 0.2 μm ~ 100 micron titanium mon ...

Ntawm HENGKO, cov txheej txheem ntawm kev tsim lawv cov ntaub ntawv hlau ntxeem tau muaj kev kho cua sov 316L cov khoom siv los yog ntau txheej stainless hlau hlau mesh ntawm siab t ...

Saib nthuav dav -

ntxeem tau hlau stainless hlau cartridge lim rau siab siab cua purification khoom ...

HENGKO tsim nws cov khoom siv hlau ntxeem tau los ntawm kev kho cua sov 316L cov khoom siv hmoov los yog ntau txheej stainless hlau xaim mesh ntawm qhov kub siab. Lawv...

Saib nthuav dav -

Kev txawj ntse 0.2 txog 120 microns micro porosity tooj dag inconel 316 316L stainless hlau ...

Porous hlau yog tsim los ntawm compressing hmoov hlau rau hauv ntau yam duab, uas yog ces sinter-bonded los tsim ib tug muaj zog thiab inert qauv. Qhov no ntau yam ...

Saib nthuav dav -

Sintered Bronze Lim nrog OEM Tshwj Xeeb Zoo rau Pom

HENGKO tuaj yeem muab cov neeg siv khoom muaj peev xwm ntawm kev tsim cov lim dej thiab cov khoom siv tooj liab nrog cov duab tshwj xeeb. Txhua daim ntawv thov tshwj xeeb r...

Saib nthuav dav -

5 10 20 90 120 microns sintered ntxeem tau hlau bronze stainless hlau 316L multi-purpose ...

HENGKO tsim cov khoom lim hauv ntau yam khoom, qhov ntau thiab tsawg, thiab fittings kom lawv tau yooj yim teev nrog cov yam ntxwv thiab configura ...

Saib nthuav dav -

Uniform lub zog sintered ntxeem tau hlau micron lim fluidizers bronze tooj dag tooj liab fil ...

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj kuab-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

sintered cua lim nruab nrab kheej kheej bronze lim caij

HENGKO SINTERED BRONZE OIL FILTER yog siv rau hauv sparging, sensor tiv thaiv, roj, thiab kua pom, dampening, bulk tuav thiab lwm yam uas rau lub solu ...

Saib nthuav dav -

Flow tswj thiab kua faib sintered lim phaj / ntawv, hmoov sintered ntxeem tau ...

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj kuab-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

Porous hlau sintered bronze tooj dag lim uniaxial thooj voos kheej kheej nrog ib qho kaw kawg nrog hex.

Cov lus piav qhia HENGKO tsim cov khoom lim hauv ntau cov ntaub ntawv, qhov ntau thiab tsawg, thiab cov khoom siv kom lawv tau yooj yim teev nrog cov charac ...

Saib nthuav dav -

Porous hlau sintered ntxeem tau bronze lim daim hlau / ntawv rau ntws thiab suab tswj

Qhov tob lim ntawv yog siv los tshem tawm cov khoom ntawm cov kua. Qhov no txhais tau hais tias cov kua tuaj yeem ua kom pom tseeb-, zoo- lossis tsis muaj kuab-filtered. Filter nplooj ntawv yog qhov zoo tagnrho rau ...

Saib nthuav dav -

Kev kho mob tshuaj kua roj thiab roj 3um-90 microns hmoov ntxeem tau tag nrho-hlau chav sint ...

HENGKO porous lim raj tuaj yeem yog qhov khoob lossis qhov muag tsis pom thiab muaj qhov tsawg kawg nkaus phab ntsa thickness ntawm 1 hli. Lawv yog tsim los ntawm isostatic compaction ntawm hmoov nyob rau hauv ib tug saj zawg zog mo...

Saib nthuav dav

Dab tsi yog Sintered Hmoov Hlau Lim thiab Cov Nta Tseem Ceeb

Sintered hmoov hlau lim yog ib hom lim ua los ntawm sintering, los yog cua sov, sib tov ntawm hmoov hlau

mus txog rau thaum lawv sib koom ua ke los tsim ib qho kev sib koom ua ke. Cov txheej txheem no tsim cov khoom ntxeem tau uas tuaj yeem ntxiab

Cov kab mob thiab lwm yam impurities, ua rau nws ua tau zoo lim rau ntau yam kev siv.

