-

Stainless hlau Sparger 2 Micron Stainless Hlau Carbonation Diffusion Pob zeb rau cov kab mob ...

Qhia HENGKO lub tswv yim tshiab sintered spargers - qhov kawg daws rau kev sib cuag roj-kua kua hauv ntau yam kev lag luam. Peb cov sparers siv koj ...

Saib nthuav dav -

Txhim kho ncaj nraim Porous hlau In-Line Sparger Tube tsim cov npuas me

HENGKO sintered spargers qhia cov pa roj rau hauv cov kua los ntawm ntau txhiab lub qhov hws me me, tsim cov npuas me me thiab ntau dua li cov yeeb nkab drilled ...

Saib nthuav dav -

Sintered ntxeem tau micron stainless hlau spargers homebrew wine wort npias cuab yeej bar acces ...

HENGKO sintered spargers qhia cov pa roj rau hauv cov kua los ntawm ntau txhiab lub qhov hws me me, tsim cov npuas me me thiab ntau dua li cov yeeb nkab drilled ...

Saib nthuav dav -

Micro Spargers nce kev hloov pauv roj thiab txhim kho Upstream Reactor Yields rau Bioreactors

Taw qhia HENGKO sintered spargers - qhov kawg daws teeb meem los qhia cov pa roj rau hauv cov kua tau yooj yim! Peb cov spargers tshiab muaj ntau txhiab tus me me po...

Saib nthuav dav -

Hlau Hauv Tank Porous Spargers kom nce roj nqus

HENGKO sintered spargers qhia cov pa roj rau hauv cov kua los ntawm ntau txhiab lub qhov hws me me, tsim cov npuas me me thiab ntau dua li cov yeeb nkab drilled ...

Saib nthuav dav -

Micro spargers npuas cua aeration pob zeb rau bioreactor los ua ke

Micro spargers los ntawm HENGKO txo cov npuas loj thiab ua kom cov pa hloov pauv kom txo tau cov roj noj thiab txhim kho cov khoom siv hluav taws xob sab saud. HENGKO spargers tuaj yeem nyob hauv ...

Saib nthuav dav -

Sintered stainless hlau 316L micro cua sparger thiab brewing diffuser carbonation ozone ...

Khoom npe Specification SFB01 D1 / 2 '' * H1-7 / 8 '' 0.5um nrog 1/4 '' Barb SFB02 D1 / 2 '' * H1-7 / 8 '' 2um nrog 1/4 '' Barb SFB03 D1 / 2'' * H1-7 / 8 '' 0.5u...

Saib nthuav dav -

316L stainless hlau ntxeem tau sparger raj sintered ntsis rau fermentation nkoj accessories

Txuas mus rau qhov kawg ntawm lub raj sparger, qhov no 316L stainless hlau sintered ntsis yog muaj nyob rau hauv ntau qhov ntau thiab tsawg pore. 5 10 15 50 100 pore frit yog qhov ...

Saib nthuav dav -

SFB02 2 microns sintered stainless hlau micro ntxeem tau cua diffusers spargers siv hauv kuv ...

Khoom npe Specification SFB02 D1 / 2 '' * H1-7 / 8 '' 2um nrog 1/4 '' Barb HENGKO carbonation pob zeb yog ua los ntawm cov zaub mov qib ...

Saib nthuav dav -

Nitrogenous wine Tool Diffusion Professional Zoo Aeration Pob Zeb Npias Brewage 316L ...

Khoom npe Specification SFB01 D1 / 2 '' * H1-7 / 8 '' 0.5um nrog 1/4 '' Barb SFB02 D1 / 2 '' * H1-7 / 8 '' 2um nrog 1/4 '' Barb SFB03 D1 / 2'' * H1-7 / 8 '' 0.5um...

Saib nthuav dav -

SFC02 2 micron MFL Carbonation Sparger Inline Diffusion Pob zeb rau bubbling dej / npuas ...

Hydrogen dej yog huv si, muaj zog, thiab nrog hydrogen. Nws pab ntxuav cov ntshav thiab ua kom cov ntshav txav mus. Nws tuaj yeem tiv thaiv ntau yam kab mob thiab txhim kho ...

Saib nthuav dav -

Sintered stainless hlau 316L micro cua sparger thiab brewing carbonation ozone npuas st ...

