-

High-Capacity Stainless Hlau Inline Gas Lim rau Pharmaceutical Production

Kev piav qhia txheej txheem roj tshwj xeeb lim, tseem hu ua Point-to-Siv Inline Lim, yog tsim tshwj xeeb rau kev lag luam semiconductor kom meej meej ...

Saib nthuav dav -

Lub Siab Purity, High Pressure Gas Diffuser Solutions Tailored rau Semiconductor ...

Kev piav qhia Lub Diffuser Filter yog cov kev daws teeb meem tshwj xeeb uas tsim los rau cov ntawv thov cua nrawm hauv cov tshuab nqus tsev siv hauv cov txiv neej semiconductor ...

Saib nthuav dav -

High-Performance IGS Nto Mount C Foob Lim rau Semiconductor Gas Delivery Systems

Nqe lus piav qhia HENGKO Surface Mount Lim yog tsim los ua kom tau raws li qhov xav tau ntawm cov roj sib xyaw ua ke siv hauv cov khoom siv hluav taws xob semiconductor OEM. Muab...

Saib nthuav dav -

Porous Hlau Inline Point-of-Siv Lim rau Compressed Gas Applications

Kev piav qhia txheej txheem roj tshwj xeeb lim, tseem hu ua Point-to-Siv Inline Lim, yog tsim tshwj xeeb rau kev lag luam semiconductor kom meej meej ...

Saib nthuav dav -

High Pressure Gas Diffusers Ua rau Kev Lag Luam Semiconductor: Precision Pom ...

Kev piav qhia Lub Diffuser Filter yog cov kev daws teeb meem tshwj xeeb uas tsim los rau cov ntawv thov cua nrawm hauv cov tshuab nqus tsev siv hauv cov txiv neej semiconductor ...

Saib nthuav dav -

Kev Cai IGS Nto Mount C Foob Lim rau Advanced Gas Delivery Systems hauv Semiconduc ...

Nqe lus piav qhia HENGKO Surface Mount Lim yog tsim los ua kom tau raws li qhov xav tau ntawm cov roj sib xyaw ua ke siv hauv cov khoom siv hluav taws xob semiconductor OEM. Muab...

Saib nthuav dav -

Stainless Hlau Inline Porous Lim rau Compressed Cua thiab Gas Systems

Kev piav qhia txheej txheem roj tshwj xeeb lim, tseem hu ua Point-to-Siv Inline Lim, yog tsim tshwj xeeb rau kev lag luam semiconductor kom meej meej ...

Saib nthuav dav -

High Pressure High Purify Gas Lim rau Semiconductor Kev Lag Luam HF series los ntawm HENGKO

Cov lus piav qhia Cov roj lim dej tshwj xeeb yog tsim tshwj xeeb rau kev siv hauv high-pressure, high-purity gas delivery systems thiab ultra-high-purity gas tubs ...

Saib nthuav dav -

HENGKO® High Purity Semiconductor Gas Lim

High purity series lim yog tsim los lim semiconductor gases. Qhov no tag nrho welded los ua ke yuav xa 0.003 micron particle pab tuav. Ib nrab...

Saib nthuav dav -

Sintered In-line Hlau Gas Lim rau Semiconductor Gas Purification System

Sintered hauv-kab hlau roj lim ua haujlwm kom tshem tawm cov impurities xws li ya raws, oxygen, carbon dioxide, carbon monoxide, hydrocarbons thiab hlau carbonyls los ntawm ...

Saib nthuav dav -

HENGKO High Purity Porous Hlau Chamber Diffusers Pob zeb rau siab purity roj pom ...

HENGKO Porous Hlau Diffusers sai sai tso lub tshuab nqus tsev rau cov cua uas txo lub sij hawm voj voog thiab ua kom muaj zog ntxiv. Peb cov hlau stainless diffu...

Saib nthuav dav -

Kub thiab Humidity Sensor rau Semiconductor Clean Room Temperature Humidity Contr ...