1. Hua porosity

Ib qho txiaj ntsig tseem ceeb ntawm sintered hmoov hlau lim yog lawvsiab porosity. Cov pores nyob rau hauv lub lim

me me, feem ntau yog qhov loj ntawm 0.2 txog 10 microns, uas tso cai rau lawv kom tshem tawm tau zoo

ntau yam kab mob los ntawm cov kua thiab roj. Nws ua rau lawv zoo tagnrho rau siv hauv tsheb,

aerospace, thiab kev kho mob kev lag luam, qhov twg huv si thiab purity yog qhov tseem ceeb.

2. Durability

Lwm qhov zoo ntawm sintered hmoov hlau lim yog lawvdurability. Cov txheej txheem sintering tsim ib

muaj zog, khoom qauv tiv taus hnav thiab tsim kua muag, tso cai rau lub lim kom tiv taus kev kub ntxhov thiab

kub tsis deforming lossis tawg. Nws ua rau lawv haum rau siv nyob rau hauv kev xav tau ib puag ncig,

xws li hauv cov cav tov lossis lwm cov tshuab ua haujlwm siab.

3. Yooj yim huv

Ib qho ntawm cov teeb meem ntawm kev siv sintered hmoov hlau lim yog tias lawv tuaj yeem ua taunyuaj los ntxuav thiab rov siv dua.

Vim tias cov pores me me heev, tshem tawm cov kab mob hauv lub lim yuav nyuaj, ua rau nws

tsim nyog los hloov lub lim es tsis ntxuav nws. Nws tuaj yeem raug nqi, tshwj xeeb tshaj yog rau cov ntawv thov uas qhov

lim yog siv ntau zaus. paub meej kuj muaj qee txoj kev los ntxuav.

Txawm hais tias qhov kev txwv no, sintered hmoov hlau lim tau dav siv vim lawv qhov ua tau zoo thiab ua haujlwm ntev.

Lawv yog cov khoom tseem ceeb hauv ntau cov txheej txheem kev lag luam thiab kev tsim khoom, uas pab ua kom muaj kev nyab xeeb

purity thiab zoo ntawm cov kua thiab gases. Nrog lawv lub peev xwm los cuab ntau yam kab mob thiab tiv taus

xav tau ib puag ncig, sintered hmoov hlau lim yog cov cuab yeej tseem ceeb rau kev tswj cov kev ua tau zoo

thiab kev ntseeg siab ntawm cov tshuab thiab khoom siv.

Vim li cas HENGKO Sintered Hmoov Hlau Lim

Muab Cov Kev Pom Zoo Pom Zoo

Peb hom sintered hmoov hlau lim cov kev daws teeb meem yog qhov zoo tshaj plaws hauv ntau yam kev thov;

ntxeem tau sinterhlau cov khoom tshwj xeeb yog siv nyob rau hauv ntau yam high-pressure sparging khoom rau ib tug nplua thiab

uniform faib ntawm gases rau hauv cov kua.

Porous sintered hmoov hlau lim, feem ntau nrog ntws-optimized loj cheeb tsam connectors, yog siv los cais

cov khib nyiab los ntawm cov kwj dej hauvntau yam txheej txheem. Lub ntsiab nta yog raws li nram no:

1. High-temperature kuj, Thermal stability mus txog 950 ° C

2. Haum rau kev sib txawv siab

3. Siab corrosion kuj

4. Cim sinter bonded connector

5. Cov qauv kev txhawb nqa tus kheej nrog cov neeg kho tshuab siab

6. Zoo heev rov qab mem tes ua haujlwm

7. Tsis muaj vuam ntawm ntxeem tau xov xwm

8. Tsim tau yooj yim, Ntau cov duab muaj, thiab kho

9. Ntau tshaj 10,000 ntau yam ntawm cov qauv thiab kev cai ntau thiab tsawg / duab muaj

10. Main Rau homogeneous gas/kua faib

11. Txais khoom noj khoom haus-chav kawm 316L thiab 304L stainless hlau lossis bronze

12. Ib qho yooj yim ntxuav thiab rov siv tau cov ntaub ntawv

PEB Technical

Raws li cov chaw tsim khoom lag luam zoo tshaj plaws ntawm cov khoom lag luam ntxeem tau zoo, HENGKO muaj cov txheej txheem thev naus laus zis thev naus laus zis.

rau high-temperature thiab corrosive ib puag ncig.

Feem ntau sintered hmoov hlau lim ntsiab yog ua los ntawm stainless hlau, bronze, nickel-based alloys, thiab titanium thiab tuaj yeem

yuav seamlessly welded nrog ib co tshwj xeeb alloys rau customize rau ib tug txawv duab nrog ib tug threaded connector los yog cua nozzle.