Sintered cua pob zeb diffusers feem ntau yog siv rau kev txhaj tshuaj porous. Lawv muaj qhov sib txawv pore qhov ntau thiab tsawg (0.5um rau 100um) cia cov npuas me me ntws los ntawm t ...

Saib nthuav dav -

Sintered stainless hlau 316L aeration carbonation pob zeb cua pob zeb ozone cua sparger 0....

HENGKO carbonation pob zeb yog ua los ntawm cov zaub mov qib zoo tshaj plaws stainless hlau khoom 316L, noj qab nyob zoo, tswv yim, ruaj, kub resistant, thiab anti-co ...

Saib nthuav dav -

Tsev brew npias cov khoom siv carbonation pob zeb cua sparger aeration pob zeb diffusion siv rau hydr...

Sintered cua pob zeb diffusers feem ntau yog siv rau kev faib roj thiab cua aeration. Lawv muaj ntau qhov pore qhov ntau thiab tsawg los ntawm 0.2 microns txog 120 microns pub ...

Saib nthuav dav -

Cua sparger npuas diffuser carbonation pob zeb muab txoj kev ceev tshaj plaws rau infusing ...

HENGKO Diffusion Stones, los yog 'Carbonations Stones', feem ntau yog siv los aerate lub wort ua ntej fermentation, uas yuav pab kom muaj kev noj qab nyob zoo pib fermen ...

Saib nthuav dav -

Stainless hlau 316L SFC04 tsev brew 1.5 "Tri Clamp haum 2 micron diffusion pob zeb ai ...

HENGKO sintered spargers qhia cov pa roj rau hauv cov kua los ntawm ntau txhiab lub qhov hws me me, tsim cov npuas me me thiab ntau dua li cov yeeb nkab drilled ...

Saib nthuav dav -

loj batch hydrogen permeation micro npuas ozone sparger diffuser rau diy tsev brewin ...

1. Zoo dua li tuav lub khob! 2. Puas yog koj nkees ntawm carbonating koj npias txoj kev tsis tuaj yeem? Koj crank up PSI hauv keg, co, thiab tos nrog ...

Saib nthuav dav -

Porous hlau txheej txheem lim, micro spargers rau hydrogenated roj manufacturing

Khoom Piav Qhia Sintered cua pob zeb diffusers feem ntau yog siv rau kev txhaj tshuaj porous. Lawv muaj qhov sib txawv pore qhov ntau thiab tsawg (0.5um rau 100um) pub me me bub ...

Saib nthuav dav

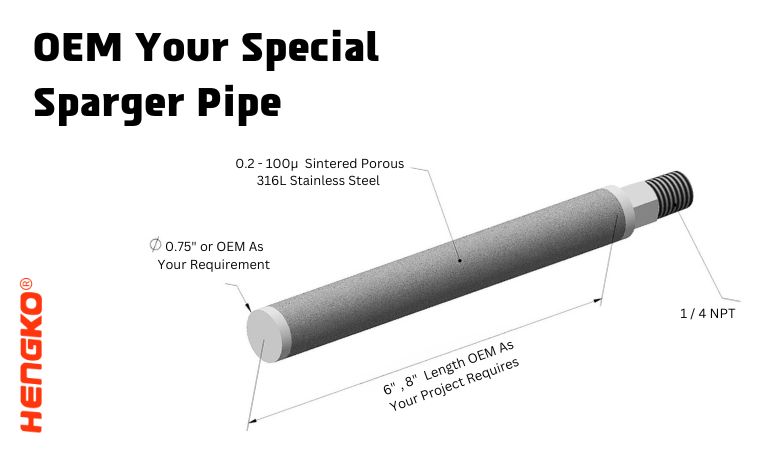

Cov yam ntxwv tseem ceeb ntawm Sparger Pipe

Lub sparger yeeb nkab yog ib hom yeeb nkab siv nyob rau hauv ntau yam kev lag luam kev siv, tshwj xeeb tshaj yog nyob rau hauv cov tshuaj thiab petrochemical industries.

Nws yog qhov tseem ceeb siv rau kev txhaj tshuaj roj rau hauv cov kua, feem ntau los pab txhawb kev siv tshuaj lom neeg lossis lwm yam kev xav tau.

Raws li hauv qab no yog qee yam ntawm cov yam ntxwv ntawm lub raj sparger, thov xyuas nws.

1. Khoom siv:

Sparger kav feem ntau yog tsim los ntawmstainless hlaulos yog lwm yamcorrosion-resistantcov ntaub ntawv.

