Sintering plays lub luag haujlwm tseem ceeb hauv kev lag luam tsim khoom, ua kom muaj cov khoom sib txawv thiab ruaj khov.Kev nkag siab txog cov hauv paus ntsiab lus ntawm sintering yog qhov tseem ceeb rau cov engineers, cov kws tshawb fawb, thiab cov neeg nyiam sib xws.Kab lus no tsom mus rau delve rau hauv lub tswv yim ntawm sintering, tshawb xyuas nws cov txheej txheem, sib tham txog nws cov ntawv thov, thiab qhia txog nws qhov zoo thiab cov kev txwv.

Sintering yog dab tsi?

Sintering yog ib qho txheej txheem uas suav nrog kev cog cov hmoov nplej rau hauv cov khoom loj los ntawm kev siv cua sov.Tsis zoo li cov txheej txheem melting ib txwm, sintering tsis ncav cuag cov khoom siv melting point.Es tsis txhob, nws siv cov diffusion ntawm atoms thoob plaws cov khoom, uas ua rau kev sib txuas thiab densification.Cov txheej txheem no ua rau muaj cov qauv ruaj khov nrog kev txhim kho cov khoom siv kho tshuab.

Sintering kuj muaj qhov dav thiab nqaim.Rau kev nkag siab dav, sintering yog txheej txheem uas cov hmoov xoob tau sib sau ua ke los ntawm cov khoom sib txuas ntawm lub zog ntawm qee qhov kub.Tab sis sintering nyob rau hauv lub tshav pob ntawm hlau ua yog ib tug txheej txheem uas combines hlau ore hmoov thiab lwm yam ntaub ntawv uas muaj hlau mus rau hauv lub zoo heev metallurgical kev ua tau zoo dag block los ntawm fusion, nws ntau lawm yog sinter.Lawv koom nrog cov txheej txheem physicochemical sib txawv Txawm hais tias lawv ob leeg siv lo lus sintering.

Txoj Kev Sintering

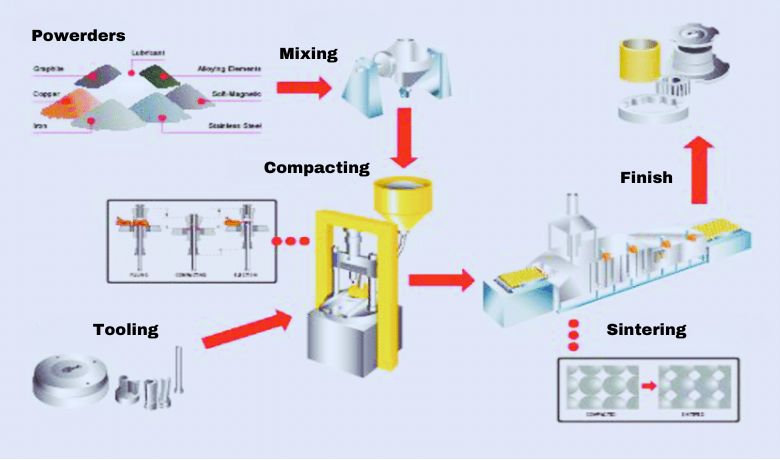

Cov txheej txheem sintering muaj ntau theem.Thaum xub thawj, cov khoom siv raw yog tsim rau hauv cov duab tshwj xeeb, feem ntau yog nyob rau hauv daim ntawv ntawm hmoov.Cov hmoov no yog ces compacted siv lub siab los xyuas kom meej uniformity thiab tshem tawm voids.Tom ntej no, cov khoom siv compacted raug tswj cua sov hauv lub qhov cub sintering.Qhov kub thiab txias yog ua tib zoo tswj kom yooj yim particle bonding tsis ua kom tiav melting.Thaum lub sij hawm cua sov, cov hais undergo diffusion, ua rau lub caj dab tsim thiab densification.Cov theem kawg yuav tsum ua kom txias cov khoom sintered, tso cai rau nws kom khov rau hauv cov qauv nruj thiab cohesive.