Txhais pom los ntawm qhov tseeb pore loj faib.

Khoom siv xaiv

HENGKO muaj nyob rau hauv ntau yam ntaub ntawv.

Cov hmoov hlau tov ua rau tailoring tsim thiab yuav tsum tautus txheej txheem yuav tsum yooj yim.

Cov ntaub ntawv muaj:

1. Stainless hlau (tus qauv 316L),

2. Hastelloy,

3. Inconel,

4. Monel,

5. Nyiaj,

6. Titanium

7. Cov Alloys tshwj xeeb ntawm kev thov.

Daim ntawv thov

1. Gas Lim

Peb muab ntau yam khoom thiab cov kev daws teeb meem rau kev pom cov roj kub kub hauv cov ntawv thov kev lag luam, thiab kev ua haujlwm kub

feem ntau tshaj 750 ° C rau lub sijhawm ntev. Cov lim dej no feem ntau ua haujlwm hauv cov tshuab nruab nrog tsis siv neeg tu tus kheej

muaj peev xwm, thiab cov ntsiab lus lim yuav tsum muaj peev xwm rov tsim dua tshiab ntawm txhua lub voj voog. yog li ntawdcov sintered hmoov hlau lim

yog qhov kev xaiv zoo tshaj plaws, thiab tag nrho cov nta tuaj yeem ua tau raws li; Txoj kev ntawd, peb cov lim dej ntxeem tau siv ntau dua hauv cov pa roj

lim kev lag luam.

2. Sparging

Cov cuab yeej siv siab ntau xav tau cov khoom lim dej, xws li kev sib cuag roj-kua uas yuav tsum tau muaj rau cov tshuaj tiv thaiv: stripping, sib tov,

los yog diffusion. Hauv ntau lwm daim ntawv thov, peb pab koj ua kom cov txheej txheem ua tau zoo los ntawm kev pom zoo thiab tsim qhov zoo tshaj plaws

kev daws teeb meem raws li ntau yam muaj nyob hauv sparger units.

3. Kev lim dej

Peb kuj muab kev cai tsim thiab txhawb nqa nws tus kheej yaj lim cov ntsiab lus mus rau lub lim dej ntawm 0.1µm hauv cov kua. Cov

sintered hmoov hlau lim tuaj yeem tsim nrog ob lub sandwich, thiab ob sinter-txuas hmoov qib muab

Kev sib haum xeeb thiab homogeneous tso tawm thiab txhim kho ntws piv rau cov lim dej uas tsim los. Cov sintered

porous disc yog cov lim zoo meej rau cov txheej txheem uas muaj cov catalyst. Peb sintered hmoov hlau lim ntsiab muaj a

lub neej dhau los ntawm kev sib tw feem ntau cov kev daws teeb meem vim tsis muaj kev sib txuas nrog kev sib txuas "khoom-khoom".

4. Fluidizing

Peb muab rau customize fluidizing khoom rau tshiab thiab uas twb muaj lawm industrial systems los ntawm tediously tswj txawv

tsim los ntawm kev tsim cov lim dej kom ntseeg tau tias cov pa roj zoo tshaj plaws uas ua rau muaj qhov zoo tshaj plaws hauv huab cua los yog sib xyaw rau ntau yam

cov xov xwm sib txawv, suav nrog bronze, stainless hlau, thiab polyethylene. Tsis tas li ntawd, vim fluidizing cones ua los ntawm

ruaj khov sintered hlau cov ntaub ntawv feem ntau yog kev txhawb nqa tus kheej, feem ntau peb tuaj yeem muab cov lim dej txuas nrog flanges

raws li xav tau.

Peb tus khub

Txog tam sim no HENGKO tau ua haujlwm ntau txhiab lub tuam txhab los ntawm ntau qhov kev lag luam suav nrog chemistry thiab roj, zaub mov, kev kho mob thiab lwm yam

Kuj muaj ntau lub chaw ua haujlwm ntawm cov tuam txhab thiab tsev kawm ntawv rau cov neeg muab khoom lag luam mus sij hawm ntev. Vam tias koj yuav yog ib tug ntawm lawv,

tiv tauj peb hnub no yog tias xav tau.