Qhov no yog qhov tseem ceeb vim tias lawv feem ntau siv nrog cov tshuaj aggressively thiab yuav tsum tiv taus kev ua haujlwm hnyav.

2. Tsim:

Kev tsim cov yeeb nkab sparge yog qhov tseem ceeb rau nws txoj kev ua tau zoo.

Nws feem ntau suav nrog cov qhov me me los yog perforations raws li qhov ntev ntawm cov yeeb nkab kom tso pa tawm thiab tawg mus rau hauv cov kua.

Qhov sib nrug thiab qhov loj ntawm lub qhov tuaj yeem raug kho raws li cov txheej txheem tshwj xeeb.

3. Loj:

Qhov luaj li cas ntawm cov yeeb nkab sparger tuaj yeem sib txawv nyob ntawm daim ntawv thov, tab sis lawv feem ntau me me ntawm txoj kab uas hla dua lwm hom kav dej siv hauv tib txoj kev.

Qhov no yog vim hais tias cov roj txhaj los ntawm lub raj sparger yuav tsum tau ua kom zoo sib cais rau hauv cov kua kom tau txais txiaj ntsig zoo.

4. Kev sib txuas:

Cov kav dej Sparger tuaj yeem txuas nrog ntau yam khoom siv thiab cov kav dej.

Lawv yuav raug threaded, welded, los yog txuas nrog flanges, nyob ntawm seb qhov yuav tsum tau ua ntawm cov txheej txheem.

5. Kev ntxuav:

Vim tias cov kav dej sparger tau siv rau hauv cov txheej txheem uas muaj tshuaj lom neeg thiab lwm yam khoom siv, lawv yuav tsum tau ntxuav tsis tu ncua los tiv thaiv kev tsim thiab xeb.

Lawv tuaj yeem raug ntxuav nrog cov cuab yeej siv tshuab, xws li txhuam los yog blasting, lossis nrog cov tshuaj tov tshuaj.

Zuag qhia tag nrho, sparger tubes ua lub luag haujlwm tseem ceeb hauv ntau cov txheej txheem kev lag luam, thiab lawv cov qauv tsim thiab kev tsim kho yuav tsum yog

ua tib zoo tailored rau txhua daim ntawv thov tshwj xeeb los xyuas kom meej kev ua tau zoo thiab efficiency.

Sparger Pipe Classify

Sintered hlau sparger kav yuav raug cais raws li ntau yam qauv. Nov yog qee qhov kev faib ua feem:

-

Raws li Hom Gas Taw Qhia:

- Oxygen

- Nitrogen

- Cov pa roj carbon dioxide

- Argon

- Lwm yamgas sparger kav

-

Raws li Cov Duab los yog Tsim:

- Ncaj tsim

- U-shaped cev

- Coiled tube

- Lwm cov yeeb nkab zoo li

-

Raws li Porosity:

- Tsawg porosity sparger tube (tsawg dua 30%)

- Medium porosity yeeb nkab (30-50%)

- High porosity sparge yeeb nkab (ntau tshaj 50%)

-

Raws li Daim Ntawv Thov:

- Kev kho dej khib nyiab sparger yeeb nkab

- Fermentation sparger tube

- Chemical processing sparge yeeb nkab

- Pharmaceutical ntau lawm sparger yeeb nkab

- Lwm yam industrial sparger system

-

Raws li cov khoom siv:

- Stainless hlau sparger yeeb nkab

- Hastelloy sparger tube

- Inconel sparge yeeb nkab

- Lwm yam alloy sparger kav

Nco ntsoov tias cov kev faib tawm no tsis yog tag nrho thiab lwm cov txheej txheem kuj tuaj yeem siv los faib cov sintered hlau sparger kav.

Daim ntawv thov

Sintered hlau sparger kav muaj ntau yam kev siv hauv ntau yam lag luam, suav nrog:

1. Kev kho dej khib nyiab:

2. Fermentation:

3. Kev ua tshuaj lom neeg:

4. Pharmaceutical Production:

5. Kev tsim khoom noj thiab dej haus:

6. Kev saib xyuas ib puag ncig:

7. Petroleum thiab Gas Production:

8. Hlau Refining:

FAQ rau Sparger Pipe

1. Dab tsi yog Sparger Pipe?

Nyob rau hauv luv luv, Ib tug Sparger yeeb nkab yog ib tug ntxeem tau hlau yeeb nkab uas yog siv los qhia gases rau hauv cov kua rau ntau yam kev siv.Cov yeeb nkab feem ntau yog tsim los ntawm sintered Porous stainless hlau los yog lwm yam hlau zoo li alloys, thiab nta ib tug heev ntxeem tau qauv uas tso cai rau gases kom diffuse tusyees rau hauv cov kua. thiab tseem tuaj yeem yooj yim rau OEM qhov pore loj ntawm cov hlau, kom ua tau raws li qhov xav tau ntawm qhov system.