Cov hmoov sintering peb siv los hais yog cov hmoov hlau los yog hmoov compact.Nws yog cov txheej txheem khoom siv tes ua los ntawm kev tau txais cov khoom lossis cov khoom lag luam hauv qhov yuav tsum tau muaj zog thiab peculiarities vim lub cev thiab tshuaj lom neeg kev sib raug zoo ntawm cov khoom ntawm qhov kub thiab txias hauv qab lub melting point ntawm lub ntsiab tivthaiv.HENGKO muaj cov hmoov sintering khoom ntawm ntau yam specifications thiab ntau thiab tsawg suav nrogdisc lim, khob lim,tswm ciab lim,ntawv limthiab lwm yam.Peb cov khoom sintering stainless hlau muaj qhov zoo ntawm lub zog siab, zoo permeability, pom tseeb tseeb thiab corrosion kuj, haum rau ntau qhov chaw.Customized service kuj muab raws li koj thov.

Txhua kauj ruam hauv cov txheej txheem sintering yog kev sib cuam tshuam, thiab kev mloog zoo yog cov kauj ruam tseem ceeb hauv cov txheej txheem sintering, yog li ntawd qhov kev mloog zoo txhais li cas?Concentrateis cov kauj ruam uas ua kom zoo dua cov khoom siv raw thiab roj, ua rau nws dhau los ua lub nra ntawm lub cub tawg. cov kev xav tau ntawm kev ntxiv dag zog rau lub tshuab hluav taws xob refining ua ntej cov khoom siv raw thiab roj nkag mus rau hauv qhov cub tawg.Kev ntsuas kev lag luam thiab kev lag luam siab dua thiab cov txiaj ntsig kev lag luam tuaj yeem tau txais tom qab cov concentrateis siv hauv qhov cub tawg smelting.Dab tsi yog hu ua "ua kom zoo tshaj plaws siv txhua yam" thiab ua kom zoo tshaj plaws siv cov peev txheej.Nws kuj yog ib hom kev paub txog kev txuag thiab kev tiv thaiv ib puag ncig.

Cov yam ntxwv cuam tshuam rau Sintering

Ntau yam cuam tshuam rau cov txheej txheem sintering, suav nrog qhov kub thiab txias, cua sov tus nqi, siab, particle loj, thiab muaj pes tsawg leeg.Kub ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab sintering kinetics thiab cov khoom tsim tawm.Cov cua kub cuam tshuam rau cov txheej txheem densification, raws li cua sov sai yuav ua rau tsis sib xws rau qhov sib txuam tsis sib xws.Lub siab yog siv thaum lub sij hawm compaction los txhim kho particle rearrangement thiab tshem tawm porosity.Particle loj thiab muaj pes tsawg leeg cuam tshuam tus cwj pwm sintering, nrog me me hais thiab homogeneous compositions txhawb kom zoo densification.

Los ntawm cov lus pom ntawm lo lus sintering, lo lus hlawv yog siv hluav taws, yuav tsum muaj nplaim taws nrog rau qhov kub thiab txias.Thiab cov txheej txheem ntawm sintering yuav tsum tau ua nyob rau hauv high kub.Qhov kub thiab txias yog tsim los ntawm kev hlawv roj.Qhov kub thiab txias, qhov kub ceev, qhov dav ntawm qhov kub hnyiab, qhov cua hauv cov khoom siv sintered, thiab lwm yam yuav cuam tshuam rau kev nce qib ntawm cov txheej txheem sintering thiab qhov zoo ntawm cov khoom sintered kawg.Thiab cov ntsiab lus no muaj feem xyuam rau lub cev thiab tshuaj lom neeg ntawm cov roj thiab ntau npaum li cas.Yog li ntawd, lub cev thiab tshuaj lom neeg cov khoom ntawm cov roj yog ib qho tseem ceeb ntawm cov txheej txheem sintering.