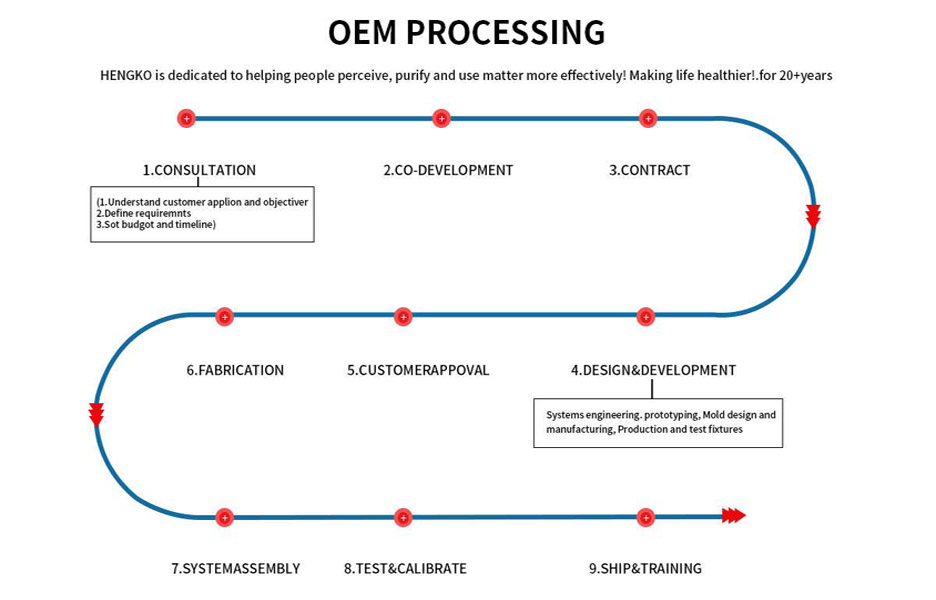

Yuav Ua Li Cas Customize Sintered Hmoov Hlau Lim Los Ntawm HENGKO

Thaum koj muaj qee yamTshwj xeeb tsim Sintered Melt Filterrau koj tej yaam num thiab nrhiav tsis tau ib yam los yog zoo Filter

khoom, Zoo siab txais toshu rau HENGKO ua hauj lwm ua ke los nrhiav kev daws teeb meem zoo tshaj plaws, thiab ntawm no yog cov txheej txheem ntawm

OEM Porous Melt FilterThov Saib thiabTiv tauj pebtham kom ntxaws ntxiv.

HENGKO tau mob siab rau pab tib neeg pom, ntxuav thiab siv cov teeb meem zoo dua! Ua lub neej noj qab nyob zoo tshaj 20 xyoo.

1.Kev sab laj thiab tiv tauj HENGKO

2.Co-Development

3.Ua Daim Ntawv Cog Lus

4.Tsim & Txhim Kho

5.Cov neeg siv khoom pom zoo

6. Fabrication / Mass Production

7. Qhov System Assembly

8. Test & Calibrate

9. Kev xa khoom

Yog li koj txoj kev lag luam yog dab tsi? thiab koj puas muaj lus nug txog cov hlau lim thiab xav kom peb nrog los yog kho

tshwj xeeb ntxeem tau hlau limrau koj lub cuab yeej thiab tshuab? Thov cia li xa tuaj rau peb nug, Peb pab neeg R & D yuav

tuaj yeem muab cov lus teb sai thiab txaus siab rau koj.

FAQ

1. Dab tsi yog sintering hauv hmoov metallurgy?

Sintering yog siv nyob rau hauv cov hmoov metallurgy los hloov cov hmoov hlau rau hauv cov khoom, cov khoom ntxeem tau. Cov txheej txheem no suav nrog

cua sov cov hmoov hlau mus rau qhov kub thiab txias hauv qab lawv cov ntsiab lus melting, uas ua rau cov khoom sib txuas

ua ke thiab tsim ib qho khoom siv.

Cov txheej txheem sintering feem ntau yog siv rau hauv kev tsim cov hlau thiab cov khoom siv, xws li cov kabmob, lub zog,

thiab lim. Nws muaj ntau yam zoo dua lwm txoj kev tsim khoom, xws li casting lossis forging, suav nrog

Cov nqi qis dua, kev tsim qauv yooj yim dua, thiab muaj peev xwm tsim cov duab thiab cov qauv tsim.

Thaum lub sij hawm sintering txheej txheem, cov hmoov hlau yog muab tso rau hauv pwm los yog tuag, uas txiav txim seb cov duab ntawm lub

ua tiav ib feem. Tom qab ntawd cov pwm yog muab tso rau hauv ib lub qhov cub, qhov chaw uas nws yog rhuab mus rau ib tug kub ntawm lub melting

ptshuaj pleev xim hlau. Raws li cov hmoov hlau yog rhuab, lawv pib sib koom ua ke thiab tsim ib qho khoom siv.

