Porous Metal meaning

Porous Metal yog dab tsi

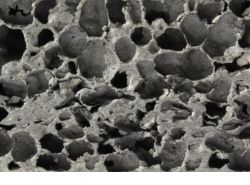

Hauv luv luv, Cov hlau ntxeem tau yog cov ntaub ntawv uas muaj peb-dimensional interconnected network ntawm pores, los yog voids, nyob rau hauv lawv cov microstructure uas tso cai rau cov kua los yog gases ntws los ntawm cov khoom.

Cov pores no muaj qhov loj ntawm nanometers mus rau millimeters thiab feem ntau yog tsim los ntawm cov txheej txheem xws li sintering, foaming lossis electroplating. Cov hlau ntxeem tau muaj cov khoom tshwj xeeb uas ua rau lawv muaj txiaj ntsig zoo hauv ntau yam kev siv, suav nrog kev pom, catalysis, lub zog cia, thiab biomedical engineering.

Lub porosity ntawm cov hlau no tuaj yeem tswj tau thiab tsim kom tau raws li cov kev xav tau tshwj xeeb, xws lipore loj, pore ntim, thiabthaj chaw saum npoo. Qhov no tunability tso cai rau tailoring porous hlau kom tau raws li cov kev xav tau ntawm cov kev siv sib txawv. Tsis tas li ntawd, cov txheej txheem sib txuas ntawm cov pore ntawm cov hlau ntxeem tau tso cai rau siab permeability thiab tsis tshua muaj siab poob, uas ua rau cov dej ntws thiab cov txheej txheem hloov loj.

Niaj hnub no,Porous hlauFeem ntau yog tsim los ntawm cov hlau engineering xws li txhuas, titanium, npib tsib xee thiab tooj liab, tab sis kuj tuaj yeem ua los ntawm cov khoom siv tsawg xws li magnesium lossis zinc. Cov khoom ntawm cov hlau ntxeem tau nyob ntawm seb hom hlau siv, kev tsim khoom, thiab qhov loj thiab kev faib tawm ntawm qhov pores. Cov hlau ntxeem tau tuaj yeem ua rau ntau yam ntaub ntawv xws li nplooj ntawv, raj, foams thiab hmoov, ua rau lawv muaj ntau yam khoom siv rau ntau yam kev siv.

Raws li nram no yog nrovdaim ntawv teev cov hlau ntxeem taudaim duab kos duab hauv kev ua lag luam, vam tias nws yuav ua rau koj paub meej txog cov hlau ntxeem tau.

Cov tshuaj Corrosion-Resistant rau Advanced Filtration thiab Gas Diffusion Applications

Porous Aluminium

Lub teeb yuag thiab ntau yam rau kev txhim kho cua sov hloov thiab acoustic attenuation

Ntshiab Nickel

High-Strength, High-Temperature Resistance, Zoo tagnrho rau Advanced Catalysis thiab Battery Applications.

Tus nqi-zoo tshuaj rau Precision Sintering thiab Tswj Porosity hauv Bearings thiab Lim.

Main Features & Advantage

Porosity:

Raws li lub npe qhia, cov hlau ntxeem tau yog tus cwj pwm los ntawm lawv cov kev sib txuas ntawm cov pores. Porosity tuaj yeem sib txawv nyob ntawm cov txheej txheem tsim khoom thiab thaj tsam li ntawm ob peb feem pua rau ntau tshaj 90%.

Qhov chaw saum npoo:

Cov hlau ntxeem tau muaj thaj tsam siab rau qhov ntim qhov sib piv vim lawv cov qauv ntxeem tau. Qhov no nce saum npoo yuav siv tau rau hauv daim ntawv thov xws li catalysis, pom thiab lub zog cia.

Mechanical zog:

Cov hlau ntxeem tau nthuav tawm ntau yam ntawm cov khoom siv kho tshuab, nyob ntawm cov khoom siv thiab cov porosity. Cov khoom siv ntawm cov hlau tuaj yeem raug kho los ntawm kev kho qhov pore loj, cov duab thiab kev faib tawm.

Biocompatibility:

Qee cov hlau ntxeem tau, xws li titanium thiab nws cov alloys, yog biocompatible thiab tuaj yeem siv rau hauv kev siv tshuaj biomedical xws li cog.