Metaphor ib yam dab tsi yuav tsis muaj nyob tsis muaj lub hauv paus ntawm lawv nyob.Roj thiab cov khoom siv raw zoo ib yam li daim tawv nqaij thiab ntoo uas muaj kev sib raug zoo yog qhov tseem ceeb.Yog tsis muaj ib qho, Cov txheej txheem sintering tsis tuaj yeem coj qhov chaw.Tab sis Sintered roj feem ntau yog hais txog cov khoom siv roj hlawv hauv cov khoom txheej.Feem ntau siv yog pulverized coke hmoov thiab anthracite, thiab lwm yam sintered raw cov ntaub ntawv, feem ntau muaj cov hlau ore, manganese ore, hnyav, roj thiab cov khoom pov tseg.

Ntau hom Sintering

Sintering encompasses ntau yam txuj ci uas tau muab cais raws li cov txheej txheem thiab cov xwm txheej koom nrog hauv cov txheej txheem.Nkag siab txog ntau hom sintering yog qhov tseem ceeb rau kev xaiv txoj kev tsim nyog rau cov ntawv thov tshwj xeeb.Nov yog qee hom kev sintering:

1 Solid-State Sintering

Solid-state sintering, tseem hu ua diffusion bonding, yog ib txoj kev siv dav siv sintering.Hauv cov txheej txheem no, cov ntaub ntawv hmoov yog raug rau qhov kub siab tshaj hauv qab lawv cov ntsiab lus melting.Raws li qhov kub thiab txias, atomic diffusion tshwm sim ntawm cov khoom uas nyob ib sab, ua kom yooj yim rau kev tsim ntawm caj dab thiab kev sib txuas.Kev tshem tawm cov voids thiab rov kho cov khoom ua rau densification thiab tsim cov khoom loj.

Lub xeev sintering feem ntau yog siv rau hauv kev tsim cov ceramics, xws li cov plooj (porcelain) thiab alumina, nrog rau kev sintering ntawm cov hmoov hlau.Nws yog txaus siab thaum khaws cia cov tshuaj muaj pes tsawg leeg thiab purity ntawm cov khoom yog qhov tseem ceeb.Los ntawm ua tib zoo tswj cov sintering tsis, xws li kub, lub sij hawm, thiab siab, cov khoom uas xav tau yuav ua tiav.

2 Liquid-Phase Sintering

Ua kua-theem sintering muaj qhov sib ntxiv ntawm cov theem ua kua los pab hauv kev hloov pauv thiab kev sib koom ua ke thaum lub sijhawm sintering.Cov theem ua kua, feem ntau yog cov khoom siv qis-melting-point, ua raws li cov ntaub ntawv los yog cov dej ntws, txo cov sintering kub uas yuav tsum tau ua kom densification.Txoj kev no yog qhov tshwj xeeb tshaj yog thaum sintering cov ntaub ntawv uas muaj cov ntsiab lus melting siab lossis thaum txhim kho qhov densification tus nqi xav tau.

Thaum lub sij hawm ua kua-theem sintering, cov kua theem kis ntawm cov hais, txhawb particle rearrangement thiab txhim kho lub caj dab tsim thiab densification.Lub xub ntiag ntawm cov kua theem kuj ua rau kom tshem tawm impurities thiab yooj yim rau sintering ntawm cov ntaub ntawv nrog complex compositions.

Cov kua-theem sintering feem ntau yog siv rau hauv kev tsim cov cemented carbide, qhov twg tungsten carbide hais yog sib koom nrog siv cobalt-raws li binder.Nws kuj tseem ua haujlwm nyob rau hauv sintering ntawm tej yam ceramics thiab hlau alloys, xws li stainless hlau.

3 Qhib Sintering

Activated sintering, tseem hu ua field-pab sintering lossis spark plasma sintering, yog cov txheej txheem sintering tshiab uas siv cov khoom siv hluav taws xob sab nraud los txhawb kev ntom ntom.Nws suav nrog kev siv hluav taws xob, hluav taws xob tam sim no, lossis hluav taws xob hluav taws xob los txhim kho cov txheej txheem sintering.