Raws li cov hmoov hlau sinter, cov pores ntawm cov khoom ua me thiab me. Nws tsim ib qho ntxeem tau

cov khoom siv uas muaj zog thiab ruaj khov tab sis kuj muaj thaj chaw siab, uas ua rau nws zoo tagnrho rau kev siv xws li

raws li kev pom thiab kev txhawb nqa catalyst. Nws tuaj yeem tswj qhov loj thiab kev faib tawm ntawm qhov pores los ntawm kev kho cov sintering

kub thiab lub sij hawm thiab muaj pes tsawg leeg ntawm cov hmoov hlau.

Thaum cov txheej txheem sintering tiav, cov khoom, cov khoom ntxeem tau raug tshem tawm ntawm pwm thiab tso cai rau

txias. Qhov tiav lawm tuaj yeem raug machined lossis ua tiav los tsim cov duab thiab loj.

Sintering yog txheej txheem ntau yam uas tuaj yeem tsim ntau yam hlau thiab cov khoom. Nws muaj ntau yam zoo,

nrog rau cov nqi qis, tsim kom yooj yim, thiab muaj peev xwm los tsim cov duab thiab cov qauv. Vim li ntawd,

sintering yog siv dav hauv kev tsim cov hlau thiab cov khoom siv hauv tsheb, aerospace, thiab

kev kho mob kev lag luam.

2. Vim li cas sintering tseem ceeb hauv hmoov metallurgy?

Sintering yog txheej txheem tseem ceeb hauv cov hmoov metallurgy vim nws khi cov khoom hauv cov hmoov hlau rau

tsim ib yam khoom, cohesive. Nws yog ua los ntawm cua sov cov hmoov mus rau qhov kub thiab txias hauv qab nws melting point,

uas ua rau cov khoom sib txuas los ntawm diffusion.

Sintering yog qhov tseem ceeb rau ntau yam:

1. Nws tso cai rau kev tsim cov khoom nrog cov duab nyuaj uas yuav nyuaj los yog tsim tsis tau

siv lwm txoj kev tsim khoom.

2. Nws tuaj yeem siv los tsim cov khoom nrog cov khoom siv kho kom zoo dua qub, xws li lub zog ntau dua

thiab hardness.

3. Sintering tuaj yeem tsim cov khoom ntxeem tau nrog cov porosity tswj, uas yog qhov zoo rau kev siv

xws li lim thiab catalysts.

Cov txheej txheem sintering feem ntau suav nrog cua sov cov hmoov mus rau qhov kub ntawm ib ncig ntawm 80-90%

ntawm nws melting point nyob rau hauv tej yam kev mob ntawm kev kub siab thiab ib tug tswj cua. Nws ua rau cov

particles rau diffuse rau ib leeg, tsim ib qho khoom loj. Cov txheej txheem sintering tuaj yeem tswj tau

los tsim ib tug ntau yam ntawm microstructures thiab mechanical zog, nyob ntawm seb cov kev thov tshwj xeeb.

Ib qho txiaj ntsig tseem ceeb ntawm cov hmoov hlau metallurgy yog tias nws tso cai rau kev tsim cov khoom nrog cov duab nyuaj

thiab meej tolerances. Nws yog vim tias cov hmoov hlau tuaj yeem tsim rau hauv ib qho duab uas siv ntau yam txuj ci,

xws li nias thiab sintering. Qhov kev hloov pauv no tso cai rau cov tuam txhab tsim cov khoom nrog cov duab geometry nyuaj

thiab meej qhov ntev, uas yog tsis yooj yim sua nrog rau lwm yam kev tsim khoom.

Hauv kev xaus, sintering yog txheej txheem tseem ceeb hauv cov hmoov metallurgy vim nws tso cai rau kev tsim cov khoom

nrog cov duab nyuaj, txhim kho cov khoom siv kho tshuab, thiab tswj cov porosity. Nws yog ib kauj ruam tseem ceeb hauv cov hmoov

metallurgy txheej txheem thiab enables manufacturers los tsim cov khoom zoo rau ntau yam kev siv.

Yog li yog tias tseem muaj Cov Lus Nug thiab Txaus Siab rau Sintered Powder Hlau Lim, Koj tuaj yeem txais tos

tiv tauj peb ntawm emailka@hengko.com thiab koj tseem tuaj yeem xa cov lus nug los ntawm kev ua raws li daim ntawv nug, peb yuav xa

rov qab rau hauv 24-teev.