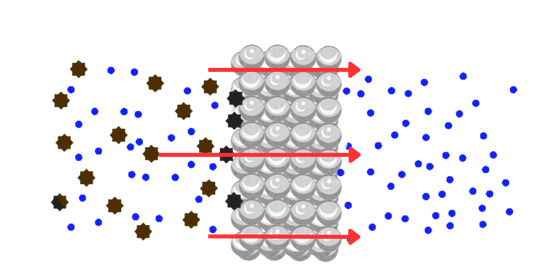

Cov kua dej ntws:

Kev sib txuas ntawm cov pores hauv cov hlau ntxeem tau tso cai rau cov kua dej ntws, ua rau lawv muaj txiaj ntsig zoo hauv kev siv xws li kev pom thiab kev sib cais.

Thermal thiab hluav taws xob conductivity:

Cov thermal thiab hluav taws xob conductivity ntawm cov hlau ntxeem tau tuaj yeem hloov kho los ntawm kev sib txawv ntawm cov porosity thiab hlau siv hauv cov txheej txheem fabrication.

High-Performance Lim nrog tswj qhov pore qhov loj me thiab qhov zoo tshaj plaws ntws rau cov roj thiab kua siv.

Durable thiab Wear-Resistant Cheebtsam rau Bearings thiab Hydraulic Systems nrog txhim khu lub lubrication Properties.

Kev daws teeb meem rau kev txhim kho cua sov thiab huab cua hloov pauv hauv cov txheej txheem tshuaj lom neeg thiab Petrochemical nrog kev ua haujlwm siab.

Kev daws teeb meem zoo tshaj plaws rau kev tsim & Engineering ntawm High Requires Filtration Problem

Ua ntej nkag siab, Peb Paub Sintered ntxeem tau hlau tuaj yeem muab ntau yamcustomizable flow thiab filtration zog. Thiab Cov khoom siv tshwj xeeb no yog tsim los ntawm sintering, uas muaj cov cua sov hlau hmoov rau qhov kub thiab txias hauv qab nws cov ntsiab lus melting, tso cai rau cov khoom kom fuse thaum tuav cov porosity xav tau. Koj tuaj yeem tsim nws yooj yim, tshuab nws, thiab tswj nws qhov porosity, ua rau nws muaj ntau yam khoom siv los tsim cov khoom lag luam tshwj xeeb lossis cov kev daws teeb meem uas koom nrog kev tswj hwm thiab tswj cov kua dej thiab roj.

Piv txwv tias koj tseem tab tom nrhiav qee yam khoom tshwj xeeb rau koj qhov system pom. Yog li ntawd, peb caw koj mustiv tauj pebniaj hnub no los tshawb nrhiav seb peb cov kev daws teeb meem hlau porous tuaj yeem pab daws koj cov teeb meem kev tsim engineering. Cia peb koom tes thiab txheeb xyuas cov kev daws teeb meem uas ua tau raws li koj qhov kev xav tau tshwj xeeb.

Daim ntawv thov rau Porous hlau

Cov hlau ntxeem tau thiab cov hlau ntxeem tau siv rau hauv ntau yam kev siv vim lawv cov khoom tshwj xeeb,

nrog rau siab permeability, tswj porosity, thiab mechanical zog. Hauv qab no yog qee yam kev siv:

1. Lim thiab sib cais:

Porous hlau lim tau dav siv nyob rau hauv industrial filtration systems, uas lawv pab cais cov khib nyiab los ntawm cov kua los yog gases.

Lawv muaj txiaj ntsig tshwj xeeb hauv kev lag luam xws li petrochemical, tshuaj ua haujlwm, thiab roj thiab roj vim lawv tsis kam mus rau qhov kub thiab txias thiab cov ntaub ntawv corrosive.

2. Sparging thiab Diffusion:

Nyob rau hauv sparging, ib tug ntxeem tau hlau yog siv los diffuse ib tug gas rau hauv cov kua, feem ntau aerate cov kua.

Qhov no feem ntau yog siv rau hauv kev kho dej khib nyiab, kev tsim tshuaj, thiab cov txheej txheem zaub mov thiab dej haus.

3. Kev Tswj Xyuas Siab:

Cov khoom siv hlau ntxeem tau tuaj yeem siv rau hauv kev tswj cov khoom siv siab xws li lub siab nyem li qub lossis lub tshuab nqus pa hauv ntau qhov kev lag luam xws li tsheb, aerospace, thiab cov tshuab ua haujlwm.

4. Sensors:

Cov hlau ntxeem tau siv tau rau hauv qee yam ntawm cov sensors vim lawv lub peev xwm tso cai rau cov pa roj thiab cov kua dej dhau mus.

Cov no tuaj yeem pom hauv kev saib xyuas ib puag ncig, kev ua lag luam, thiab kev siv kho mob.