2. Dab tsi yog qee qhov kev siv ntawm sparger raj?

Cov kav dej Sparger feem ntau yog siv rau hauv kev siv xws li kev kho dej khib nyiab, fermentation, tshuaj ua haujlwm, thiab kev tsim tshuaj. Lawv tuaj yeem siv los qhia cov pa oxygen lossis lwm cov pa roj rau hauv cov kua dej, thiab tseem tuaj yeem siv rau kev sib xyaw thiab dispersion.

3. Dab tsi ntawm cov pa roj tuaj yeem qhia tau siv cov sintered hlau sparge yeeb nkab?

Lub sintered hlau sparge yeeb nkab yog ib qho cuab yeej siv los qhia cov pa roj rau hauv cov kua lossis cov khoom siv. Nws yog tsim los ntawm cov khoom hlau uas tau sib xyaw ua ke, tsim kom muaj cov qauv ntxeem tau uas tso cai rau cov roj ntws los ntawm nws. Qhov no tuaj yeem siv rau ntau yam kev siv xws li hauv brewing, tshuaj, tshuaj, thiab kev kho dej khib nyiab. Nov yog qee hom roj av uas tuaj yeem qhia tau siv lub sintered hlau sparge yeeb nkab:

1. Cua:Feem ntau siv rau hauv cov txheej txheem aeration los txhawb kev ua haujlwm lom neeg lossis sib tov tshuaj.

2. Cov pa oxygen:Siv rau hauv cov txheej txheem kev kho mob lom neeg, fermentation, thiab lwm yam kev siv uas yuav tsum tau muaj oxygen ntau ntxiv.

3. Cov pa roj carbon dioxide:Feem ntau siv hauv kev lag luam dej haus rau carbonation, nrog rau kev tswj pH hauv ntau cov txheej txheem tshuaj.

4. Nitrogen:Siv rau hauv cov ntawv thov uas yuav tsum muaj qhov cua inert, xws li hauv kev khaws cov zaub mov lossis hauv qee cov tshuaj tiv thaiv.

5. Hydrogen:Nws tuaj yeem siv rau hauv cov txheej txheem hydrogenation hauv kev lag luam tshuaj.

6. Chav:Txawm hais tias tsis yog ib qho roj hauv nws tus kheej, chav tuaj yeem qhia tau los ntawm sintered hlau sparge kav rau cua sov lossis lwm yam kev xav tau.

7. Cov tshuaj chlorine:Siv rau hauv cov txheej txheem kho dej rau kev tua kab mob.

8. Argon:Lwm cov roj inert, siv rau hauv daim ntawv thov qhov twg cov tshuaj tiv thaiv nrog cov ntaub ntawv nyob ib puag ncig yuav tsum raug txo kom tsawg.

9. Helium:Siv rau hauv kev tshawb nrhiav pom thiab lwm yam kev siv tshwj xeeb.

10. Tshwj xeeb Gases:Ntau lwm yam gases haum rau cov kev xav tau tshwj xeeb kuj tuaj yeem qhia los ntawm sintered hlau sparge kav, nyob ntawm qhov sib haum nrog cov ntaub ntawv thiab cov kev cai tshwj xeeb ntawm cov txheej txheem.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov sib xyaw ua ke ntawm cov roj nrog cov khoom siv ntawm sintered hlau sparge yeeb nkab yuav tsum raug txiav txim siab, vim qee cov pa roj tuaj yeem cuam tshuam nrog qee cov hlau. Tus tsim, nrog rau qhov pore loj thiab kev faib tawm, kuj yuav tsum tsim nyog rau cov roj tshwj xeeb thiab daim ntawv thov kom muaj kev faib tawm zoo thiab tiv thaiv kev txhaws lossis lwm yam teeb meem kev ua haujlwm.