Lub zog sab nraud ua kom nrawm nrawm ntawm atomic diffusion, ua rau lub caj dab sai sai thiab densification.Daim ntawv thov ntawm hluav taws xob hluav taws xob tsim hluav taws xob hauv cheeb tsam, txo lub sij hawm sintering thiab ua kom cov sintering ntawm cov ntaub ntawv ntawm qhov kub thiab txias.Cov txheej txheem no muaj cov txiaj ntsig zoo li txhim kho densification, cov roj cog qoob loo, thiab txhim kho kev tswj hwm microstructure thiab cov khoom.

Activated sintering pom cov ntawv thov hauv ntau qhov chaw, suav nrog kev tsim cov ceramics siab heev, cov ntaub ntawv ua haujlwm, thiab cov khoom sib xyaw.Nws yog tshwj xeeb tshaj yog zoo rau cov ntaub ntawv uas siab melting ntsiab lus, complex compositions, los yog tsawg sinterability.

4 Lwm Hom Sintering

Sib nrug los ntawm cov lus hais saum toj no, muaj ob peb lwm txoj kev tshwj xeeb sintering raws li cov ntawv thov tshwj xeeb.Cov no suav nrog microwave sintering, qhov twg lub zog microwave yog siv los ua kom sov thiab sinter cov khoom, thiab lub siab-pab sintering, uas sib txuas lub siab thiab cua sov los txhim kho qhov ntom ntom.

Tsis tas li ntawd, xaiv laser sintering (SLS) thiab electron beam sintering (EBS) yog cov txheej txheem tsim khoom ntxiv uas siv cov kab hluav taws xob los xaiv sinter hmoov cov ntaub ntawv, txheej los ntawm txheej, los tsim cov khoom peb-dimensional complex.

Txhua hom sintering muaj qhov tshwj xeeb zoo thiab raug xaiv raws li cov khoom siv, cov txiaj ntsig xav tau, thiab cov ntawv thov tshwj xeeb.

Kev siv ntawm Sintering

Sintering pom ntau daim ntawv thov thoob plaws ntau yam kev lag luam vim nws lub peev xwm los hloov cov hmoov hmoov rau hauv cov khoom siv nrog cov khoom zoo dua qub.Cia peb tshawb txog qee qhov chaw tseem ceeb uas sintering yog dav siv:

1 - Ceramics

Ceramics yog ib qho ntawm cov teb tseem ceeb uas sintering feem ntau siv.Sintered ceramics nthuav tawm txhim kho txhua yam zog, hardness, thiab thermal stability.Sintering yog ua haujlwm nyob rau hauv kev tsim cov vuas luaj ceramic, cov khoom huv huv, cov cuab yeej txiav, cov ntaub ntawv refractory, thiab hluav taws xob insulators.Los ntawm kev ua tib zoo tswj cov sintering tsis, cov ntaub ntawv ceramic tuaj yeem ua tiav qhov xav tau ceev, porosity, thiab microstructure rau cov ntawv thov tshwj xeeb.

2 - Metallurgy

Hauv kev siv metallurgical, sintering yog siv los tsim ntau yam khoom siv hlau.Qhov no suav nrog cov iav, bearings, bushings, automotive qhov chaw, thiab cov khoom siv.Cov hmoov hlau, xws li hlau, txhuas, thiab stainless hlau, yog compacted thiab sintered los tsim cov khoom siv nrog cov khoom zoo heev.Sintered hlau Cheebtsam feem ntau pom muaj zog dua, hnav tsis kam, thiab qhov tseeb qhov tseeb piv rau cov tsoos cam khwb cia.

3 - Composites

Sintering plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom sib xyaw, qhov twg ob lossis ntau qhov sib txawv ntawm cov khoom sib xyaw ua ke los tsim cov ntaub ntawv nrog cov khoom zoo.Nyob rau hauv kev tsim cov hlau matrix composites (MMCs) thiab ceramic matrix composites (CMCs), sintering yog ua hauj lwm los khi cov ntaub ntawv ntxiv, xws li fibers los yog hais, nrog rau cov khoom matrix.Qhov no txhim khu lub zog, nruj, thiab toughness ntawm cov khoom sib xyaw ua ke.

4 - Hmoov Metallurgy

Hmoov metallurgy, ib ceg tshwj xeeb ntawm metallurgy, feem ntau tso siab rau sintering.Nws koom nrog kev tsim cov khoom siv hlau los ntawm cov hmoov hlau.Los ntawm cov txheej txheem zoo li compaction thiab sintering, intricate qhov chaw nrog cov duab nyuaj tuaj yeem tsim.Hmoov metallurgy feem ntau yog siv rau hauv kev lag luam tsheb rau kev tsim cov iav, camshafts, thiab lub rooj zaum valve, nrog rau kev tsim cov cuab yeej txiav thiab sintered lim.

5 - 3D Printing / Additive Manufacturing

Sintering plays lub luag haujlwm tseem ceeb hauv kev tsim khoom ntxiv xws li xaiv laser sintering (SLS) thiab electron beam sintering (EBS).Nyob rau hauv cov txheej txheem no, cov ntaub ntawv hmoov yog xaiv sintered txheej los ntawm txheej, raws li cov qauv tsim, los tsim cov khoom peb-dimensional complex.Sintering tso cai rau kev sib sau ua ke thiab kev sib koom tes ntawm cov hmoov cov hmoov, ua rau muaj ntom ntom ntom ntom thiab ua haujlwm.Cov thev naus laus zis no tau siv ntau yam kev lag luam, suav nrog aerospace, kev kho mob, thiab kev tsim qauv.

6 Electronics thiab Hluav Taws Xob Engineering

Sintering yog ua haujlwm hauv kev tsim cov khoom siv hluav taws xob thiab hluav taws xob.Hauv kev tsim hluav taws xob ceramics, xws li capacitors, varistors, thiab thermistor, sintering yog siv los khi cov khoom siv ceramic, tsim cov khoom ntom ntom thiab cov khoom siv hluav taws xob.Sintering kuj tseem siv rau hauv kev tsim hluav taws xob tiv tauj, ntim khoom semiconductor, thiab cov khoom siv hluav taws xob.

Cov no tsuas yog qee qhov piv txwv ntawm ntau hom kev siv sintering.Cov txheej txheem tseem tab tom tshawb nrhiav thiab ua kom zoo dua qub kom tau raws li qhov xav tau ntawm cov kev lag luam sib txawv, ua rau kev tsim cov khoom siv thiab cov khoom siv tau zoo.

Qhov zoo ntawm Sintering

Sintering muaj ntau yam zoo uas ua rau nws nyiam kev tsim khoom hauv ntau qhov kev lag luam.Cia peb tshawb txog qee qhov txiaj ntsig tseem ceeb:

1 Complex Shapes thiab Intricate Designs

Ib qho txiaj ntsig tseem ceeb ntawm sintering yog nws lub peev xwm los tsim cov khoom nrog cov duab nyuaj thiab cov qauv tsim sib txawv.Los ntawm kev siv cov khoom siv hmoov, sintering tso cai rau kev tsim cov khoom nrog cov geometries intricate uas yuav nyuaj kom ua tiav siv cov txheej txheem machining ib txwm.Qhov kev hloov pauv no ua rau kev tsim cov khoom tsim kho kom haum rau cov kev siv tshwj xeeb.

2 Txhim kho Mechanical Properties

Sintering txhim kho cov khoom siv ntawm cov khoom siv, ua rau cov khoom siv nrog cov yam ntxwv zoo dua.Thaum lub sij hawm sintering txheej txheem, cov khoom sib txuas thiab densify, ua rau txhim kho lub zog, hardness, thiab hnav tsis kam ntawm cov khoom sintered.Cov khoom siv cua sov thiab kev sib txawv cuam tshuam nrog hauv Sintering pab txhawb rau kev txhim kho cov qauv ntom thiab kev txhim kho tag nrho cov tshuab sib luag ntawm cov khoom siv.

3 Cov khoom sib xyaw ua ke

Sintering tso cai rau kev sib sau ua ke ntawm cov hmoov sib txawv nrog cov khoom sib txawv, ua kom cov khoom tsim nrog cov khoom zoo.Los ntawm kev sib xyaw ntau hom hmoov los yog sib xyaw cov khoom ntxiv, nws tuaj yeem hloov kho cov khoom siv raws li cov kev xav tau tshwj xeeb.Qhov yooj yim hauv kev sib xyaw no qhib qhov muaj peev xwm los tsim cov khoom siv qib siab nrog kev ua haujlwm zoo, xws li cov khoom siv muaj zog siab lossis cov khoom siv nrog cov khoom siv hluav taws xob lossis thermal.

4 Tus nqi-zoo

Sintering yog ib txoj kev tsim khoom raug nqi piv rau cov txheej txheem melting thiab casting.Kev siv cov hmoov nplej txo cov khoom pov tseg, vim tias cov hmoov nplej ntau dhau tuaj yeem khaws thiab rov siv dua.Tsis tas li ntawd, cov txheej txheem sintering yuav tsum tau siv lub zog qis dua vim tias nws ua haujlwm ntawm qhov kub thiab txias hauv qab lub melting point ntawm cov khoom.Lub peev xwm los tsim cov khoom ze-net-puab txuas ntxiv txo qhov kev xav tau ntawm kev ua haujlwm tom qab machining, ua rau kev txuag nqi ntawm cov khoom siv, kev siv hluav taws xob, thiab kev ua haujlwm tom qab.

5 Versatility hauv kev xaiv cov khoom

Sintering muaj ntau yam hauv kev xaiv cov khoom, haum rau ntau yam khoom siv rau ntau yam kev siv.Nws yog tsim rau ceramics, hlau, thiab composites.Cov khoom sib txawv, suav nrog oxides, carbides, nitrides, thiab alloys, tuaj yeem ua tiav los ntawm sintering.Qhov kev sib raug zoo ntawm cov khoom siv dav no tso cai rau kev tsim cov khoom sib txawv nrog cov khoom siv tshwj xeeb, ua rau sintering ib qho kev xaiv txaus nyiam rau ntau yam lag luam.

Sintering qhov zoo ntawm txoj kev shaping, txhim kho cov khoom siv kho tshuab, cov khoom sib xyaw ua ke, kev ua tau zoo, thiab cov khoom siv ntau yam ua rau nws muaj txiaj ntsig tsim khoom hauv ntau qhov chaw.Los ntawm kev siv cov txiaj ntsig no, kev lag luam tuaj yeem ua tiav ntau lawm, txhim kho kev ua tau zoo, thiab txuag nqi hauv lawv cov txheej txheem tsim khoom.

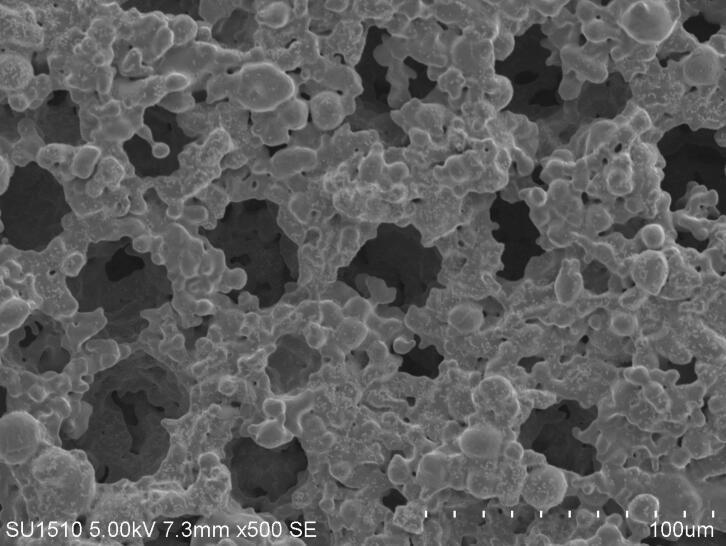

Muaj ntau qhov kev hloov pauv nrog rau kev hloov pauv ntawm lub cev thiab tshuaj lom neeg.Kev siv lub cev thiab tshuaj lom neeg hauv cov hmoov sintering nrog rau cov evaporation los yog evaporation ntawm cov dej los yog cov organic teeb meem, tshem tawm cov adsorbed gases, kev nyuaj siab, txo cov nto oxides ntawm hmoov hais, cov khoom tsiv teb tsaws, recrystallization, grain loj hlob, thiab lwm yam Nws yog ib qho tseem ceeb heev uas yuav tsum tau kawm. thiab nkag siab txog kev paub sintering raws li tus neeg tsim khoom.Thiab raws li cov neeg siv khoom, kev kawm cov kev paub yooj yim no tuaj yeem ua rau peb muaj lub tswv yim zoo thaum xaiv cov khoom siv sintering.

Sintering yog ib txwm ua thiab complex txheej txheem.Lub sij hawm yog nce mus, Thiab ntau lawm technology thiab cov khoom siv ntau lawm kuj hloov kho tas li.Khaws cov kev paub yooj yim thiab kawm cov kev paub tshiab yog tsim nyog rau cov neeg ua haujlwm hauv kev lag luam.Rau 18 xyoo dhau los.HENGKOib txwm hais kom txhim kho nws tus kheej tas li, muab cov neeg siv khoom nrog cov khoom zoo thiab cov kev pabcuam zoo, pab cov neeg siv khoom thiab kev txhim kho.Peb cia siab tias yuav dhau los ua koj tus khub ntev ntev.

FAQs (Cov lus nug nquag nug)

Cov ntaub ntawv dab tsi tuaj yeem sintered?

Ntau yam khoom siv tuaj yeem ua sintered, suav nrog ceramics, hlau, thiab cov khoom sib xyaw.Piv txwv muaj xws li ceramic hmoov zoo li alumina thiab zirconia, hlau hmoov zoo li hlau thiabsintered stainless hlau lim, thiab cov hmoov sib xyaw uas muaj cov khoom siv ntxiv xws li fibers lossis cov khoom.

Dab tsi yog qhov zoo ntawm sintering piv rau lwm txoj kev tsim khoom?

Sintering muaj ntau yam zoo dua li cov txheej txheem tsim khoom.Nws tso cai rau kev tsim cov khoom siv nrog cov duab sib txawv thiab cov qauv tsim sib txawv, muaj cov khoom siv kho kom zoo dua qub, ua kom muaj kev sib haum xeeb ntawm cov khoom sib xyaw, yog tus nqi zoo vim txo cov khoom pov tseg, thiab haum rau ntau yam khoom siv rau kev siv sib txawv.

Dab tsi yog cov ntawv thov tseem ceeb ntawm sintering?

Sintering pom cov ntawv thov hauv kev lag luam xws li ceramics, metallurgy, hmoov metallurgy, electronics, thiab additive manufacturing.Nws yog siv los tsim cov vuas luaj ceramic, cov khoom siv hauv tsheb, cov khoom siv hlau, cov cuab yeej txiav, hluav taws xob ceramics, thiab cov khoom 3D luam tawm, thiab lwm yam.

Puas muaj kev txwv lossis kev sib tw nrog sintering?

Sintering muaj qee qhov kev txwv thiab cov nyom.Kev ua kom zoo sib xws thoob plaws hauv cov khoom tuaj yeem yog ib qho kev sib tw, vim tias cua sov tsis sib xws los yog kev faib tawm tuaj yeem ua rau muaj qhov tsis xws luag.Kev tswj cov qoob loo loj hlob thiab tiv thaiv kev poob qis thaum lub sij hawm sintering kuj tseem ceeb heev.Tsis tas li ntawd, tsis yog tag nrho cov ntaub ntawv tsim nyog rau sintering vim lawv cov ntsiab lus melting siab lossis reactivity nrog cov cua nyob ib puag ncig.

Dab tsi yog qhov sib txawv ntawm cov txheej txheem sintering?

Muaj ntau hom kev sintering, nrog rau cov khoom siv hauv xeev sintering, kua-theem sintering, activated sintering, microwave sintering, siab-pab sintering, nrog rau cov txheej txheem tshwj xeeb xws li xaiv laser sintering (SLS) thiab electron beam sintering (EBS).Txhua cov txheej txheem muaj nws cov txheej txheem tshwj xeeb thiab raug xaiv raws li cov kev cai tshwj xeeb ntawm cov khoom siv thiab daim ntawv thov.

Yuav ua li cas sintering txhim kho cov khoom ntawm cov khoom?

Sintering txhim kho cov khoom ntawm cov khoom los ntawm kev txhawb cov particle bonding thiab densification.Thaum lub sij hawm sintering txheej txheem, cov hais undergo diffusion, ua rau lub caj dab tsim thiab nce ceev.Qhov no ua rau cov khoom siv kho kom zoo dua qub xws li lub zog, hardness, thiab hnav tsis kam.Tsis tas li ntawd, sintering tuaj yeem ua rau kev txhim kho hluav taws xob, thermal, thiab tshuaj lom neeg nyob ntawm cov khoom siv thiab nws cov muaj pes tsawg leeg.

Puas tuaj yeem sintered qhov chaw yuav machined lossis ua tiav?

Yog lawm, sintered qhov chaw tuaj yeem ua haujlwm ntxiv lossis machining, yog tias xav tau.Thaum sintering tuaj yeem ua tiav qhov ze-net-puab cov khoom, tej zaum yuav muaj qhov xwm txheej uas yuav tsum tau ua ntxiv los yog tom qab ua tiav kom ua tiav cov kev xav tau tshwj xeeb.Machining txheej txheem xws li milling, drilling, lossis sib tsoo tuaj yeem ua haujlwm kom ua tiav qhov kawg qhov ntev lossis qhov chaw tiav.

Dab tsi yog qhov kev txiav txim siab ib puag ncig ntawm sintering?

Sintering feem ntau suav hais tias yog ib qho kev tsim khoom zoo ib puag ncig.Nws siv zog tsawg dua piv rau cov txheej txheem melting thiab casting, thiab nws txo cov khoom pov tseg los ntawm kev tso cai rov qab siv cov hmoov ntau dhau.Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum xav txog qhov cuam tshuam ib puag ncig ntawm cov khoom siv raw siv, nrog rau kev tuav thiab pov tseg ntawm cov khoom lag luam lossis cov khoom pov tseg thaum lub sijhawm ua haujlwm.

Yuav ua li cas sintering pab rau txoj kev loj hlob ntawm cov ntaub ntawv siab heev?

Sintering plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv siab heev.Los ntawm ua tib zoo xaiv thiab tswj cov muaj pes tsawg leeg, particle loj, thiab sintering tsis, nws muaj peev xwm ua kom haum cov khoom ntawm cov khoom tshwm sim.Qhov no tso cai rau kev tsim cov khoom siv siab heev nrog cov yam ntxwv tshwj xeeb, xws li cov khoom siv ua haujlwm siab, cov khoom siv ceramics, lossis cov ntaub ntawv sib xyaw nrog cov khoom sib txuas tshwj xeeb.

Yog tias koj muaj lus nug ntxiv los yog xav tiv tauj nrogHENGKO,

thov koj xav tiv tauj peb ntawm email ntawmka@hengko.com.

Peb yuav zoo siab los pab koj thiab muab cov ntaub ntawv ntxiv uas koj xav tau.

Post lub sij hawm: Aug-14-2020