5. Suab Damping:

Cov hlau ntxeem tau feem ntau siv rau lub suab damping lossis txo suab nrov hauv ntau qhov kev lag luam, los ntawm cov tshuab hluav taws xob tsheb mus rau kev siv tshuab.

6. Thaum tshav kub kub Exchangers:

Cov hlau ntxeem tau muab cov thermal conductivity zoo thiab cov yam ntxwv ntawm cov cua sov, ua rau lawv zoo heev rau kev siv hluav taws xob sib hloov, tshwj xeeb tshaj yog nyob rau hauv kev lag luam uas ua haujlwm nrog kub siab.

7. Catalyst Txhawb:

Hauv cov txheej txheem tshuaj, cov hlau ntxeem tau tuaj yeem siv los ua kev txhawb nqa catalyst, tso cai rau thaj chaw loj dua rau qhov tshwm sim. Qhov no feem ntau pom nyob rau hauv kev lag luam petrochemical.

8. Roj teeb Electrodes:

Cov hlau ntxeem tau tuaj yeem siv rau hauv kev tsim cov roj teeb electrodes. Lub porosity tso cai rau thaj tsam ntau dua, txhim kho lub roj teeb ua haujlwm.

9. Biomedical Applications:

Cov hlau ntxeem tau, tshwj xeeb tshaj yog ntxeem tau titanium thiab nws cov alloys, tau pom ntau daim ntawv thov hauv biomedical field, xws li hauv orthopedic implants thiab kho hniav implants. Lawv qhov ntxeem tau txhawb nqa pob txha ingrowth, ua rau kom zoo dua kev koom ua ke nrog lub cev.

10. Roj Cells:

Cov khoom siv hlau ntxeem tau tuaj yeem ua cov khoom siv hluav taws xob hauv cov roj hluav taws xob, tso cai rau cov pa roj kom yooj yim txav mus los thaum ua hluav taws xob.

Thov nco ntsoov tias qhov tshwj xeeb ntawm daim ntawv thov ntawm cov hlau ntxeem tau los yog cov ntxaij lim dej yog nyob ntawm hom porous hlau lossis alloy thiab qhov tseeb ntawm qhov porosity (qhov loj me, kev faib tawm, thiab kev sib txuas ntawm qhov pores).

yog li yog tias muaj lus nug rau daim ntawv thov ntawm porous sintered hlau lim, thov koj xav tias dawb rauhu rau HENGKOlos ntawm emailka@hengko.com.

FAQ Txog Porous Hlau

1. Vim li cas thiaj siv hlau ntxeem tau los ua lim?

Cov hlau ntxeem tau yog cov khoom siv nrog cov qauv tshwj xeeb uas muaj cov pores sib cuam tshuam los yog voids hauv nws cov khoom siv. Qhov pore loj thiab kev faib tawm tuaj yeem tsim kho kom tau raws li cov ntawv thov tshwj xeeb, ua rau nws muaj ntau yam khoom siv rau ntau yam kev lag luam.

Yog li ntawd, raws li cov haujlwm tshwj xeeb, cov hlau ntxeem tau feem ntau siv hauv kev tsim cov lim dej vim muaj ntau yam laj thawj:

1. Tswj Pore Loj:Cov hlau ntxeem tau tuaj yeem tsim kho kom muaj qhov pore meej heev. Qhov no tso cai rau kev tsim cov lim dej uas muaj peev xwm lim dej tshwj xeeb, xws li tshem tawm cov khoom ntawm ib qho me me.

2. Lub zog muaj zog:Cov ntxaij lim dej hlau muaj lub zog txhua yam, uas ua rau lawv muaj zog thiab ruaj khov. Lawv tuaj yeem tiv taus qhov kub siab thiab kub kub uas yuav ua rau lwm hom lim dej puas.

3. Chemical Resistance:Cov hlau feem ntau tiv taus ntau yam tshuaj, ua rau lawv haum rau siv nyob rau hauv ib puag ncig uas lawv yuav raug rau cov tshuaj corrosive.

4. Reusability:Cov ntxaij lim dej hlau tuaj yeem raug ntxuav thiab rov siv dua, uas yog ob qho tib si raug nqi thiab zoo ib puag ncig.

5. Thermal stability:Cov ntxaij lim dej hlau tuaj yeem txhawb nqa hauv cov ntawv thov kub, uas tej zaum yuav tsis yog cov ntxaij lim dej ua los ntawm cov ntaub ntawv polymer.

6. Permeability:Vim lawv qhov ntxeem tau, cov ntaub ntawv no tso cai rau cov kua dej txaus thaum khaws thiab khaws cov khoom zoo.