4. Dab tsi yog qhov porosity ntawm ib txwm sintered hlau sparger yeeb nkab?

Lub porosity ntawm sintered hlau sparger yeeb nkab tuaj yeem sib txawv nyob ntawm cov ntawv thov tshwj xeeb thiab cov kev xav tau ntawm tus neeg siv. Feem ntau, porosities muaj li ntawm 20 mus rau 60% los ntawm ntim.

5. Lub Sparger Pipe ua li cas?

Sintered hlau sparger raj yog tsim los ntawm kev siv cov txheej txheem hu ua hmoov metallurgy, uas koom nrog nias hlau hmoov

mus rau hauv ib tug tshwj xeeb zoo thiab ces cua sov nws mus rau ib tug kub kub los tsim ib tug khoom, ntxeem tau qauv.

Cov yeeb nkab sparger yog ib qho cuab yeej siv los qhia cov pa roj rau hauv cov kua dej, feem ntau siv hauv kev lag luam xws li fermentation, chemical processing, lossis kev kho dej khib nyiab. Cov txheej txheem tsim khoom rau cov yeeb nkab sparger tuaj yeem sib txawv nyob ntawm qhov kev tsim tshwj xeeb thiab daim ntawv thov, tab sis ntawm no yog cov ntsiab lus dav dav ntawm yuav ua li cas cov yeeb nkab sparger yuav ua tau:

1. Kev xaiv cov khoom siv:Cov khoom siv yuav tsum raug xaiv raws li daim ntawv thov thiab hom roj thiab kua cuam tshuam. Cov ntaub ntawv muaj xws li stainless hlau, titanium, los yog tshwj xeeb alloys uas tiv thaiv corrosion.

2. Tsim thiab Kev Npaj:Kev tsim ntawm cov yeeb nkab sparger yuav nyob ntawm qhov kev thov tshwj xeeb. Nws tuaj yeem suav nrog ntau lub qhov me me lossis lub nozzles kom ntseeg tau tias txawm tias faib cov pa roj. Tus tsim feem ntau ua tiav siv CAD (Computer-Aided Design) software.

3. Txiav thiab Shaping:Cov khoom uas tau xaiv yog txiav thiab ua rau hauv daim ntawv xav tau. Qhov no yuav koom nrog cov txheej txheem xws li laser txiav, txiav ntshav plasma, lossis dej dav hlau txiav los tsim lub cev tseem ceeb ntawm cov yeeb nkab.

4. Drilling lossis Punching Qhov:Cov qhov me me los yog lub nozzles yog tsim nyob rau hauv cov yeeb nkab kom cia cov roj khiav mus rau hauv cov kua. Qhov no tuaj yeem ua tiav los ntawm kev drilling, xuas nrig ntaus, lossis lwm yam txheej txheem tshwj xeeb.

5. Vuam thiab sib dhos:Yog tias cov yeeb nkab sparger muaj ntau qhov chaw, lawv tau sib sau ua ke thiab welded ua ke. Qhov no yuav suav nrog txuas flanges, fittings, lossis lwm yam khoom.

6. Kev kho deg:Nyob ntawm daim ntawv thov, qhov saum npoo ntawm cov yeeb nkab sparger yuav raug kho los txhim kho nws cov khoom. Qhov no tuaj yeem suav nrog polishing los tsim ib qho chaw du lossis siv cov txheej txheem los ua kom muaj kev tiv thaiv corrosion.

7. Kev Ntsuas thiab Kev Tswj Xyuas Zoo:Cov yeeb nkab tiav sparger raug sim los xyuas kom meej tias nws ua tau raws li qhov yuav tsum tau ua. Qhov no tuaj yeem suav nrog kev ntsuas siab, ntsuas qhov xau, thiab tshuaj xyuas qhov tsis xws luag.

8. Ntim thiab Shipping:Thaum cov yeeb nkab sparger tau dhau tag nrho cov kev tswj xyuas zoo, nws tau ntim thiab npaj rau kev xa mus rau cov neeg siv khoom.

9. Kev teeb tsa:Nyob ntawm qhov nyuaj, cov yeeb nkab sparger yuav xav tau kev teeb tsa kev tshaj lij. Qhov no tuaj yeem koom nrog kev sib koom ua ke rau hauv cov kav dej uas twb muaj lawm, ua kom muaj kev sib raug zoo, thiab ua kom muaj kev sib txuas tsim nyog.