Khoom Qhia Qhov kub thiab av noo ntawm qhov chaw huv si yog txiav txim siab raws li cov txheej txheem yuav tsum tau ua, tab sis nyob rau hauv cov xwm txheej ntawm kev sib ntsib ...

Saib nthuav dav -

Sintered SS 316L stainless hlau nplaim hluav taws tiv thaiv kev sojntsuam lim tsev muaj ...

Kev tawg-pov thawj sensor sib dhos yog ua los ntawm 316 stainless hlau rau kev tiv thaiv corrosion siab tshaj plaws. Lub sinter-bonded nplaim ntes muab cov roj diffusion ...

Saib nthuav dav -

316L nplaim-pov thawj lim tsev co2 semiconductor microns modbus sensor lim sojntsuam ho ...

HENGKO tawg-pov thawj sensor vaj tsev yog ua los ntawm 316L stainless hlau thiab txhuas rau kev tiv thaiv corrosion siab tshaj plaws. Lub sinter-bonded nplaim ntes muab ...

Saib nthuav dav

Semiconductor Gas Lim:

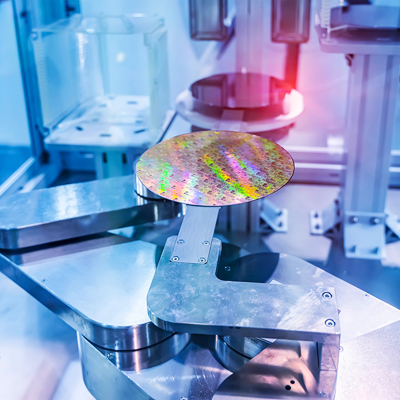

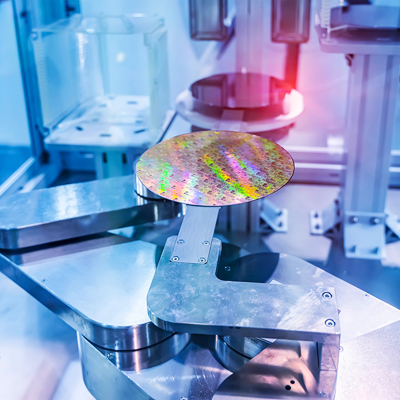

Ua kom ntseeg tau tias tsis muaj roj purity hauv Chipmaking

Nyob rau hauv lub ntiaj teb intricate ntawm semiconductor manufacturing, qhov precision thiab purity yog qhov tseem ceeb, qhov zoo ntawm

gases siv plays lub luag haujlwm tseem ceeb hauv kev txiav txim siab txoj kev vam meej. Cov impurities, txawm nyob rau theem infinitesimal,

tuaj yeem ua rau muaj kev puas tsuaj rau cov khoom siv hluav taws xob me me ntawm microchips, ua rau lawv tsis raug thiab siv tsis tau. Tiv thaiv

Cov txheej txheem tseem ceeb no, cov roj lim semiconductor sawv ua cov neeg saib xyuas tsis zoo, ua tib zoo tshem tawm cov kab mob.

thiab xyuas kom meej qhov zoo ntawm cov pa roj uas ntws los ntawm cov kab tsim khoom.

Muaj ntau yam zoo heev thiab cov txiaj ntsig ntawm sintered hlau lim

1. Crafted nyob rau hauv lub xeev-of-the-Art Cleanroom ib puag ncig

Cov ntxaij lim dej no tau yug los hauv lub xeev-ntawm-lub-kos duab cleanroom, ib puag ncig uas immaculate tej yam kev mob raug ceev ceev ceev kom txo tau tej yam kev kis kab mob. Lawv tau dhau los ua cov txheej txheem tsim khoom nruj, pib nrog precision vuam nyob rau hauv ib qho chaw ntawm huab cua huv. Tom qab deionized dej yaug, ua raws li lub siab-siab, lim nitrogen ntxuav, tshem tawm tej yam lingering hais thiab txo qhov kev pheej hmoo ntawm particle shedding.

2. Exceptional Particle Removal Efficiency

Nrog rau qhov zoo kawg nkaus pom kev ua haujlwm ntawm 9 LRV rau 0.003μm hais, ua raws li cov qauv nruj raws li SEMI F38 thiab ISO 12500 cov txheej txheem kuaj, cov ntxaij lim dej no tau txais txiaj ntsig zoo tshem tawm cov khoom siv hluav taws xob thiab cov khoom tsim tawm los ntawm cov khoom txav mus los, kom ntseeg tau tias cov purity pristine. cov pa.

3. Superior Mechanical Strength

Kev sim nruj heev los lav qhov tshwj xeeb resilience nyob rau hauv kev thov cov txheej txheem tsim khoom thiab ib puag ncig uas feem ntau siv cov roj cua siab, cov lim dej no muab kev ua haujlwm tsis muaj zog thoob plaws hauv lawv lub neej.

4. Ua tiav cov qauv kev lag luam siab tshaj plaws

Tshaj li cov kev cai nruj heev rau kev siv cov khoom siv hluav taws xob rau kev ua cov khoom siv semiconductor, cov lim dej no tau kuaj xyuas kom ntseeg tau tias lawv ua tau raws li qhov tseem ceeb pom kev ua haujlwm zoo, kev tswj xyuas meej meej, thiab cov qauv kev nyab xeeb uas xav tau los ntawm cov khoom siv roj hauv kev tsim khoom semiconductor.

5. Kev cog lus ruaj khov rau kev nyab xeeb

Txhawm rau tiv thaiv kom tsis txhob raug hluav taws kub hnyiab, corrosive, tshuaj lom, thiab cov txheej txheem pyrophoric gases, cov tsev lim dej tau raug kuaj xyuas kom zoo, kom ntseeg tau tias lawv ua tiav qhov xau zoo tshaj plaws ntawm tsawg dua 1x10-9 atm scc / thib ob. Qhov kev cog lus tsis txaus ntseeg no ua rau muaj kev nyab xeeb ua kom muaj cov pa phem uas muaj thiab tiv thaiv kom tsis txhob ua rau muaj kev puas tsuaj.

6. Uncompromising Purity rau Chipmaking Excellence

Los ntawm lawv qhov tshwj xeeb pom muaj peev xwm, tsis muaj kev cog lus rau kev nyab xeeb, thiab ua raws li cov qauv kev lag luam siab tshaj plaws, cov roj lim no ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv cov txheej txheem nyuaj ntawm kev tsim khoom semiconductor. Lawv sawv ua tus saib xyuas ntawm purity, kom ntseeg tau tias tsuas yog cov pa huv si ntws los ntawm cov kab tsim khoom, ua rau txoj hauv kev rau kev tsim cov microchips ua haujlwm siab uas ua rau peb lub ntiaj teb niaj hnub no.

Hom Semiconductor Lim

Semiconductor lim tau siv ntau yam kev siv, suav nrog:

* Kev tsim khoom Electronics:

Semiconductor lim yog siv los tshem tawm cov khoom los ntawm cov dej ntshiab, cov pa roj, thiab cov tshuaj siv hauv kev tsim khoom ntawm semiconductors.

* Tshuaj Mechanical Planarization (CMP):

Semiconductor lim yog siv los tshem tawm cov khoom los ntawm CMP slurries, uas yog siv los polish semiconductor wafers.

* Biomedical:

Semiconductor lim yog siv los tshem tawm cov khoom ntawm cov kua dej siv hauv kev kuaj mob thiab kev kho mob.

* Ib puag ncig:

Semiconductor lim yog siv los tshem tawm cov khoom ntawm huab cua thiab dej.

Muaj plaub yam tseem ceeb ntawm semiconductor lim:

1. Membrane lim:

Cov ntxaij lim dej membrane yog ua los ntawm cov yeeb yaj kiab nyias nyias, uas tso cai rau cov kua dej nkag mus rau hauv cov khoom thaum cov khoom khib nyiab.

2. Cov lim dej tob:

Cov lim dej tob yog ua los ntawm lub txaj tuab, tortuous ntawm cov khoom uas ntxiab hais thaum lawv ntws los ntawm cov lim.

3. Adsorbent lim:

Adsorbent lim yog tsim los ntawm cov khoom uas nyiam thiab tuav mus rau cov khoom.

4. Sintered hlau lim

Sintered hlau lim yog ib hom kev lim dej tob uas feem ntau siv hauv kev tsim khoom semiconductor. Lawv yog tsim los ntawm sintering zoo hlau hmoov rau hauv ib tug ntxeem tau qauv. Sintered hlau lim tau paub txog lawv cov kev ua haujlwm siab, kev ua haujlwm siab pom, thiab muaj peev xwm tiv taus qhov kub thiab txias.

Qhov zoo ntawm sintered hlau lim rau semiconductor manufacturing:

* High durability:

* High filtration efficiency:

* Ntev lifespan:

* Tshuaj compatibility:

Kev siv ntawm sintered hlau lim hauv semiconductor manufacturing:

* Gas purification:

Sintered hlau lim yog ib qho tseem ceeb ntawm cov txheej txheem tsim khoom semiconductor, pab kom paub tseeb tias cov khoom siv semiconductor zoo.

Hom semiconductor lim siv nyob rau hauv ib daim ntawv thov yog nyob ntawm qhov loj ntawm cov khoom raug tshem tawm, hom kua dej lim, thiab qib siab ntawm kev pom.

Ntawm no yog ib lub rooj hais txog ntau hom kev lim dej semiconductor:

| Hom lim | Kev piav qhia | Daim ntawv thov | Duab |

|---|---|---|---|

| Membrane lim | Ua los ntawm cov yeeb yaj kiab nyias nyias, uas tso cai rau cov kua dej hla dhau thaum cov khoom sib tsoo. | Electronics manufacturing, CMP, biomedical, ib puag ncig | |

| Cov lim dej tob | Ua los ntawm tuab, tortuous txaj ntawm cov khoom uas ntxiab hais thaum lawv ntws los ntawm lub lim. | CMP, biomedical, ib puag ncig | |

| Adsorbent lim | Ua los ntawm cov khoom uas nyiam thiab tuav mus rau cov khoom. | Electronics manufacturing, CMP, biomedical, ib puag ncig | |

| Sintered hlau lim | Ua los ntawm sintering nplua hlau hmoov rau hauv cov qauv ntxeem tau. | Gas purification, tshuaj pom, ultrapure dej pom, CMP slurry pom | Sintered hlau lim rau semiconductor |

Daim ntawv thov

Sintered hlau semiconductor roj lim tau dav siv hauv ntau yam kev siv hauv kev lag luam semiconductor. Lawv cov khoom tshwj xeeb, xws li kev pom kev ua haujlwm siab, ua haujlwm ntev, thiab muaj peev xwm tiv taus qhov kub thiab txias, ua rau lawv yog ib qho tseem ceeb ntawm cov roj xa khoom hauv kev tsim khoom semiconductor.

Nov yog qee qhov kev siv tshwj xeeb ntawm sintered hlau semiconductor roj lim:

1. Wafer ntau lawm:

Sintered hlau lim yog siv los ntxuav cov roj siv hauv cov khoom siv wafer, xws li nitrogen, hydrogen, thiab oxygen. Cov pa roj no tseem ceeb rau cov txheej txheem xws li kev loj hlob epitaxial, etching, thiab doping.

2. Tshuaj filtration:

Sintered hlau lim yog siv los lim cov tshuaj siv hauv semiconductor manufacturing, xws li acids, bases, thiab cov kuab tshuaj. Cov tshuaj no yog siv rau ntau lub hom phiaj, nrog rau kev tu, etching, thiab polishing.

3. Ultrapure dej pom:

Sintered hlau lim yog siv los lim dej ultrapure (UPW) siv nyob rau hauv semiconductor manufacturing. UPW yog qhov tseem ceeb rau kev ntxuav thiab yaug wafers, nrog rau kev npaj tshuaj.

4. CMP slurry pom:

Sintered hlau lim yog siv los lim CMP slurries, uas yog siv los polish semiconductor wafers. CMP yog cov txheej txheem tseem ceeb hauv kev tsim cov microchips.

5. Point-of-siv (POU) pom:

Sintered hlau lim feem ntau yog siv los ua POU cov ntxaij lim dej, uas tau ntsia ncaj qha rau ntawm qhov chaw siv los muab cov qib siab tshaj plaws ntawm kev pom. POU cov ntxaij lim dej yog qhov tseem ceeb tshwj xeeb rau cov ntawv thov uas qhov purity ntawm cov roj yog qhov tseem ceeb, xws li hauv kev tsim cov microprocessors thiab lwm yam khoom siv ua haujlwm siab.

6. High-purity gas tuav:

Sintered hlau lim yog siv nyob rau hauv high-purity gas tuav systems kom tshem tawm cov pa paug los ntawm gases siv nyob rau hauv semiconductor manufacturing. Cov kab mob no tuaj yeem suav nrog cov khoom, cov dej noo, thiab cov organic tebchaw.

7. Microelectronics manufacturing:

Sintered hlau lim yog siv rau hauv kev tsim cov microelectronics, xws li computers, ntsiav tshuaj, xov tooj ntawm tes, IoT sensors, thiab tswj cov cuab yeej.

8. Micro-electromechanical systems (MEMS) pom:

Sintered hlau lim yog siv nyob rau hauv MEMS pom, uas yog tus txheej txheem ntawm tshem tawm cov kab mob ntawm micro-electromechanical systems. MEMS yog siv nyob rau hauv ntau yam kev siv, nrog rau cov sensors, actuators, thiab transducers.

9. Cov ntaub ntawv cia khoom pom:

sintered hlau lim yog siv nyob rau hauv cov ntaub ntawv cia ntaus ntawv pom, uas yog tus txheej txheem ntawm tshem tawm cov kab mob ntawm cov ntaub ntawv cia li, xws li hard drives thiab solid-state drives.

Ntxiv rau cov ntawv thov tshwj xeeb no, sintered hlau semiconductor roj lim kuj tseem siv rau ntau yam kev siv hauv kev lag luam semiconductor. Lawv versatility thiab kev ntseeg tau ua rau lawv yog ib qho tseem ceeb rau cov tuam txhab semiconductor.

Nrhiav rau sab saum toj zoo sintered hlau semiconductor roj lim?

HENGKO yog koj mus-rau tus khub rau OEM kev daws teeb meem hauv semiconductor manufacturing systems.

Peb precision-engineered lim kom ntseeg tau thiab efficiency nyob rau hauv koj cov txheej txheem, muab koj lub ntug hauv kev sib tw ua lag luam.

Vim li cas thiaj xaiv HENGKO's Lim?

* Superior zoo thiab durability

* Customized daws teeb meem kom haum koj cov kev xav tau tshwj xeeb

* Txhim khu kev ua tau zoo rau kev tsim khoom semiconductor

Tsis txhob cia cov kev sib tw lim tuav rov qab koj cov khoom.

Hu rau peb hnub no los tshawb txog seb peb cov sintered hlau lim tuaj yeem hloov kho koj qhov kev tsim khoom.

Tiv tauj peb ntawmka@hengko.com

Koom tes nrog HENGKO thiab ua ib kauj ruam ntawm kev ua tau zoo hauv kev tsim khoom semiconductor!