7. Backwash Peev Xwm:Cov ntxaij lim dej hlau tuaj yeem rov qab ntxuav kom tshem tawm cov khoom daig, uas tso cai rau rov qab cov ntaub ntawv tseem ceeb thiab ua kom lub neej ntev ntawm lub lim.

Li no, nyob ntawm daim ntawv thov thiab hom kua dej uas yuav tsum tau lim, cov ntxaij lim dej ntxeem tau yog qhov kev xaiv zoo heev.

2. Cov hlau ntxeem tau ua li cas?

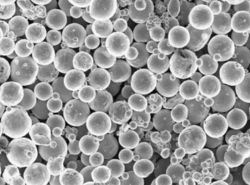

Cov hlau ntxeem tau feem ntau yog tsim los ntawm cov txheej txheem hu ua sintering, uas muaj cov cua sov hlau hmoov rau qhov kub thiab txias hauv qab nws cov ntsiab lus melting, cia cov khoom sib txuas ua ke thaum tswj cov porosity xav tau.

Cov txheej txheem ntawm kev ua cov hlau ntxeem tau tsim cov voids lossis pores hauv cov hlau. Muaj ntau txoj hauv kev siv los ua kom tiav qhov no, suav nrog hmoov metallurgy, sintering, thiab kev tsim khoom ntxiv. Hauv qab no yog cov lus piav qhia yooj yim ntawm ib txoj hauv kev, hmoov metallurgy:

1. Hlau hmoov ntau lawm:Thawj kauj ruam hauv kev tsim cov hlau ntxeem tau yog los tsim cov hmoov hlau. Qhov no tuaj yeem ua tau ntau txoj hauv kev, suav nrog atomization (txhaj cov kwj ntawm cov hlau molten rau hauv lub chamber uas nws solidifies rau hauv hmoov) los yog mechanical milling.

2. Mixing thiab Compacting:Cov hmoov hlau yog tov nrog ib tus neeg sawv cev los yog qhov chaw tuav cov khoom los pab tswj cov qauv thaum ua. Cov sib tov yog ces compacted nyob rau hauv siab siab nyob rau hauv ib tug tuag los tsim ib tug "ntsuab" compact. Cov duab ntawm qhov tuag yuav txiav txim siab qhov kawg ntawm cov hlau ntxeem tau.

3. Sintering:Lub ntsuab compact yog ces rhuab nyob rau hauv lub cub tawg mus rau ib tug kub ntawm lub melting point ntawm hlau. Cov txheej txheem no, hu ua sintering, ua rau cov khoom hlau sib txuas ua ke. Qhov kub thiab txias kuj ua rau cov ntaub ntawv los yog qhov chaw tuav cov ntaub ntawv hlawv tawm los yog evaporate, tawm hauv qab pores.

4. Txias thiab ua tiav:Tom qab sintering, cov hlau ib feem yog tso cai rau txias, ces nws yuav undergo cov txheej txheem ntxiv xws li xov los yog txheej los txhim kho nws cov yam ntxwv nto.

Lwm txoj hauv kev yog siv cov khoom siv ntxiv (feem ntau hu ua 3D luam ntawv), qhov twg cov hmoov hlau yog xaiv cov txheej txheej los ntawm txheej raws li tus qauv digital. Qhov no tuaj yeem tsim cov duab nyuaj thiab cov qauv hauv qhov pore uas yuav nyuaj lossis tsis yooj yim sua kom ua tiav nrog cov txheej txheem ib txwm muaj.

Qhov pore loj, kev faib tawm, thiab kev sib txuas tuaj yeem tswj tau ntau yam thaum lub sijhawm tsim khoom, uas ua rau cov hlau ntxeem tau haum rau ntau yam kev siv, suav nrog kev pom.

3. Dab tsi yog qhov zoo ntawm cov hlau ntxeem tau?

Qhov zoo ntawm cov hlau ntxeem tau muaj xws li qhov siab ntawm thaj tsam-rau-ntim piv, txhua yam muaj zog, thermal thiab hluav taws xob conductivity, thiab muaj peev xwm ua kom qhov pore loj thiab kev faib tawm. Cov khoom no ua rau nws muaj txiaj ntsig zoo hauv kev siv xws li catalysis, pom, thiab lub zog cia.

4. Cov kev txwv ntawm cov hlau ntxeem tau yog dab tsi?

Cov hlau ntxeem tau tuaj yeem muaj lub zog qis dua piv rau cov hlau tsis ntxeem tau vim muaj cov voids hauv cov khoom. Tsis tas li ntawd, cov txheej txheem tsim khoom tuaj yeem nyuaj thiab raug nqi.