10. Kev tu thiab saib xyuas:Kev saib xyuas tsis tu ncua thiab kev saib xyuas yuav tsum tau ua kom ntseeg tau tias cov yeeb nkab sparger tseem ua haujlwm zoo. Qhov no tuaj yeem suav nrog kev tu tsis tu ncua, tshuaj xyuas, thiab hloov cov khoom hnav.

Cov txheej txheem tseeb tuaj yeem sib txawv nyob ntawm qhov tsim tshwj xeeb ntawm cov yeeb nkab sparger thiab cov kev xav tau ntawm daim ntawv thov. Kev cai sparger kav tej zaum yuav xav tau cov txheej txheem tsim tshwj xeeb thiab cov kauj ruam ntxiv kom tau raws li qhov tshwj xeeb.

6. Qhov siab tshaj plaws ua haujlwm kub ntawm Sparger Tube yog dab tsi?

Qhov siab tshaj plaws kev khiav hauj lwm kub ntawm ib tug sintered hlau sparger raj yog nyob ntawm cov tshwj xeeb alloy siv los tsim cov yeeb nkab. Feem ntau, lawv tuaj yeem ua haujlwm ntawm qhov kub txog li 800 ° C (1472 ° F).

7. Qhov siab tshaj plaws kev khiav hauj lwm siab ntawm sintered hlau sparger yeeb nkab yog dab tsi?

Qhov siab tshaj plaws kev khiav hauj lwm siab ntawm ib tug sparger yeeb nkab nyob ntawm seb tus tsim tshwj xeeb ntawm cov yeeb nkab thiab cov ntaub ntawv siv. Feem ntau, lawv tuaj yeem ua haujlwm ntawm qhov siab txog 10 bar (145 psi).

8. Lub sintered hlau sparger raj feem ntau kav ntev npaum li cas?

Lub neej ntev ntawm sintered hlau sparger yeeb nkab nyob ntawm cov ntawv thov tshwj xeeb thiab cov xwm txheej uas nws siv. Raws li kev ua haujlwm ib txwm muaj, lawv tuaj yeem kav ntev li ob peb xyoos.

9. Cov kav dej sintered hlau puas tuaj yeem ntxuav tau?

Yog lawm, sintered hlau sparger tube tuaj yeem ntxuav tau siv ntau txoj hauv kev, suav nrog kev rov qab ntxuav, ntxuav ultrasonic, thiab tshuaj ntxuav.

10. Cov sintered hlau sparger raj puas tuaj yeem ua kom tsis muaj menyuam?

Yog lawm, sintered hlau sparge kav yuav sterilized siv ntau txoj kev, nrog rau autoclaving, gamma irradiation, thiab tshuaj sterilization.

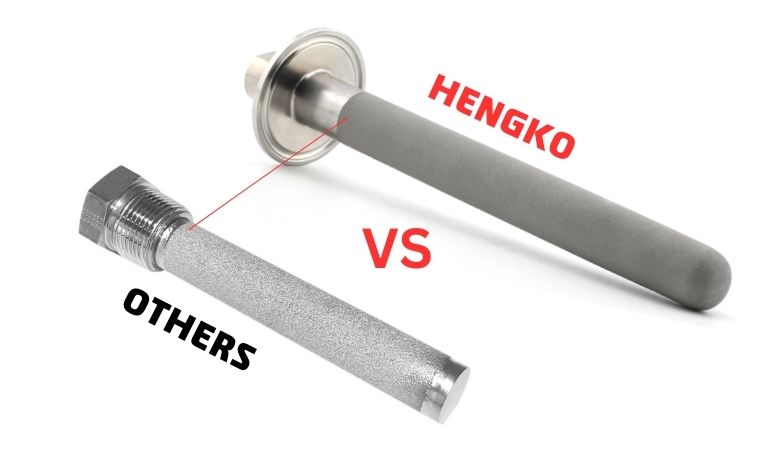

11. Dab tsi yog qhov zoo ntawm kev siv sintered stainless hlau sparger kav?

Sintered stainless hlau sparger kav yog dav siv nyob rau hauv ntau yam industries los qhia gases rau hauv cov kua los yog lwm yam ntaub ntawv. Lawv muab ntau yam zoo uas ua rau lawv haum rau ntau daim ntawv thov:

1. Durability:Stainless hlau yog lub npe hu rau nws tiv thaiv corrosion thiab hnav. Qhov no ua rau sintered stainless hlau sparger kav kav ntev thiab haum rau siv nrog ntau yam tshuaj thiab nyob rau hauv ib puag ncig sib txawv.

2. Uniform Gas Distribution:Cov qauv ntxeem tau ntawm sintered stainless hlau tso cai rau ib qho kev faib tawm ntawm cov roj. Qhov no tuaj yeem ua rau muaj txiaj ntsig zoo dua los yog cov tshuaj tiv thaiv, nyob ntawm daim ntawv thov.

3. Kub Resistance:Stainless hlau tuaj yeem tiv taus qhov kub thiab txias, ua rau cov kav dej sparger haum rau cov txheej txheem uas yuav tsum tau ua kom sov lossis ua rau qhov kub siab.

4. Chemical Resistance:Stainless hlau yog resistant rau ntau yam tshuaj, ua rau cov sparger kav no haum rau siv nyob rau hauv ntau yam chemical txheej txheem yam tsis muaj kev pheej hmoo ntawm corrosion los yog lwm yam tshuaj tiv thaiv nrog cov khoom.

5. Customizable Pore Loj:Cov txheej txheem sintering tso cai rau kev tswj xyuas qhov pore loj thiab kev faib tawm hauv cov khoom. Qhov no txhais tau hais tias cov kav dej sparger tuaj yeem hloov kho kom haum rau cov ntawv thov tshwj xeeb, txawm tias yuav tsum muaj cov npuas zoo rau kev sib xyaw ua ke lossis cov npuas loj dua rau kev ua kom muaj zog ntxiv.

6. Yooj yim ntawm kev ntxuav:Lub npoo du ntawm cov hlau tsis huv ua rau nws yooj yim los ntxuav, uas yog qhov tseem ceeb tshwj xeeb hauv kev lag luam xws li kev ua zaub mov los yog cov tshuaj uas tu cev yog qhov tseem ceeb heev.

7. Siab Resistance:Sintered stainless hlau sparger kav dej tuaj yeem tiv taus kev kub ntxhov, ua rau lawv tsim nyog rau cov ntawv thov uas ua haujlwm nyob rau hauv siab ntau yam tsis muaj kev pheej hmoo ntawm kev ua tsis tiav.

8. Compatibility nrog ntau yam Gases:Raws li tau hais ua ntej, cov kav dej sparger no tuaj yeem siv nrog ntau cov pa roj carbon monoxide, los ntawm huab cua thiab oxygen mus rau cov roj tshwj xeeb lossis reactive gases.

9. Nqi-zoo:Txawm hais tias tus nqi pib yuav siab dua piv rau lwm cov ntaub ntawv, qhov kev ua haujlwm ntev thiab kev saib xyuas qis ntawm sintered stainless hlau tuaj yeem ua rau nws xaiv tus nqi zoo nyob rau lub sijhawm ntev.

10. Ib puag ncig phooj ywg:Stainless hlau yog recyclable, thiab ntev lifespan ntawm cov sparger kav no kuj pab txhawb rau lawv ib puag ncig sustainability.

11. Scalability:Sintered stainless hlau sparger kav yuav raug tsim nyob rau hauv ntau qhov ntau thiab tsawg thiab cov duab, ua rau lawv haum rau ob qho tib si kev sim me me thiab cov txheej txheem loj.

Nyob rau hauv cov ntsiab lus, sintered stainless hlau sparger kav muaj ib tug ua ke ntawm durability, efficiency, thiab versatility uas ua rau lawv haum rau ntau yam kev siv. Lawv tiv taus corrosion, muaj peev xwm tiv taus qhov kub thiab txias, thiab cov khoom siv kho kom haum ua rau lawv muaj koob meej hauv ntau yam lag luam.

12. Dab tsi yog qhov tsis zoo ntawm kev siv sintered hlau sparge kav?

Qee qhov tsis zoo ntawm kev siv sintered hlau sparger tubes suav nrog lawv cov nqi pib siab, muaj kev cuam tshuam rau clogging los yog fouling, thiab lub peev xwm rau corrosion yog tias tsis yog ua los ntawm cov hlau raug raug.

More questions about the sintered metal sparger pipes, you are welcome to contact us by email ka@hengko.com, we are pleasure to supply

koj daws qhov zoo tshaj plaws rau koj qhov project tshwj xeeb thiab daim ntawv thov.