5. Qhov txawv ntawm qhov qhib-cell thiab kaw-cell porous hlau yog dab tsi?

Qhib-cell porous hlau muaj kev sib txuas qhov pores uas nkag tau los ntawm qhov chaw ntawm cov khoom, thaum kaw-cell porous hlau tau kaw qhov pores uas tsis tuaj yeem nkag los ntawm qhov chaw.

6. Cov hlau twg tuaj yeem siv los ua cov hlau ntxeem tau?

Cov hlau ntxeem tau tuaj yeem tsim los ntawm ntau yam hlau, suav nrog txhuas, titanium, npib tsib xee, tooj liab, thiab stainless hlau, thiab lwm yam.

7. Dab tsi yog qhov kev siv ntawm cov hlau ntxeem tau?

Cov hlau ntxeem tau muaj kev siv hauv kev lag luam xws li aerospace, biomedical engineering, chemical processing, thiab lub zog cia, thiab lwm yam.

8. Cov teeb meem cuam tshuam nrog kev tsim cov hlau ntxeem tau yog dab tsi?

Cov teeb meem cuam tshuam nrog kev tsim cov hlau ntxeem tau suav nrog kev tswj xyuas qhov xav tau porosity, ua kom cov khoom siv kho tshuab zoo, thiab tswj cov pore loj thiab kev faib tawm.

9. Dab tsi yog qhov porosity ntawm cov hlau ntxeem tau?

Cov porosity ntawm cov hlau ntxeem tau tuaj yeem nyob ntawm ob peb feem pua txog 90% lossis siab dua, nyob ntawm cov ntawv thov.

10. Dab tsi yog qhov tseem ceeb ntawm qhov pore loj thiab kev faib tawm hauv cov hlau ntxeem tau?

Qhov pore loj thiab kev faib tawm hauv cov hlau ntxeem tau yog qhov tseem ceeb rau kev txiav txim siab ntawm cov khoom siv, xws li permeability, mechanical zog, thiab qhov chaw. Qhov no yog vim qhov pore loj cuam tshuam qhov yooj yim cov kua dej tuaj yeem ntws los ntawm cov khoom siv thiab ntau npaum li cas ntawm thaj chaw muaj nyob rau qhov tshwm sim.

11. Cov hlau ntxeem tau puas tuaj yeem hloov kho rau cov ntawv thov tshwj xeeb?

Yog lawm, cov hlau ntxeem tau tuaj yeem hloov kho rau cov ntawv thov tshwj xeeb los ntawm kev kho qhov pore loj thiab kev faib tawm, nrog rau hom hlau siv.

12. Lub neej ntawm cov hlau ntxeem tau yog dab tsi?

Lub neej ntev ntawm cov hlau ntxeem tau nyob ntawm daim ntawv thov thiab cov khoom siv tshwj xeeb. Feem ntau, cov hlau ntxeem tau muaj lub neej ntev vim lawv cov khoom siv siab thiab ua haujlwm rau corrosion.

13. Cov hlau porous puas tuaj yeem siv dua?

Yog lawm, cov hlau ntxeem tau tuaj yeem rov ua dua los ntawm cov khoom siv yaj thiab rov siv dua hauv cov ntawv thov tshiab.

14. Puas yog cov hlau ntxeem tau muaj kev nyab xeeb rau kev siv biomedical?

Qee hom hlau ntxeem tau, xws li titanium thiab tantalum, yog biocompatible thiab tuaj yeem siv nyab xeeb hauv kev siv biomedical. Cov qauv ntxeem tau tuaj yeem txhawb cov pob txha loj hlob thiab txhim kho kev koom ua ke nrog cov ntaub so ntswg ib puag ncig.

15. Yuav ua li cas cov hlau ntxeem tau kuaj rau lawv cov khoom?

Cov hlau ntxeem tau tuaj yeem raug sim rau cov khoom xws li porosity, permeability, thiab mechanical zog siv cov tswv yim xws li scanning electron microscopy (SEM), gas permeability tests, thiab compression tests.

Tshawb nrhiav qhov tsis muaj qhov kawg ntawm cov hlau ntxeem tau! Los ntawm kev txhim kho cua sov hloov mus rau kev pom zoo, cov hlau ntxeem tau muab cov txiaj ntsig tshwj xeeb uas tuaj yeem hloov pauv koj txoj kev lag luam. Tiv tauj peb hnub no kom paub ntau ntxiv thiab pib tshawb xyuas lub zog ntawm cov hlau ntxeem tau.

Txhua yam koj xav tau hu rau HENGKO tau txais kev daws teeb meem

Xa koj cov lus rau peb: